Ampoule for testing temperature field of hearth

A furnace temperature and ampoule technology, applied in the field of sensing temperature measurement, can solve problems such as real-time measurement of tube furnaces, and achieve the effects of simple production, avoiding short circuits and maintaining insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

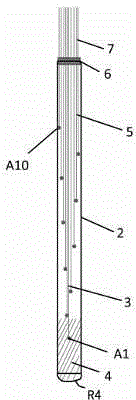

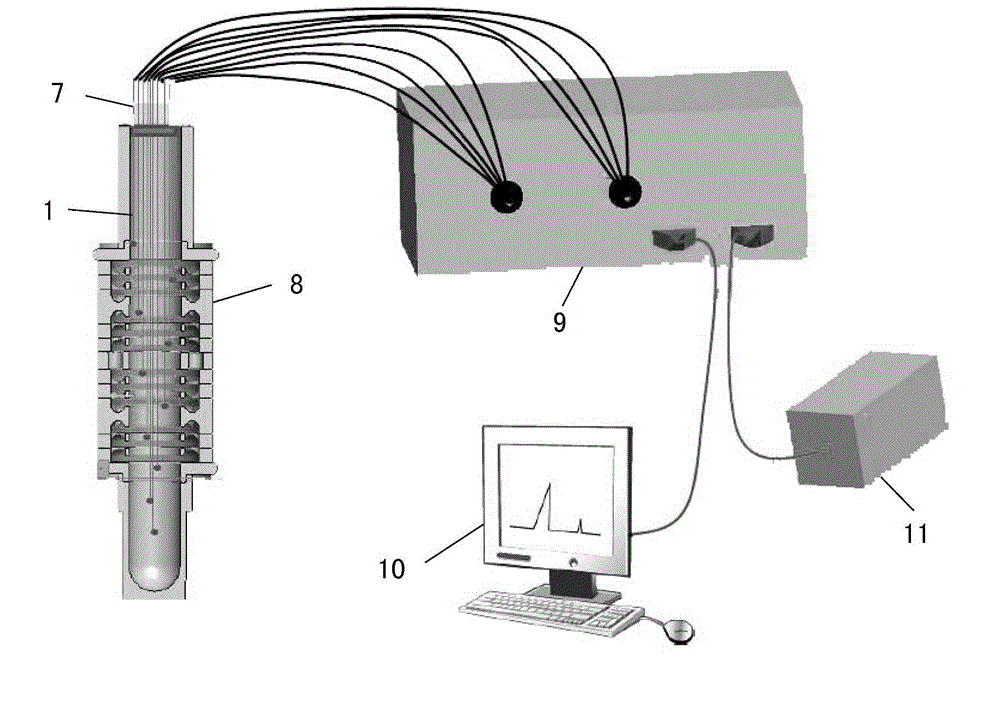

[0049] According to the size and shape requirements of the tube furnace, the outer diameter of the ampoule 1 is designed to be 16mm, the bottom surface of which is rounded and chamfered R4, and the height is 200-300mm. The outer wall of the temperature measuring ampoule is a thin-walled stainless steel sleeve with a wall thickness of 0.08-0.15mm, and the inner wall is a quartz glass tube. The stainless steel sleeve matches the quartz glass tube, but the inner diameter of the stainless steel sleeve is 0.5-1mm larger than the outer diameter of the quartz glass tube.

[0050] Process the aluminum oxide foam brick 4 into the same shape as the bottom of the ampoule 1, the height is 33mm, and the surface in contact with the thermocouple is a plane, dig a 2mm diameter hole in the center of the plane, and the depth is 3mm, and then put it into in a quartz glass tube.

[0051] Put the two bare wires of the positioning thermocouple 3 into the double-hole alumina ceramic tube with an ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com