A kind of preparation method of cemented carbide cutting tool material

A technology of cemented carbide and cutting tools, which is applied in the field of preparation of materials for cemented carbide cutting tools, can solve the problems of affecting cutting quality, sharpness and toughness of the knife edge, poor wear resistance, etc., achieve good cutting effect, small cutting resistance, reduce grossly wasted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

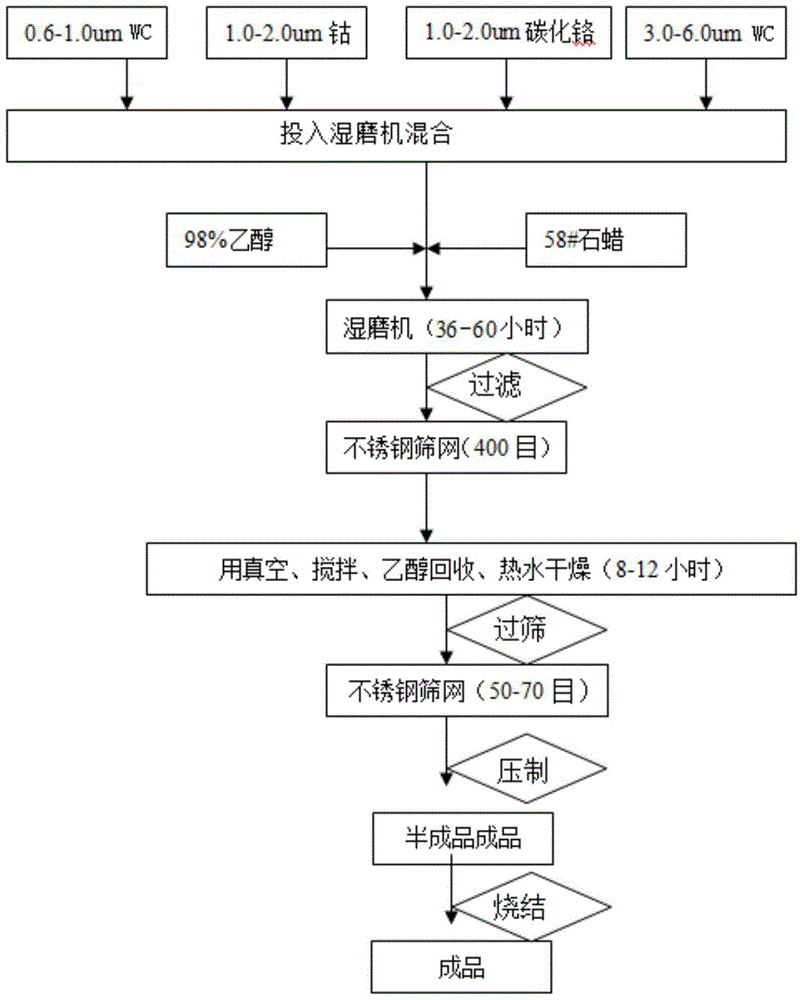

[0045] Such as figure 1 Shown, a kind of preparation method of cemented carbide cutting tool material, comprises the steps:

[0046] (1) The diameters of selected specifications are 10.5cm, 9.5cm, 8.5cm, 7.3cm, 5.5cm, the heights are 17cm, 16.7cm, 16.3cm, 15.6cm, 14.4cm, and the mass ratios are 3%, 33%, 1200Kg of 32.5%, 16%, and 15.5% ground baseballs are added to the 300L tiltable wet mill manufactured by Hunan Xiangtan Gaosheng Powder Equipment Co., Ltd.

[0047] (2) Select tungsten carbide with a particle size of 0.9 μm and 4.5 μm, spherical cobalt powder of 1.0 μm, and chromium carbide of 1.0 μm according to the mass ratio of 56:24:19.3:0.7 to form a 300Kg raw material input step (1) The wet mill is used for mixing.

[0048] (3) Ethanol with a concentration ≥ 98% is directly added to the wet mill described in step (2) as a grinding medium, and the volume of ethanol is 66L.

[0049] (4) Wet grinding the mixed material processed through the above steps.

[0050] (5) Sele...

Embodiment 2

[0056] Such as figure 1 Shown, a kind of preparation method of cemented carbide cutting tool material, comprises the steps:

[0057] (1) Use 1200Kg of grinding baseballs with a diameter of 5.5cm and a height of 14.4cm, and add them to the 300L tiltable wet mill manufactured by Hunan Xiangtan Gaosheng Powder Equipment Co., Ltd.

[0058] (2) select particle size as tungsten carbide of 0.6 μm and 3 μm, spherical cobalt powder of 1.0 μm, and chromium carbide of 1.0 μm according to the ratio of mass ratio of 64:16:19.3:0.7 to be made into 300Kg raw material input step (1) The wet mill described above was used for mixing.

[0059] (3) Ethanol with a concentration ≥ 98% is directly added to the wet mill described in step (2) as a grinding medium, and the volume of ethanol is 66L.

[0060] (4) Wet grinding the mixed material processed through the above steps.

[0061] (5) Select a 400-mesh stainless steel screen to sieve the wet abrasive slurry.

[0062] (6) Put the slurry process...

Embodiment 3

[0067] Such as figure 1 Shown, a kind of preparation method of cemented carbide cutting tool material, comprises the steps:

[0068] (1) Use 1300Kg of grinding baseballs with a diameter of 7.3cm and a height of 15.6cm, and add them to the 300L tiltable wet mill manufactured by Hunan Xiangtan Gaosheng Powder Equipment Co., Ltd.

[0069] (2) Select tungsten carbide with particle size of 0.7 μm and 3.5 μm, spherical cobalt powder of 1.5 μm, and chromium carbide of 1.5 μm according to the mass ratio of 76.5:8.5:14.5:0.5 to make 300Kg of raw materials into step (1) The wet mill is used for mixing.

[0070] (3) Ethanol with a concentration ≥ 98% is directly added to the wet mill described in step (2) as a grinding medium, and the volume of ethanol is 72L.

[0071] (4) Wet grinding the mixed material processed through the above steps.

[0072] (5) Select a 400-mesh stainless steel screen to sieve the wet abrasive slurry.

[0073] (6) Put the slurry processed in step (5) into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com