Forged welding valve body structure of side exhaust electromagnetic pressure relief valve

A pressure relief valve, valve body technology, applied in the valve shell structure, valve details, valve device and other directions, can solve problems such as large opening and closing pressure difference, packing and gasket leakage, disassembly and assembly difficulties, etc., to achieve the speed of opening and closing the valve Improved, good structural stability, simple and easy disintegration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

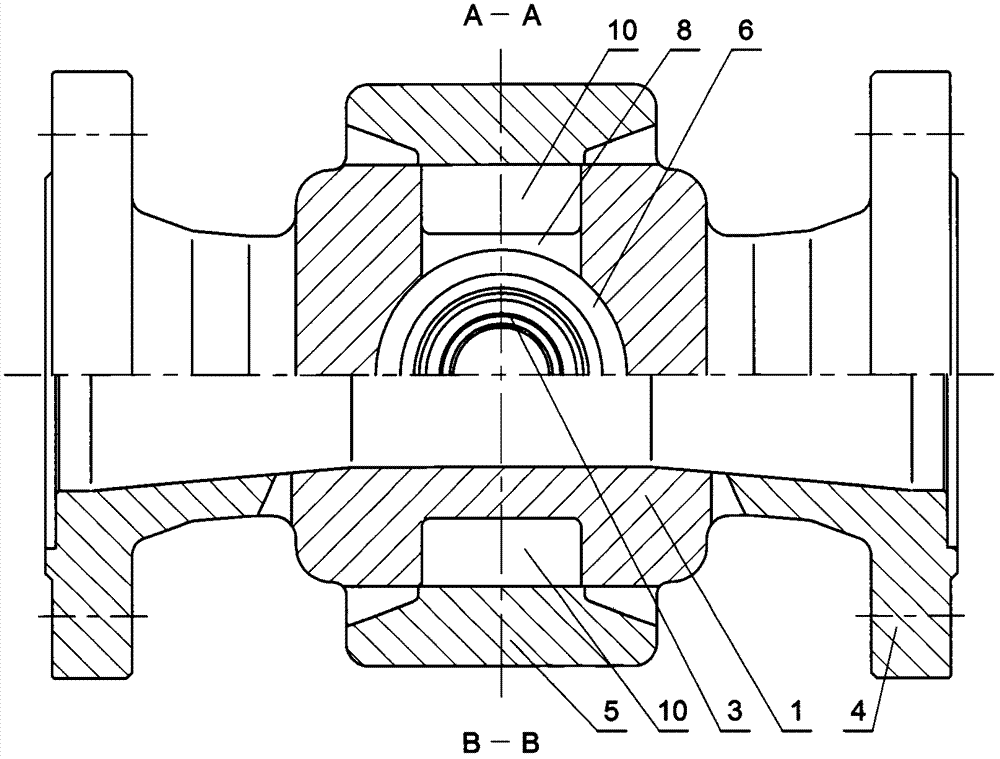

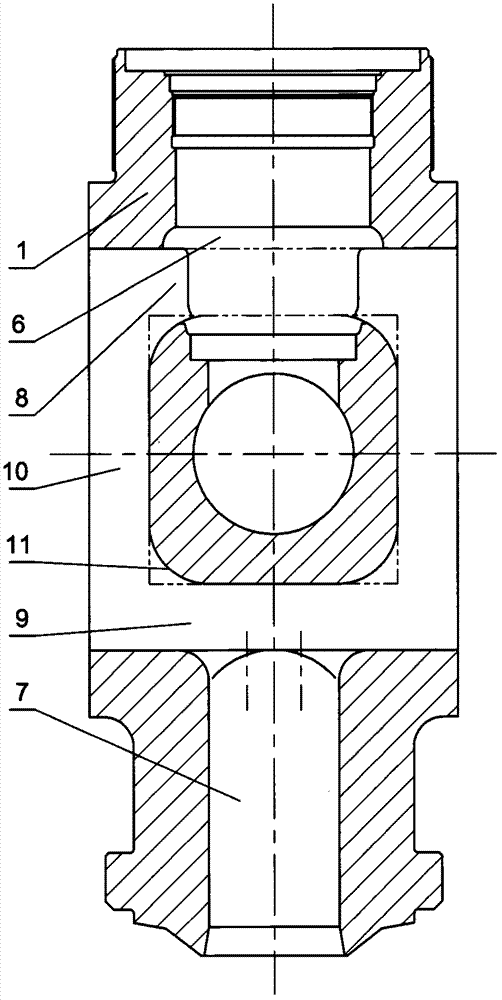

[0031] Such as Figure 4 and Figure 5 , Figure 6 , Figure 7 The forged-welded valve body shown is a double-sided exhaust structure with medium outlet ports on the left and right sides. The valve body flow channel structure is: from the lower side of the medium inlet end upward, through the side channels on the front and rear sides into the valve body In the middle chamber, when the steam is discharged from the middle through hole of the valve seat located on the lower side of the middle chamber of the valve body, the steam is diverted to the left and right sides to the outlet of the medium, through the exhaust elbow connected to the outlet flange and Upright exhaust pipe to a safe place.

[0032] The specific structure of this embodiment is as follows: the lower part of the forged-welded valve body is the installation and connection end of the valve. When the flange connection installation mode is used to connect, a connecting flange needs to be arranged and processed a...

Embodiment 2

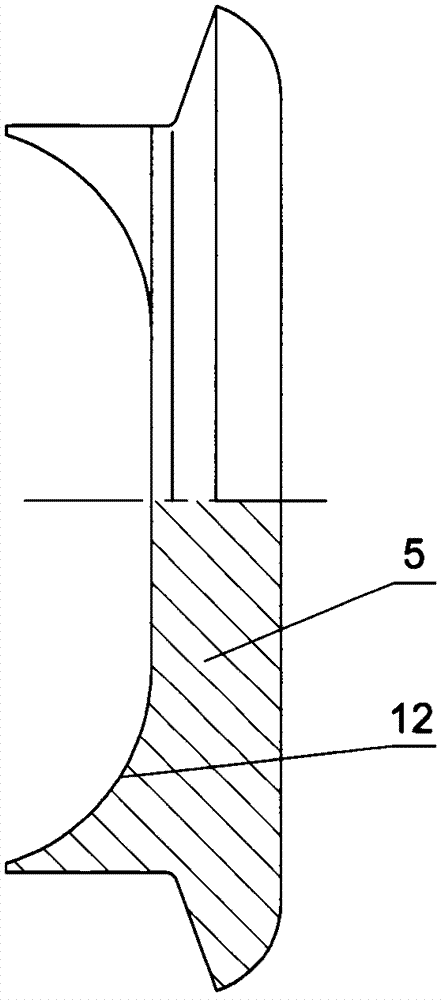

[0044] In the technical solution of the forged-welded valve body of this embodiment, only the specific implementation structure of the side plate (5) is different from that of Embodiment 1, and there is no difference in the structure of the other parts, so this embodiment only focuses on the side plate (5) The specific structure of the embodiment will be discussed, and the rest of the same place as the first embodiment will not be described.

[0045] Such as Figure 13 and Figure 14 , Figure 15 , Figure 16 As shown, the inner surface of the side plate (5) is different from the inner surface of the side plate (5) in Embodiment 1, which is only a simple middle plane plus the cylindrical surfaces on the lower two sides, the inner surface is concave, and the concave The middle part is also composed of a middle plane and a cylindrical surface that is connected with the upper and lower sides and bends inwardly. 5) The inner side surface is formed by scanning along the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com