Viscous paste extruding and dehydrating device

A technology for extrusion dehydration and paste, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve problems such as dehydration of viscous paste, achieve less heat energy consumption, convenient and flexible adjustment, The effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

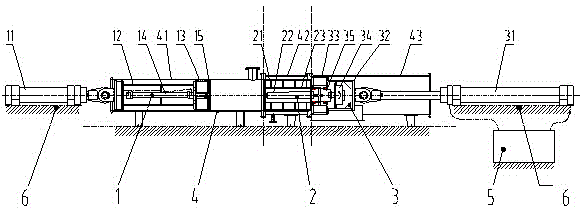

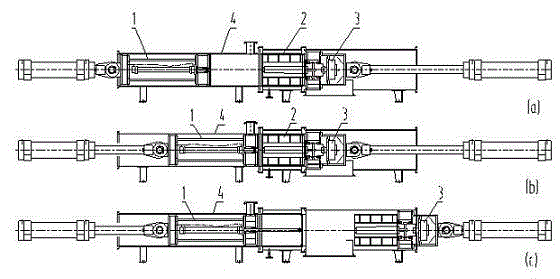

[0025] Please refer to the attached Figure 1 to Figure 3 As shown, the present invention is a viscous paste extrusion dehydration device, which is composed of a dehydration piston 1, a filter element scraper device 2, an end face seal 3, a dehydration container 4 and a hydraulic system 5. The installation surface 6 is a process installation surface, which is not included in the device.

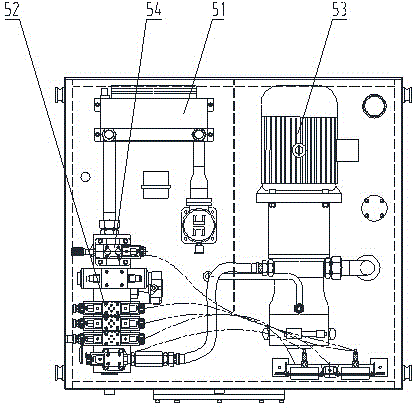

[0026] Wherein, the dehydration piston 1 is installed in the dehydration container 4, and is driven by the dehydration cylinder 11 to make a linear reciprocating motion along the axial direction of the dehydration container; Make a circular motion in the dehydration container; the end face seal 3 is installed in the dehydration container 4, and makes a linear reciprocating motion along the axial direction of the dehydration container under the drive of the drive cylinder; the hydraulic system 5 is installed in the viscous paste extruder On the mounting surface 6 outside the pressure dehydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com