Battery pack shell

A technology for battery packs and shells, which is applied to battery pack components, isolation of batteries from their environment, circuits, etc. It can solve problems such as limited strength, needs to be improved, deformation or rupture, etc., to achieve improved performance, good thermal conductivity, super strong resistance corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further illustrate the technical means and effects adopted by the present invention, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

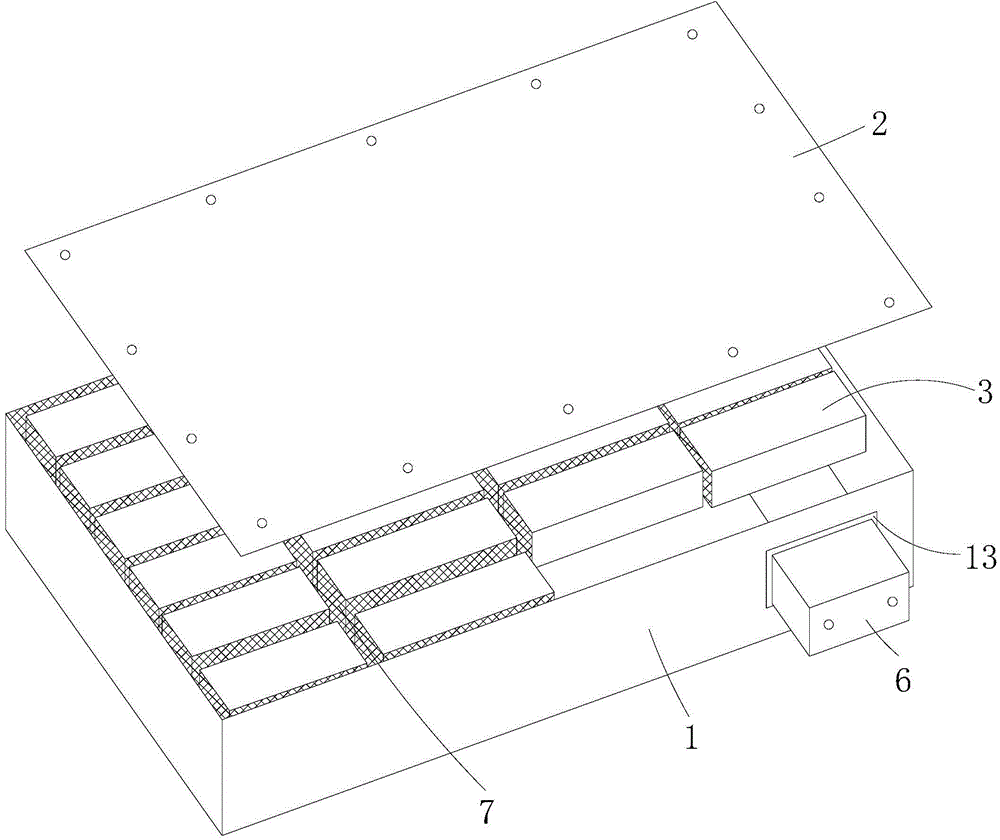

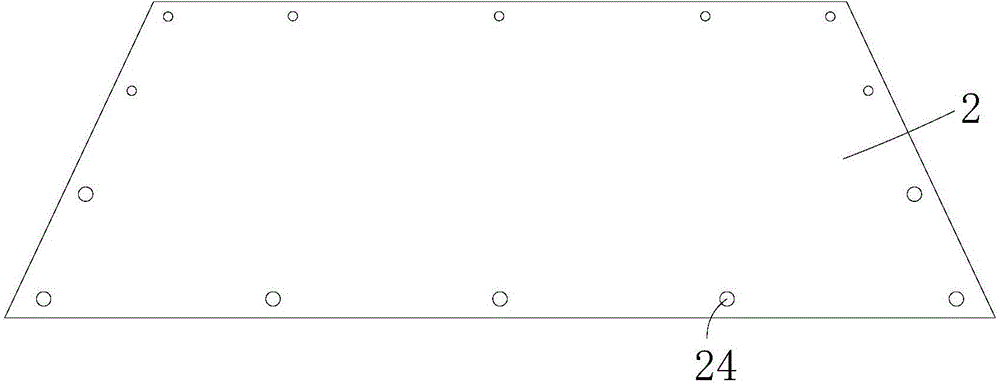

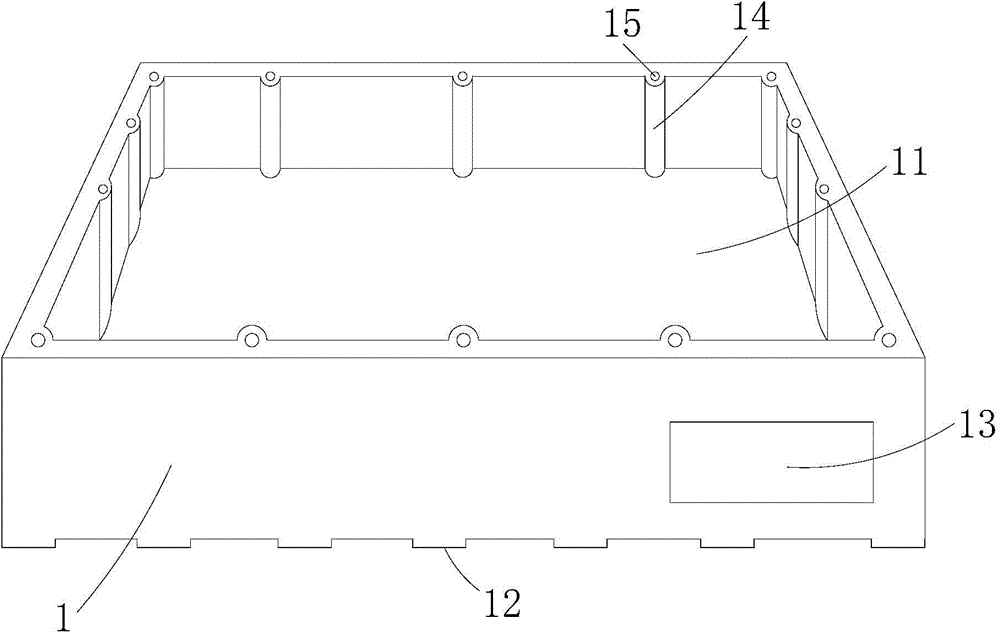

[0017] see figure 1 , the present invention provides a battery pack casing, comprising: a battery pack case 1 and a battery pack bottom plate 2 disposed opposite to the battery pack case 1, the material of the battery pack case 1 is carbon fiber reinforced unsaturated resin and The magnesium-aluminum alloy composite material covered by the glass fiber composite material, the material of the battery pack bottom plate 2 is a carbon fiber reinforced titanium-coated magnesium-aluminum alloy composite material.

[0018] Among them, the magnesium-aluminum alloy composite material covered by carbon fiber-reinforced unsaturated resin and glass fiber composite material and the carbon fiber-reinforced titanium-coated magnesium-aluminum alloy composite mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com