A water treating agent and a preparing method thereof

A water treatment agent and calcination treatment technology, applied in the field of composite water treatment agent and its preparation, can solve the problems of COD reaching the standard discharge, difficult to achieve treatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

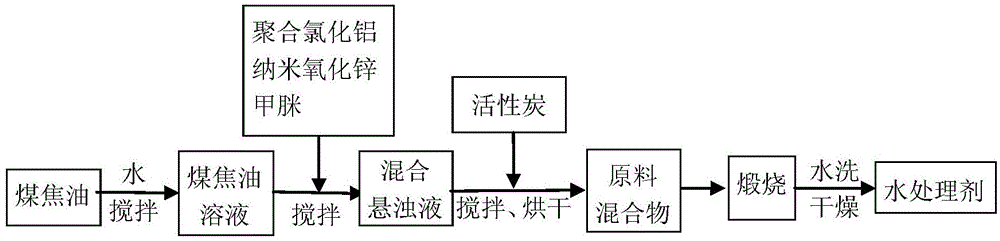

Method used

Image

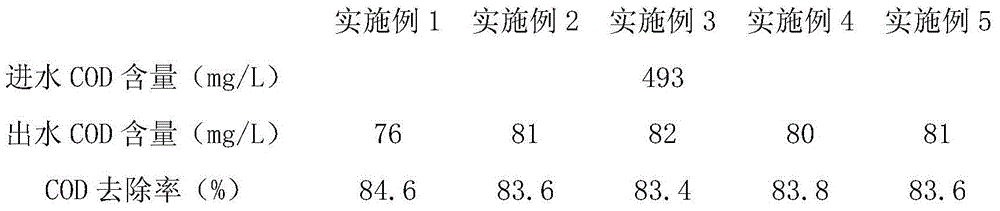

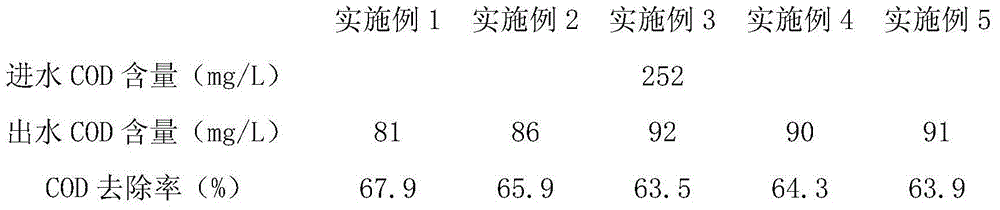

Examples

Embodiment 1

[0085] 1. Preparation of activated lignite-based activated carbon

[0086] (1-1) First, add lignite-based activated carbon into water, heat, boil, and wash with water, wherein the ratio of lignite-based activated carbon weight to water volume is 1:1.5; wash with water for 10 minutes and then filter while hot to obtain water-washed activated carbon;

[0087] (1-2) After the water-washed activated carbon is cooled to room temperature (15-30°C), it is added to the hydrochloric acid solution, acid-soaked and filtered under stirring to obtain acid-soaked activated carbon, wherein the mass percent concentration of the hydrochloric acid solution is 10 %, the ratio of the weight of lignite-based activated carbon to the volume of hydrochloric acid solution is 1:6.5; the stirring rate is 80rpm, and the acid soaking time is 8h;

[0088] (1-3) Acid-soaked activated carbon is rinsed with distilled water until the effluent is neutral to obtain neutral activated carbon washed with distilled ...

Embodiment 2

[0101] 1. Preparation of activated lignite-based activated carbon

[0102](1-1) First, add lignite-based activated carbon into water, heat, boil, and wash with water, wherein the ratio of the weight of lignite-based activated carbon to the volume of water is 1:1; after 8 minutes of water-washing, filter while it is hot to obtain water-washed activated carbon;

[0103] (1-2) After the water-washed activated carbon is cooled to room temperature (15-30°C), it is added to the hydrochloric acid solution, acid-soaked and filtered under agitation to obtain acid-soaked activated carbon, wherein the mass percent concentration of the hydrochloric acid solution is 8 %, the ratio of the weight of lignite-based activated carbon to the volume of hydrochloric acid solution is 1:5; the stirring rate is 100rpm, and the acid soaking time is 9h;

[0104] (1-3) Acid-soaked activated carbon is rinsed with distilled water until the effluent is neutral to obtain neutral activated carbon washed with ...

Embodiment 3

[0117] 1. Preparation of activated lignite-based activated carbon

[0118] (1-1) First, add lignite-based activated carbon into water, heat, boil, and wash with water, wherein the ratio of the weight of lignite-based activated carbon to the volume of water is 1:2; after 15 minutes of water-washing, filter while hot to obtain water-washed activated carbon;

[0119] (1-2) After the water-washed activated carbon is cooled to room temperature (15-30° C.), it is added to the hydrochloric acid solution, acid-soaked and filtered under stirring to obtain acid-soaked activated carbon, wherein the mass percent concentration of the hydrochloric acid solution is 12 %, the ratio of the weight of lignite-based activated carbon to the volume of hydrochloric acid solution is 1:8; the stirring rate is 50rpm, and the acid soaking time is 7h;

[0120] (1-3) Acid-soaked activated carbon is rinsed with distilled water until the effluent is neutral to obtain neutral activated carbon washed with dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com