A thermal desorption device

A thermal desorption and desorber technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of reducing the sample recovery rate and desorption repeatability, inconvenient use, and inability to distill, to improve sensitivity and accuracy. , Easy to fix, small temperature control error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

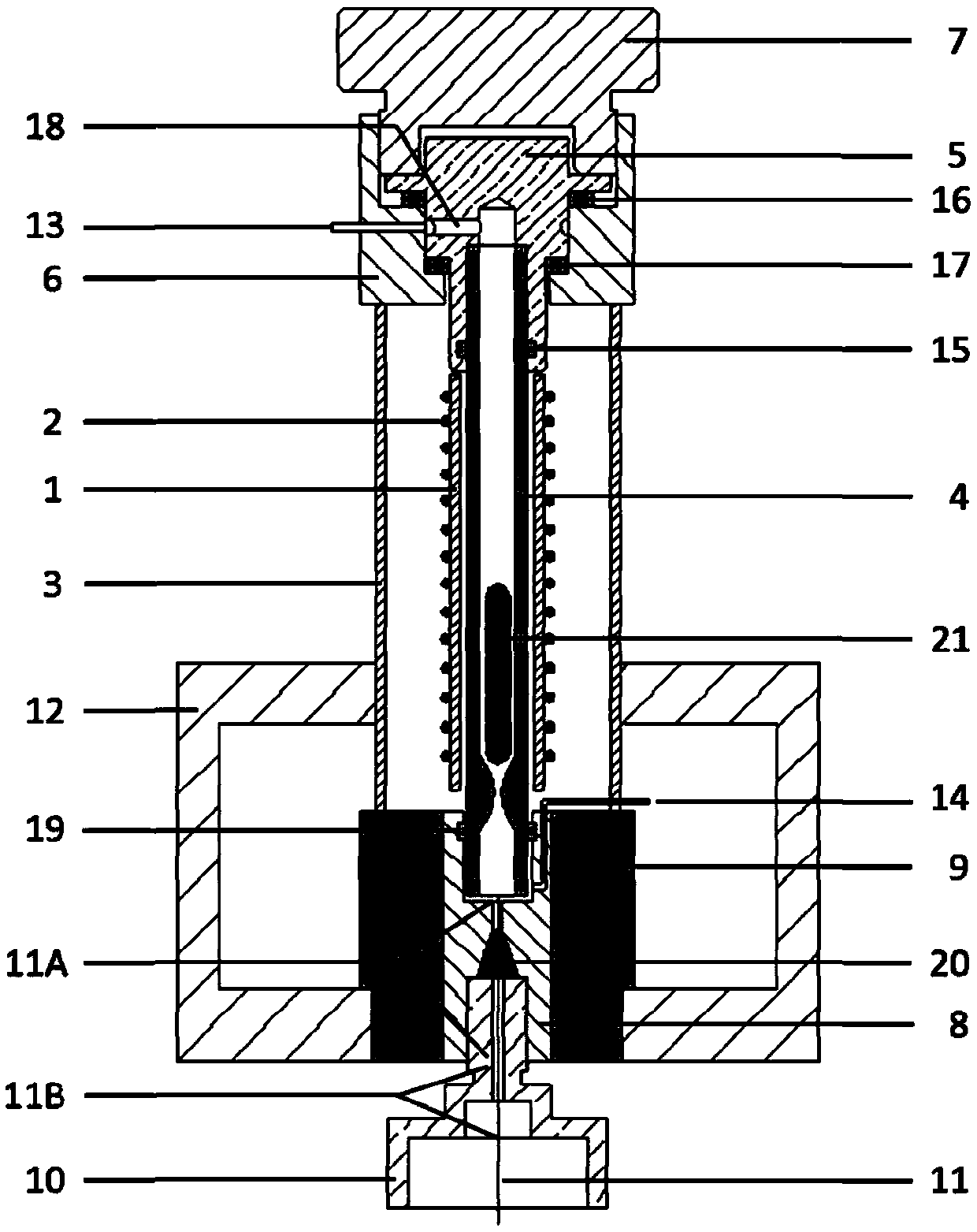

[0033] Such as figure 1 As shown, a thermal desorption device consists of a heating tube 1, a heating wire 2, an outer sleeve 3, an inner liner 4, an inner liner pressure head 5, a desorber upper cover 6, an inner liner pressure cap 7, and an inner liner Liner base 8, liner base heat insulation ring 9, sample transfer tube fastening cap 10, sample transfer tube 11, desorber base 12, desorption purge gas path 13, desorption shunt gas path 14, and temperature control components , characterized by:

[0034] The heating tube 1, the outer sleeve 3 and the inner liner tube 4 are all hollow cylindrical structures with openings at the upper and lower ends, and are arranged coaxially; the outer wall of the heating tube 1 is wound with a heating wire 2 and equipped with a thermocouple , the thermocouple and the heating wire 2 are connected to a temperature controller through wires; the heating tube 1 is placed inside the outer sleeve 3, and the outer sleeve 3 is used to protect the hea...

