2-4-dichloronitrobenzene synthesis method utilizing micro-channel reactor

A technology of microchannel reactor and dichloronitrobenzene, which is applied in the preparation of nitro compounds and organic chemistry to achieve the effects of ensuring safety, improving selectivity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

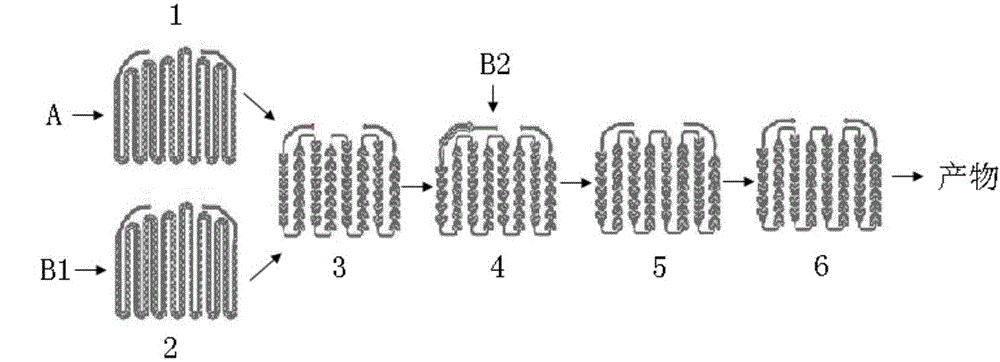

[0032] (1) Device: Corning high-throughput microchannel reactor. The reactor is configured as image 3 As shown, microchannel reactor 1-4 is the first temperature zone, microchannel reactor 5-6 is the second temperature zone, and microchannel reactor 4 is supplemented with mixed acid feed. Microchannel reactor 1-2 is used for precooling mixed acid and m-dichlorobenzene.

[0033] (2) prepare mixed acid according to mass ratio nitric acid: sulfuric acid 1: 1.8, the flow rate ratio of setting each advection pump A, B1, B2 is m-dichlorobenzene: mixed acid: mixed acid=1: 0.7: 0.5, this time dichlorobenzene and The molar ratio of nitric acid is 1:1.2, the temperature of the first temperature zone is 10°C, the temperature of the second temperature zone is 35°C, the reaction residence time in each microchannel reactor is 30s, and the system pressure can reach 1.0Mpa. After the product comes out from the outlet, it is extracted and washed with water. According to GC analysis, the con...

Embodiment 2

[0035] (1) Device: Corning high-throughput microchannel reactor. The reactor is configured as image 3 As shown, microchannel reactor 1-4 is the first temperature zone, microchannel reactor 5-6 is the second temperature zone, and microchannel reactor 4 is supplemented with mixed acid feed. Microchannel reactor 1-2 is used for precooling mixed acid and m-dichlorobenzene.

[0036] (2) prepare mixed acid according to mass ratio nitric acid: sulfuric acid 1: 1.8, the flow rate ratio of setting each advection pump A, B1, B2 is m-dichlorobenzene: mixed acid: mixed acid=1: 0.7: 0.5, this time dichlorobenzene and The molar ratio of nitric acid is 1:1.2, the temperature of the first temperature zone is 15°C, the temperature of the second temperature zone is 30°C, the reaction residence time in each microchannel reactor is 30s, and the system pressure can reach 1.0Mpa. After the product comes out from the outlet, it is extracted and washed with water. According to GC analysis, the con...

Embodiment 3

[0038] (1) Device: Corning high-throughput microchannel reactor. The reactor is configured as image 3 As shown, microchannel reactor 1-4 is the first temperature zone, microchannel reactor 5-6 is the second temperature zone, and microchannel reactor 4 is supplemented with mixed acid feed. Microchannel reactor 1-2 is used for precooling mixed acid and m-dichlorobenzene.

[0039](2) prepare mixed acid according to mass ratio nitric acid: sulfuric acid 1: 1.8, the flow rate ratio of setting each advection pump A, B1, B2 is m-dichlorobenzene: mixed acid: mixed acid=1: 0.7: 0.5, this time dichlorobenzene and The molar ratio of nitric acid is 1:1.2, the temperature of the first temperature zone is 55°C, the temperature of the second temperature zone is 45°C, the reaction residence time in each microchannel reactor is 30s, and the system pressure can reach 1.0Mpa. After the product comes out from the outlet, it is extracted and washed with water. According to GC analysis, the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com