A silicon wafer fine polishing liquid capable of prolonging the service life of polishing pads

A technology of silicon wafer refining and polishing liquid, which is applied in the manufacture of polishing compositions containing abrasives, electrical components, semiconductor/solid-state devices, etc., which can solve the clogging of pores in the hair follicles of polishing pads, affect the service life of polishing pads, and increase polishing particles. Deposition and other problems to achieve the effect of improving rotation, prolonging service life and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

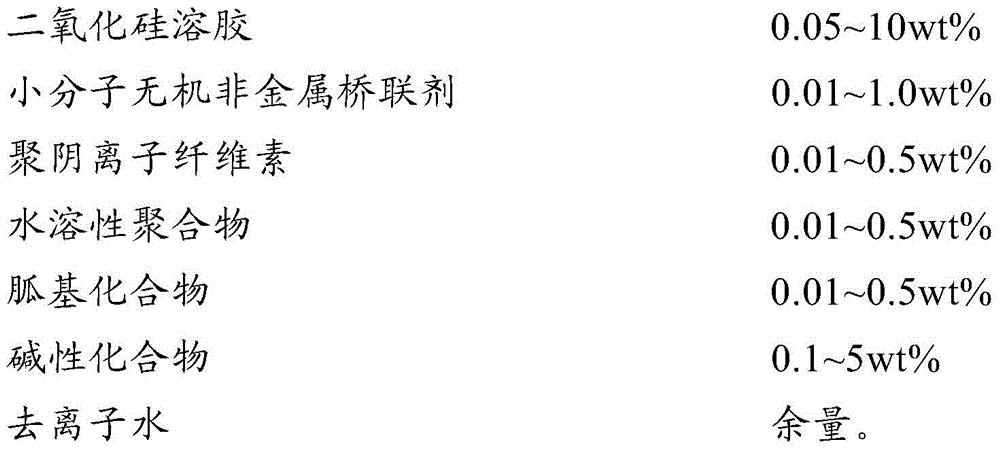

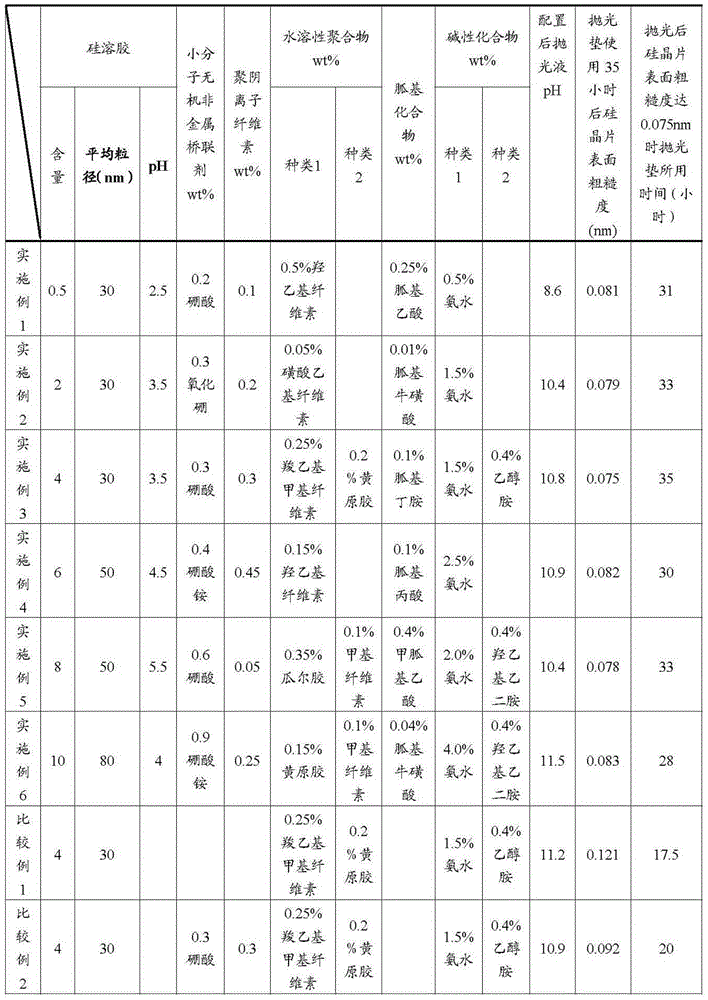

[0028] The present invention will be further described below by way of examples, which certainly should not be construed as limiting the scope of the present invention in any case.

[0029] The specific added components and edge polishing results are shown in the attached table. Unless otherwise specified, the content of the added compounds is calculated by weight.

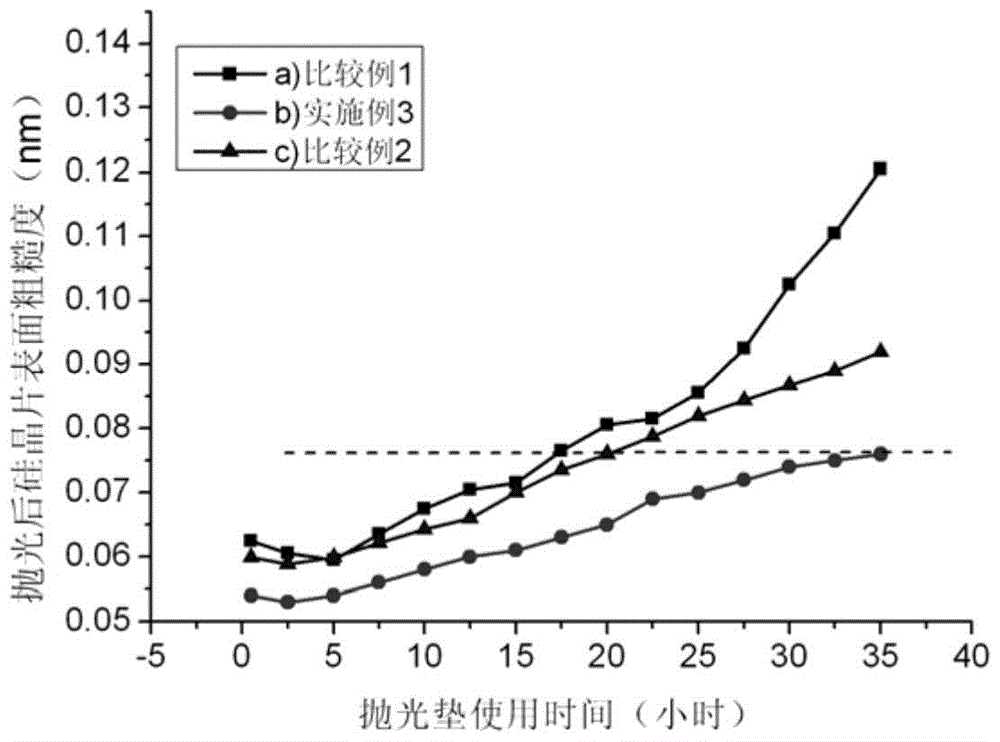

[0030] Test Example

[0031] The polishing composition after configuration is used for polishing experiment, and each polishing time is 30min, carries out continuous polishing, and polishing pad is scrubbed 5min between each polishing, and for uniform evaluation impact on polishing pad, the wafer surface roughness after polishing The time taken for the polishing pad to reach 0.075nm and the surface roughness value of the silicon wafer after the polishing pad has been used for 35 hours are used as reference. The specific polishing experimental parameters are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com