Nano-cellulose dispersing agent as well as preparation method and application of nano-cellulose dispersing agent

A nano-cellulose and dispersant technology, applied in the direction of fibrous fillers, dyed polymer organic compound treatment, inorganic compound addition, etc., can solve the problems of reducing product conductivity, destroying CNT structure, increasing product cost, etc. The effect of increasing, high dispersion efficiency and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

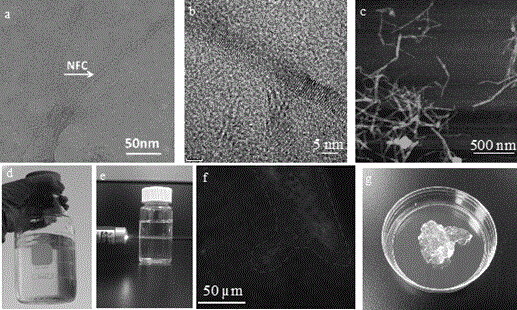

[0023] Example 1 NFC preparation and characterization

[0024] 5g of undried absolute-dry softwood pulp was thoroughly mixed with 78mg of TEMPO and 514mg of NaBr. The reaction was initiated by the addition of 30 mL of 12% NaClO and reacted with stirring at room temperature. The pH value of the system was stabilized at 10.5 by NaOH control. Until the reaction of the remaining NaClO in the system is completely completed. The reacted slurry was washed by filtration until the pH was neutral. The obtained fiber is made into a concentration of 1% and processed under pressure (5-25KPa) by a micro-fluid machine. A transparent nanocellulose (NFC) dispersion was obtained. Store the dispersion in a refrigerator at 4°C until use.

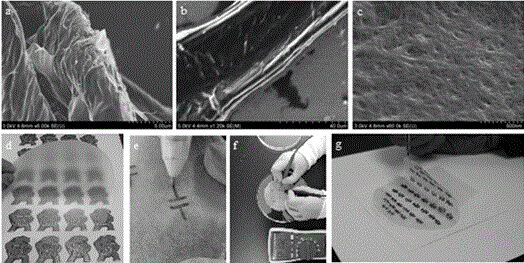

[0025] Scanning Electron Microscope (SEM) Observation: After the sample to be tested is vacuum-dried, glued to the table and vacuum-sprayed with gold, the operating condition voltage is 20kV.

[0026] The length and width of nanocellulose were characteriz...

Embodiment 2

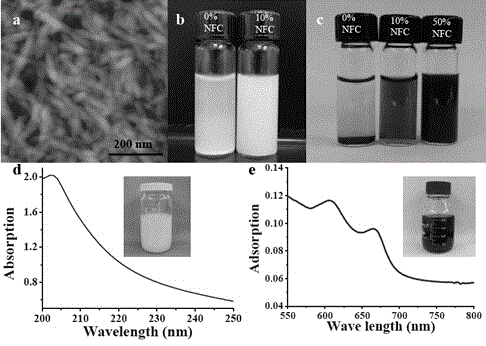

[0030] Example 2 BN, MoS 2 Dispersion and Characterization of CNTs

[0031] First mix commercially available BN powder (Graphene supermarket, Inc.) with 10wt% NFC corresponding to the mass of BN in water. The initial concentration of BN was 5mg / mL. Dispersion is achieved by ultrasonicating the mixed solution in a tank-type ultrasonic instrument (tank-type ultrasonic instrument, ultrasonic power 200W, ultrasonic time 30h). The ultrasonicated solution was centrifuged at 3000r / min for 15min, and then the supernatant was separated. The absorption spectrum of the solution was tested on an ultraviolet spectrometer.

[0032] MoS 2 It exists in the form of ore (SPI Supplies), and the dispersion method is the same as that of BN. The amount of NFC added is MoS 2 10wt% and 50wt% of the mass. The ultrasonic time is 4h, and the centrifugal speed is 5000r / min. The absorption spectrum of the solution was tested on an ultraviolet spectrometer.

[0033] First mix CNT (Carbon Solution)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com