Head maxillofacial bone implant and method for quickly molding same

A molding method and bone implantation technology, applied in the direction of bone implants, prostheses, medical science, etc., can solve the problems of displacement, troublesome postoperative complications, lack of technical and patent documents, etc., and achieve good tissue strength and Stability, avoidance of raw material waste, prevention of extrusion and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

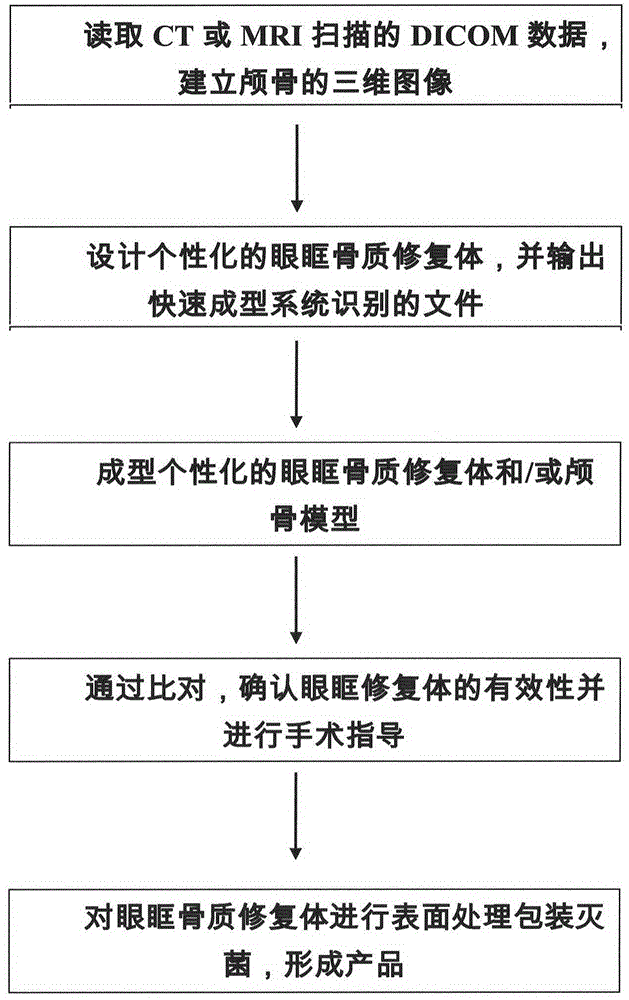

[0057] Research methods Such as figure 2 As shown, the main steps are as follows:

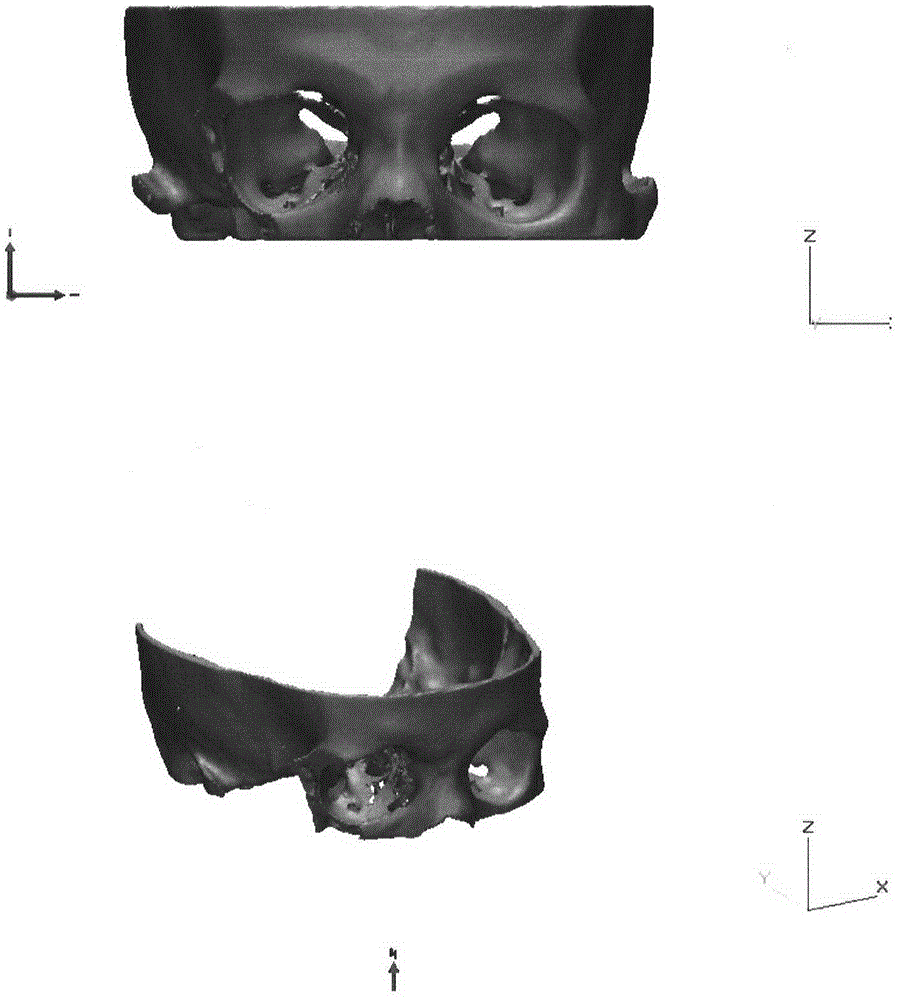

[0058] ① Using clinical DICOM files obtained from CT scans to reconstruct the three-dimensional skull picture picture.

[0059] ②Design a personalized bone defect restoration, and output the file recognized by the rapid prototyping system.

[0060] ③Personalized bone defect restoration and skull model with molding design.

[0061] ④ Through comparison, confirm the effectiveness of the bone defect restoration and provide surgical guidance.

[0062] The specific implementation process is described as follows:

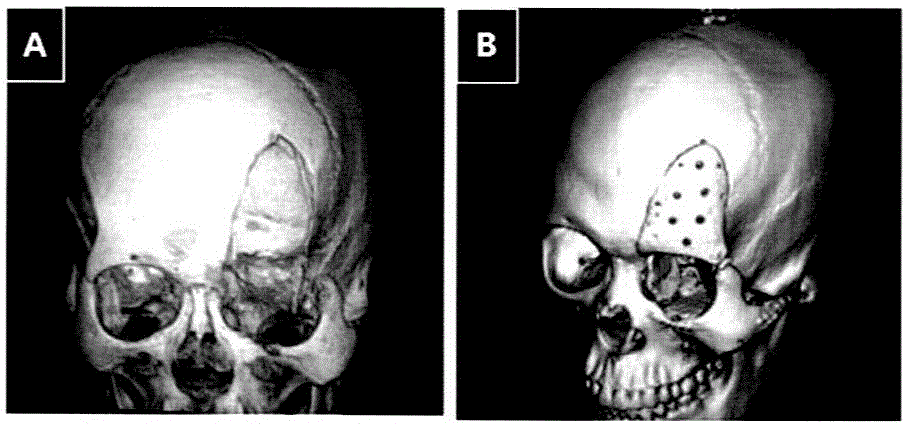

[0063] In the first step, the patient suffered a fracture of the left orbital wall due to various reasons and went to the doctor. The data files were obtained through CT scanning, and the patient's skull was reconstructed. Such as image 3 shown.

[0064] In the second step, through computer-aided design methods such as segmentation, mirroring, fusion, and surface reconstructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com