Method and device for passive fire extinguishing of liquid carbon dioxide in underground coal mine

A technology of liquid carbon dioxide and fire extinguishing device, which is applied to the method of container discharge, the installation device of container structure, fire prevention and other directions, can solve the problems of lag in fire prevention and extinguishing measures, prone to fire, monitoring and prevention difficulties, etc., to overcome the time lag. , low cost, good effect of promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

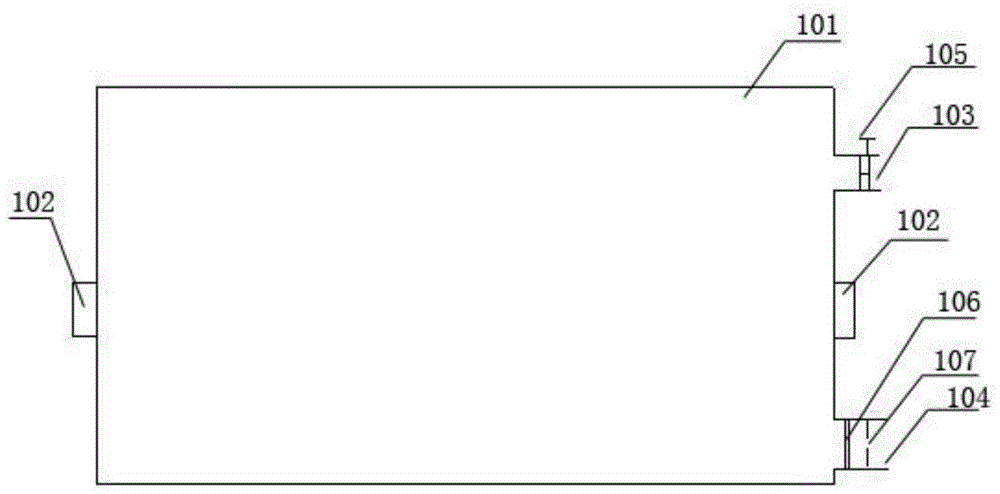

Embodiment 1

[0030] Vacuumize the tank body of the above-mentioned device of the present invention, and the vacuum degree is 5KPa, then inject sulfur hexafluoride gas from the liquid carbon dioxide injection port, and then inject liquid carbon dioxide (temperature -18~-20°C), sulfur hexafluoride gas and liquid The volume ratio of carbon dioxide is 0.5:1000, and the internal pressure of the tank after filling is 2MPa, then close the cryogenic ball valve at the injection port of liquid carbon dioxide. The above-mentioned device filled with liquid carbon dioxide is placed anywhere behind the working face of the mine, in the goaf or blind alley of the coal mine, or the device of the present invention is placed in the area where the threat of fire is considered to be high. For example, the device of the present invention is pre-placed in the goaf, and can be put into the goaf from the upper corner or the lower corner, and then tied to the handling handle with a steel wire rope, and the device of...

Embodiment 2

[0032] Vacuumize the tank body of the above-mentioned device of the present invention, and the vacuum degree is 9KPa, then inject sulfur hexafluoride gas from the liquid carbon dioxide injection port, and then inject liquid carbon dioxide (temperature -18~-20°C), sulfur hexafluoride gas and liquid The volume ratio of carbon dioxide is 1:1000, the internal pressure of the tank after filling is 3MPa, and then close the cryogenic ball valve at the injection port of liquid carbon dioxide. The above-mentioned device filled with liquid carbon dioxide is placed anywhere behind the working face of the mine, in the goaf or blind alley of the coal mine, or the device of the present invention is placed in the area where the threat of fire is considered to be high. Blind alley is a closed roadway, and people cannot go inside, and the coal inside may also be natural. Steel wire ropes can be used to be tied on the carrying handle, and the device of the present invention can be pulled to a su...

