Modification method of graphene/bismuth composite material and screen printing electrode

A technology of screen printing electrodes and composite materials, applied in the direction of electrochemical variables of materials, etc., can solve the problems of poor repeatability of electrochemical sensor measurement, and achieve the effects of large-scale production, convenient synthesis, and rapid response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

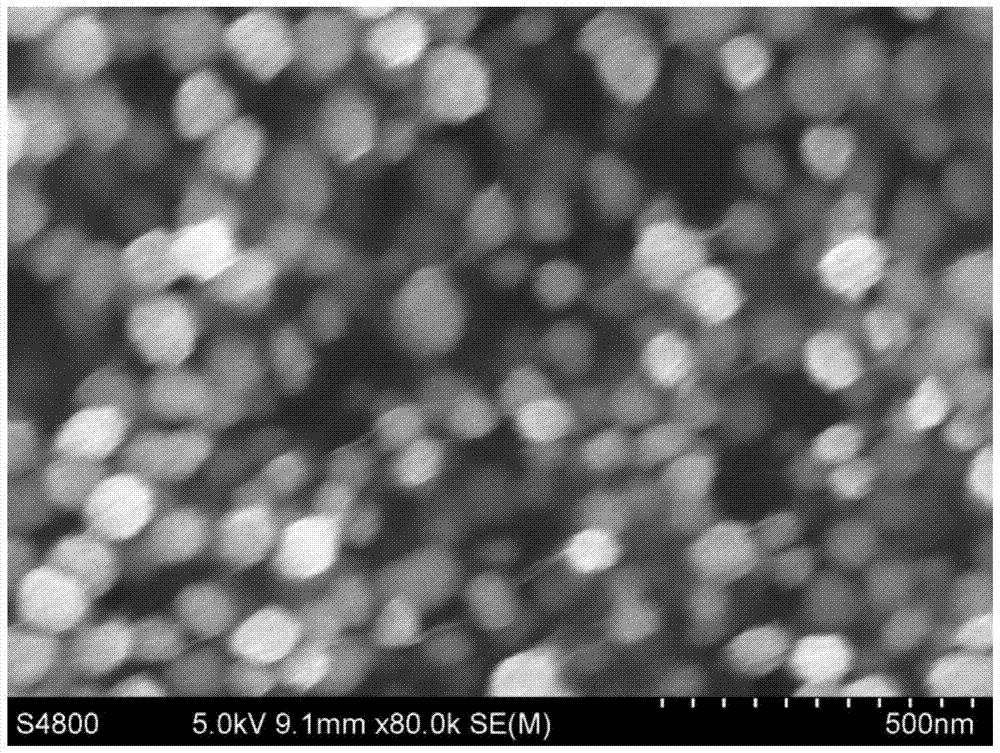

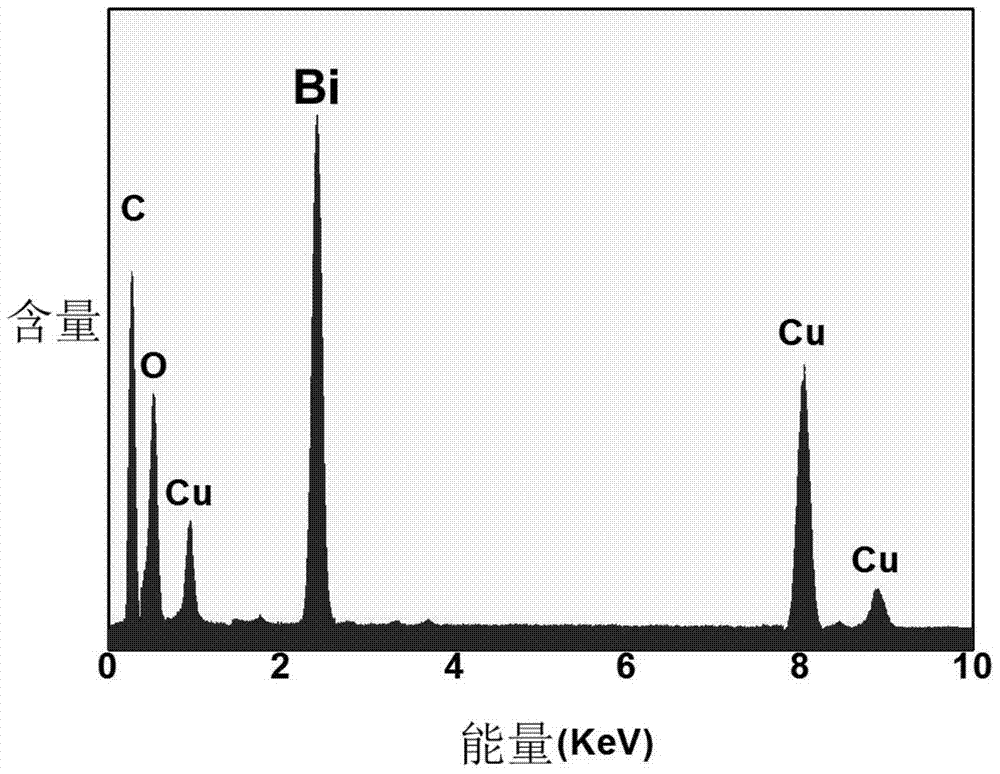

[0027] First, bismuth nitrate, graphene oxide and sodium borohydride were dissolved in water by ultrasonic wave at 300W to obtain a mixed solution with a concentration of 5mmol / L bismuth nitrate, 100mg / L graphene oxide and 5mmol / L sodium borohydride. Next, the above mixed liquid was transferred to a microwave flask, and a uniform mixed solution was formed by ultrasonic waves, and reacted under 500W microwave heating for 10 minutes to obtain a graphene / bismuth composite material. The above-mentioned graphene / bismuth composite material and 0.2mL 0.5% w / w Dupont D520Nafion solution were mixed evenly and coated on the working area of the working electrode of the screen-printed electrode, and dried at 60°C to form a film to obtain a modified screen-printed electrode. The electrodes were activated by soaking with 20 wt% hydrazine hydrate for 8 min before use. In this example, a graphene / bismuth composite material containing bismuth nanospheres of 50-100 nm is attached to the upper...

Embodiment 2