Embodiment 5

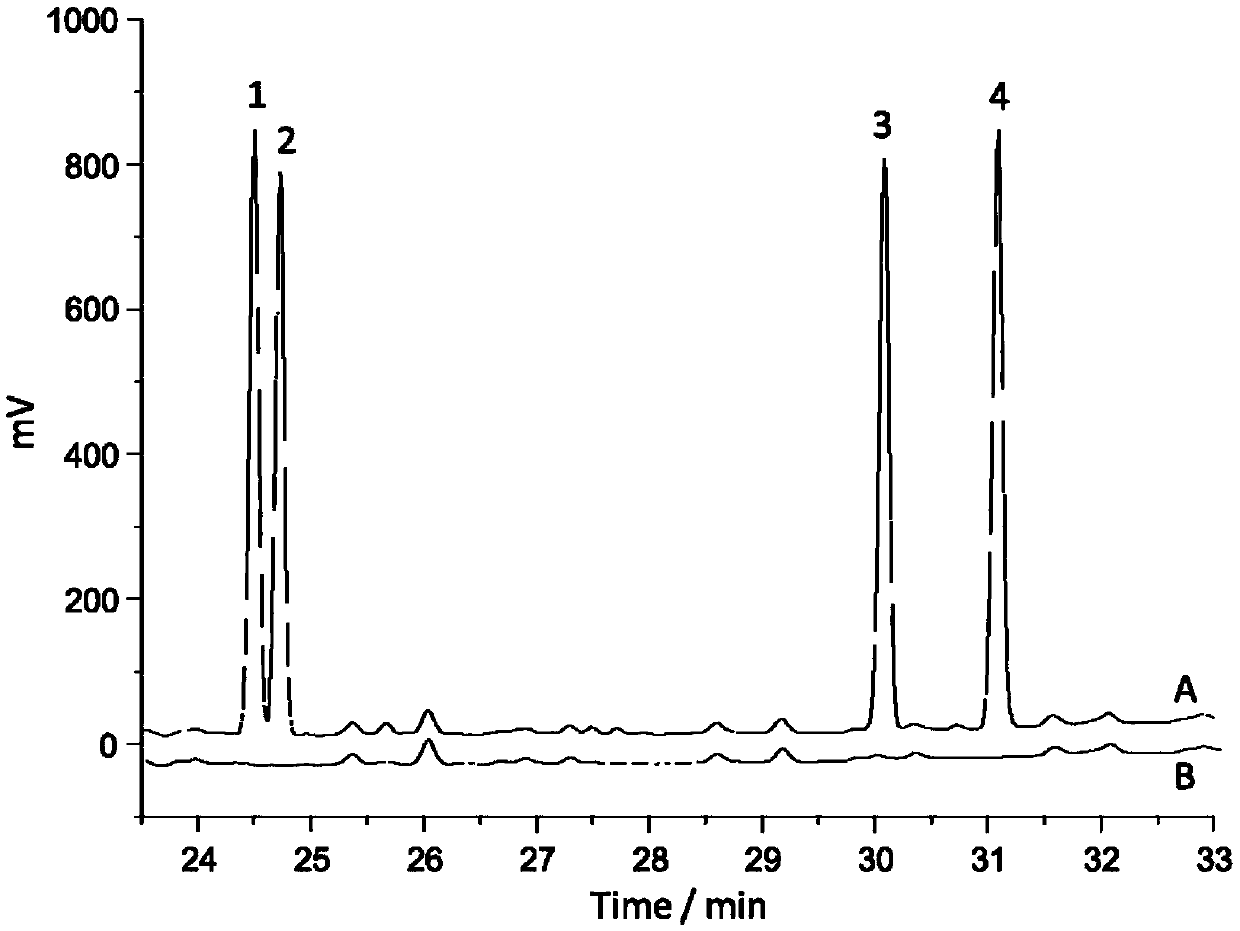

[0055] The thermal desorption device described in Example 1 was used to perform thermal desorption on the solid phase microextraction rod. Use helium as the desorption purge gas, adjust the flow rate to 3mL / min, open the desorption split gas path, and adjust the split ratio to 5:1. The solid-phase microextraction rod is coated with polydimethylsiloxane as a stationary phase with a film thickness of 70 μm. After extracting organochlorine pesticides in 20 mL of milk for 30 minutes, put it into a liner tube and insert it into a thermal desorption device for thermal extraction. Desorption. The desorption conditions are as follows: within 1.5 minutes, the temperature rises from 40°C to 300°C for 5 minutes. Gas chromatography was detected by electron capture detector (ECD), and the lower limit of detection was 0.2ng / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com