Chelated calcium fertilizer and preparation method thereof

A technology of chelating calcium fertilizer and calcium nitrate, applied in the direction of nitrogen fertilizer, magnesium fertilizer, inorganic fertilizer, etc., can solve the problems that plants cannot absorb nutrients well, the effective utilization rate of fertilizer is not high, and the pipeline is easy to block, so as to improve and Correcting physiological diseases, good resistance to hard water, easy to absorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

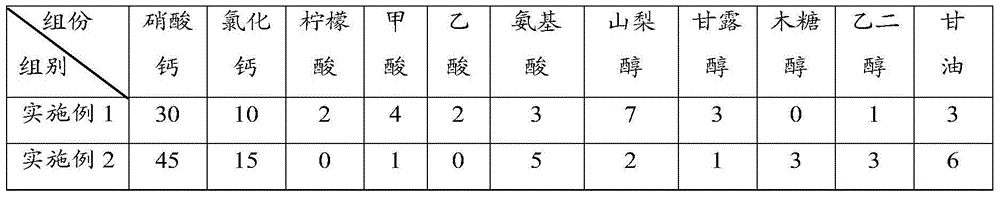

[0030] In this embodiment, the specific dosage of raw materials is formulated according to the following table 1. The specific preparation method is: first dissolve calcium nitrate and calcium chloride with an appropriate amount of water to form a uniform mixture, and pour it into a heating jacket and stirring device. In the reaction kettle, the temperature is controlled at 40-50°C, after adding citric acid, formic acid, acetic acid, and amino acid in sequence, start the stirring device to stir for a period of time to obtain the chelated calcium premix, and finally adjust the temperature to 60-80°C, Add sorbitol, mannitol, xylitol, ethylene glycol and glycerin and stir for a period of time, then cool to room temperature 20-30°C to obtain liquid chelated calcium fertilizer; pour the liquid chelated calcium fertilizer out of the reactor for production After a series of post-processing steps such as granule drying, crushing, and sieving, the final product is obtained.

[0031] Ta...

Embodiment 3-4

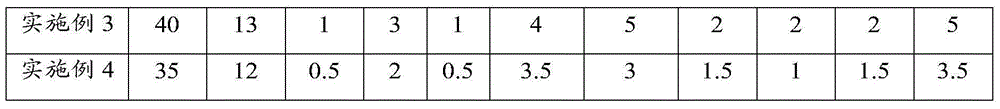

[0035]In this embodiment, the specific dosage of raw materials is formulated according to the following table 2. The specific preparation method is: first dissolve calcium nitrate and calcium chloride with appropriate amount of water to form a uniform mixture, and pour it into a heating jacket and stirring device. In the reaction kettle, the temperature is controlled at 40-50°C, after adding citric acid, formic acid, acetic acid, and amino acid in sequence, start the stirring device and stir for 70-80min under the condition of stirring rate of 200-300rad / min to obtain the chelated calcium preform. Mixture, finally adjust the temperature to 60-80°C, add sorbitol, mannitol, xylitol, ethylene glycol and glycerin, stir for 15-20min at a stirring rate of 300-400rad / min and then cool to The room temperature is 20-30°C to obtain the liquid chelated calcium fertilizer; the liquid chelated calcium fertilizer is poured out from the reaction kettle, and the final product is obtained after...

Embodiment 5-6

[0041] In this embodiment, the specific dosage of raw materials is formulated according to the following table 3. The specific preparation method is: first dissolve calcium nitrate and calcium chloride with an appropriate amount of water to form a uniform mixture, and pour it into a heating jacket and stirring device. In the reaction kettle, the temperature is controlled at 40-50°C, after adding citric acid, formic acid, acetic acid, and amino acid in sequence, start the stirring device and stir for 70-80min under the condition of stirring rate of 200-300rad / min to obtain the chelated calcium preform. Mixture, finally adjust the temperature to 60-80°C, add sorbitol, mannitol, xylitol, ethylene glycol and glycerin, stir for 15-20min at a stirring rate of 300-400rad / min and then cool to The liquid chelated calcium fertilizer is obtained at room temperature of 20-30°C; the liquid chelated calcium fertilizer is poured out from the reactor, and the liquid chelated calcium fertilizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com