Vertical shaft working face ahead pre-grouting method

A working face and pre-grouting technology, which is applied in shaft equipment, sinking, earthwork drilling, etc., can solve the problems of poor construction quality of grout pads, long auxiliary time, and small number of drilling holes, and reduce the construction period of shafts , Reduce operating costs and speed up drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

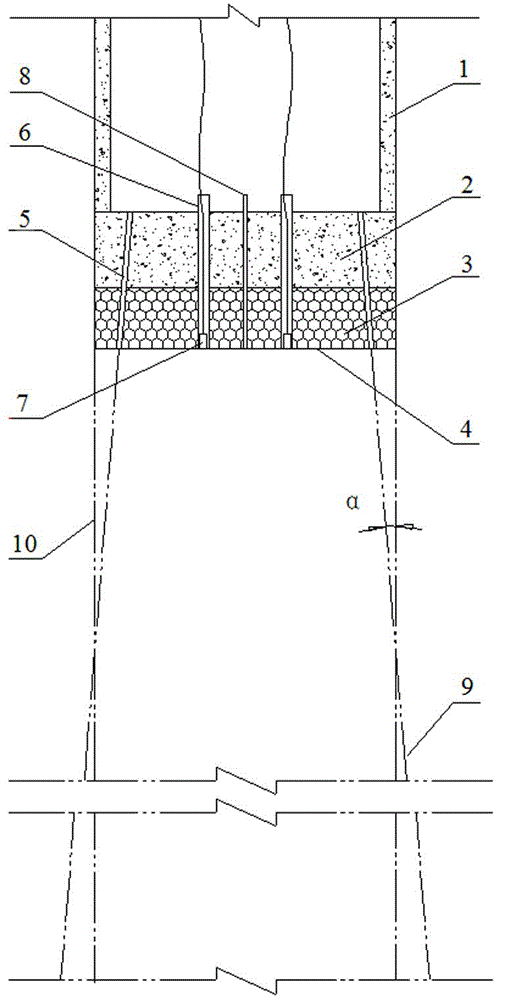

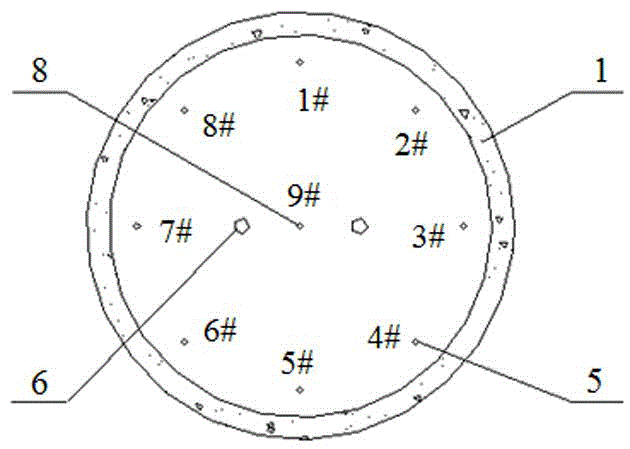

[0047]The return air shaft of the 1 million t / a mining project of the Erdaohe iron ore section of Dahongshan Iron Mine of Kunming Iron and Steel Co., Ltd., the wellhead elevation is 628.3m, the shaft section is circular, the net diameter is φ5.5m, the excavation diameter is φ6.2m, and the shaft neck section The excavation diameter is φ6.5~7.1m, and the depth of the well neck section is 42m. The working face revealed that the rock joints and fissures were developed, the rock was relatively broken, and water gushed out in many places on the working face. When the wellbore was excavated to an elevation of 603.1m (25.2m below the wellhead), the on-site measurement of the wellbore water inflow was 34.57m 3 / h.

[0048] According to the above geological conditions, after repeated analysis, comparison and deliberation, the height of the grouting water blocking section is 40m.

[0049] (1) Grouting parameter design

[0050] 1. Number of grouting holes

[0051] According to the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com