Thermal storage stable rubber-plastic composite modified asphalt and preparation method thereof

A composite modified asphalt and thermal storage technology, applied in building components, building thermal insulation materials, buildings, etc., can solve problems such as restricting the popularization and application of modified asphalt, thermal storage stability of asphalt, and increasing the cost of modified asphalt. Achieve good high temperature anti-rutting, not easy to segregate, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment, but does not limit the present invention thereby.

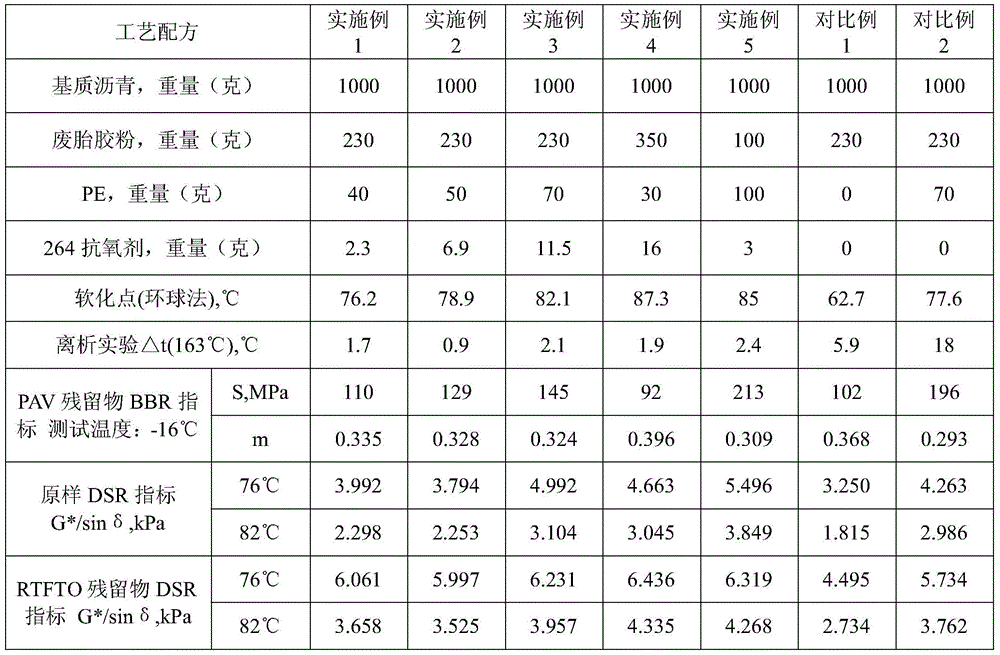

[0021] According to the method and steps described in this patent, 5 composite modified asphalt samples were prepared respectively, and the specific formula and evaluation results are shown in Examples 1-5 in Table 1; 2 comparative samples prepared by the same method and steps, the specific The formulation and evaluation results are shown in Comparative Examples 1 and 2 in Table 1. The specific preparation method is operated according to the following steps:

[0022] (1) Heat the base asphalt to a hot-melt state, and the processing temperature range is 145°C to 160°C. Slowly add the weighed mixture of waste tire rubber powder, PE and 264 antioxidant, and the adding time should be controlled within 10 minutes. Stir with low speed shear to make it evenly mixed, the shear rate is 1500-2000r / min, and the temperature of the mixture is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com