Embodiment 3

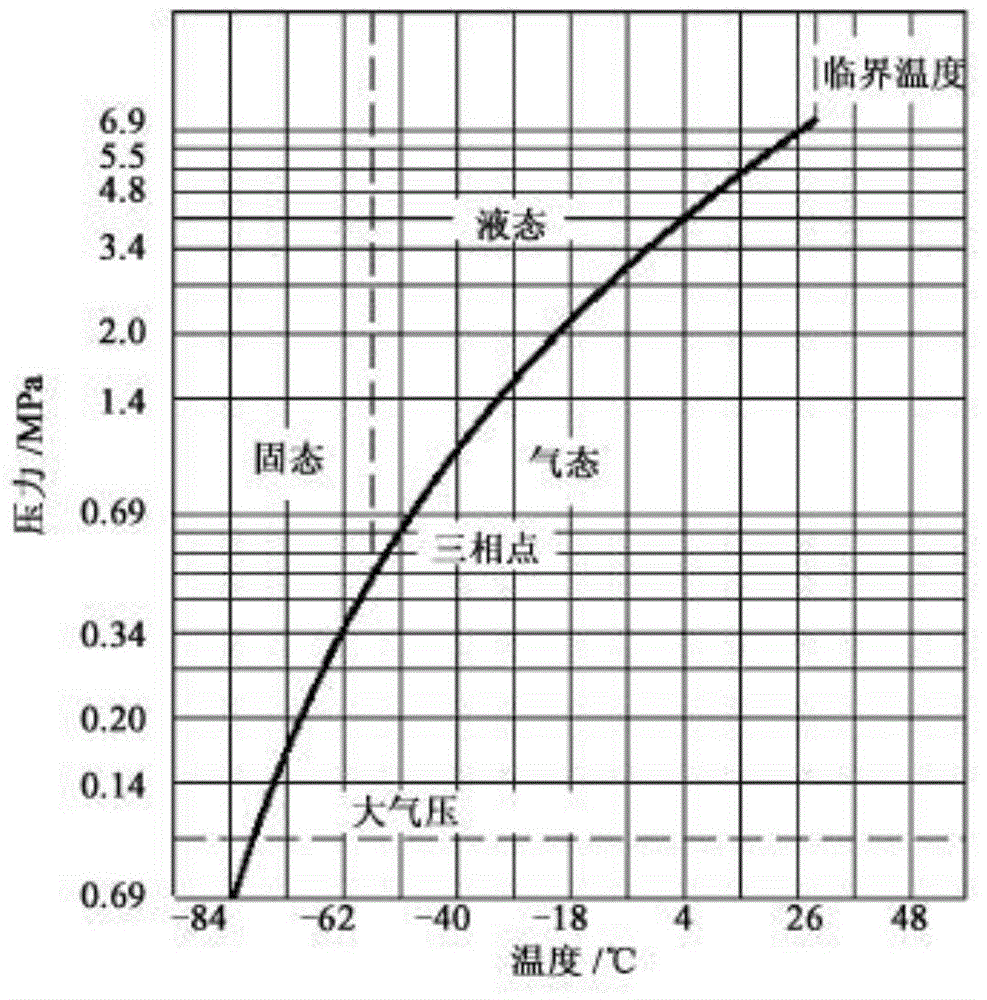

[0034] Vacuumize the tank body of the above-mentioned device of the present invention, and the vacuum degree is 10KPa, then inject sulfur hexafluoride gas from the liquid carbon dioxide injection port, and then inject liquid carbon dioxide (temperature -18~-20°C), sulfur hexafluoride gas and liquid The volume ratio of carbon dioxide is 0.8:1000, the internal pressure of the tank after filling is 2.5MPa, and then close the cryogenic ball valve at the injection port of liquid carbon dioxide. The above-mentioned device filled with liquid carbon dioxide is placed anywhere behind the working face of the mine. Along with the advancing of working face, above-mentioned device just is farther and farther away from working face. When the residual coal and oxygen in the goaf undergo a chemical reaction and the heat generated is greater than the heat taken away by the wind, the temperature of the coal body rises. When the ambient temperature is higher than 31°C (the normal temperature in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com