Carbon fiber reinforced resin based high-performance light composite material and preparation method thereof

A technology for reinforcing resin-based and composite materials, which is applied in the direction of carbon fiber, fiber treatment, radioactive element fiber treatment, etc., and can solve the problems that cannot meet the high performance requirements of composite materials, cannot form mechanical anchoring, and poor wettability of resin matrix. Achieve the effect of increasing interlayer shear strength, improving interface performance and improving surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The high-performance lightweight composite material based on carbon fiber reinforced resin in this embodiment includes the following components in parts by weight: 65 parts of composite resin, 25 parts of modified carbon fiber, 10 parts of glass fiber, 10 parts of curing agent and 15 parts of thinner.

[0032] The above composite resin is composed of 92.5wt% 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl ester and 7.5wt% 4,4-diaminodiphenylmethane tetraglycidylamine .

[0033] The preparation method of the above-mentioned modified carbon fiber is as follows: cleaning the carbon fiber to remove impurities; performing grafting reaction on the graphene acidified by concentrated sulfuric acid and concentrated nitric acid with a silane coupling agent to obtain modified graphene, and modifying Graphene, 4,5-epoxycyclohexane-1,2-diglycidyl dicarboxylate and curing agent are mixed according to the ratio of 3:55:10 by weight to prepare a sizing agent; the carbon fiber is ...

Embodiment 2

[0044] The carbon fiber-reinforced resin-based high-performance lightweight composite material of this embodiment includes the following components in parts by weight: 75 parts of composite resin, 25 parts of modified carbon fiber, 15 parts of glass fiber, 12 parts of curing agent and 20 parts of thinner.

[0045] The above composite resin is composed of 92.5wt% 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl ester and 7.5wt% 4,4-diaminodiphenylmethane tetraglycidylamine .

[0046] The preparation method of the above-mentioned modified carbon fiber is as follows: cleaning the carbon fiber to remove impurities; performing grafting reaction on the graphene acidified by concentrated sulfuric acid and concentrated nitric acid with a silane coupling agent to obtain modified graphene, and modifying Graphene, 4,5-epoxycyclohexane-1,2-diglycidyl dicarboxylate and curing agent are mixed according to the ratio of 3:55:10 by weight to prepare a sizing agent; the carbon fiber is pla...

Embodiment 3

[0057] The carbon fiber-reinforced resin-based high-performance lightweight composite material of this embodiment includes the following components in parts by weight: 70 parts of composite resin, 22 parts of modified carbon fiber, 14 parts of glass fiber, 10.5 parts of curing agent and 17.5 parts of thinner.

[0058] The above composite resin is composed of 92.5wt% 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl ester and 7.5wt% 4,4-diaminodiphenylmethane tetraglycidylamine .

[0059] The preparation method of the above-mentioned modified carbon fiber is as follows: cleaning the carbon fiber to remove impurities; performing grafting reaction on the graphene acidified by concentrated sulfuric acid and concentrated nitric acid with a silane coupling agent to obtain modified graphene, and modifying Graphene, 4,5-epoxycyclohexane-1,2-diglycidyl dicarboxylate and curing agent are mixed according to the ratio of 3:55:10 by weight to prepare a sizing agent; the carbon fiber is...

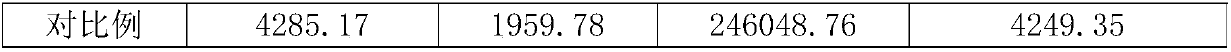

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com