High-sensitivity bulk acoustic wave silicon microgyroscope

A silicon micro-gyroscope, high-sensitivity technology, applied in the field of micro-gyroscope, can solve the problems of small vibration output, easy to cause tunneling, high operating frequency, meet the requirements of reducing the gap of ultra-high aspect ratio, avoid tunneling, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

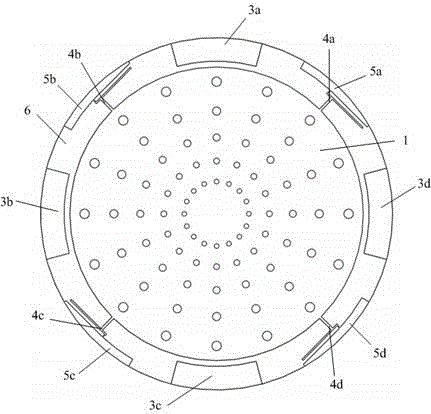

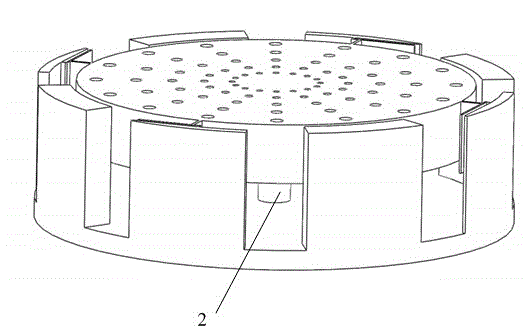

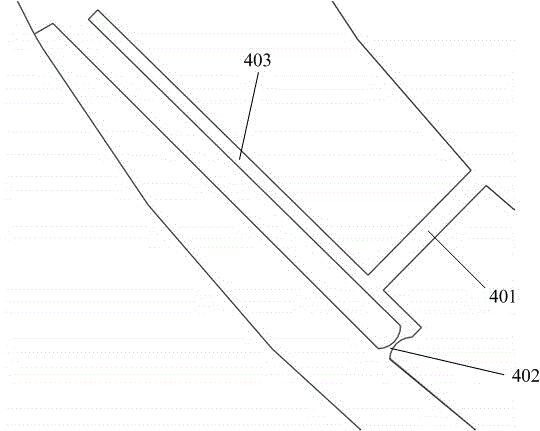

[0021] The following will be combined with figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 and one A specific embodiment further illustrates the high-sensitivity bulk acoustic wave silicon micro-gyroscope of the present invention.

[0022] Such as figure 1 , figure 2 and image 3 The high-sensitivity bulk acoustic wave silicon micro-gyroscope shown is composed of a disc-shaped resonator 1, a support cylinder 2, arc-shaped driving electrodes 3a-3d, detection electrodes 4a-4d with a displacement amplification mechanism, and detection electrode fixing bosses 5a-5d And substrate 6 composition. Gyroscopes are used as Figure 4 and Figure 5 The two in-plane four-amplitude node frequency matching modes of the shown disc-shaped harmonic oscillator 1 are used as the driving mode and the detection mode. The driving mode and the detection mode have the same mode shape, and their radial vibration is positive Intersect, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com