[0029] First, bismuth nitrate, graphene oxide and sodium borohydride were dissolved in water by ultrasonic wave at 500W to obtain a mixed solution with a concentration of 1mmol / L bismuth nitrate, 100mg / L graphene oxide and 2mmol / L sodium borohydride. Next, the above mixed liquid was transferred to a microwave flask, and a uniform mixed solution was formed by ultrasonic waves, and reacted under 800W microwave heating for 10 minutes to obtain a graphene / bismuth composite material. The above-mentioned graphene / bismuth composite material and 0.2mL 0.5% w / w Dupont D520Nafion solution were mixed evenly and coated on the working area of the working electrode of the screen-printed electrode, and dried at 60°C to form a film to obtain a modified screen-printed electrode. The electrodes were activated by soaking with 25 wt% hydrazine hydrate for 5 min before use. In this example, a graphene / bismuth composite material containing 20-50 nm bismuth nanospheres is attached to the upper sur...

Embodiment 3

[0031] First, bismuth nitrate, graphene oxide and sodium borohydride were dissolved in water by ultrasonic wave at 50W to obtain a mixed solution with a concentration of 1mmol / L bismuth nitrate, 100mg / L graphene oxide and 5mmol / L sodium borohydride. Next, the above mixed liquid was transferred to a microwave flask, and a uniform mixed solution was formed by ultrasonic waves, and reacted under 800W microwave heating for 5 minutes to obtain a graphene / bismuth composite material. The above-mentioned graphene / bismuth composite material and 0.2mL 0.5% w / w Dupont D520Nafion solution were mixed evenly and coated on the working area of the working electrode of the screen-printed electrode, and dried at 60°C to form a film to obtain a modified screen-printed electrode. The electrodes were activated by soaking with 5 wt% hydrazine hydrate for 15 min before use. In this example, a graphene / bismuth composite material containing 10-30 nm bismuth nanospheres is attached to the upper surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com