A method for anti-corrosion treatment of tail rudder connecting rod thread

A technology of anti-corrosion treatment and threading, which is applied to threaded fasteners, pre-treated surfaces, nuts, etc., can solve problems such as relatively small requirements, limited service life and reliability, and no means of solution, and achieve simple and easy-to-control operation steps , anti-corrosion environment-friendly, reliable process principle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

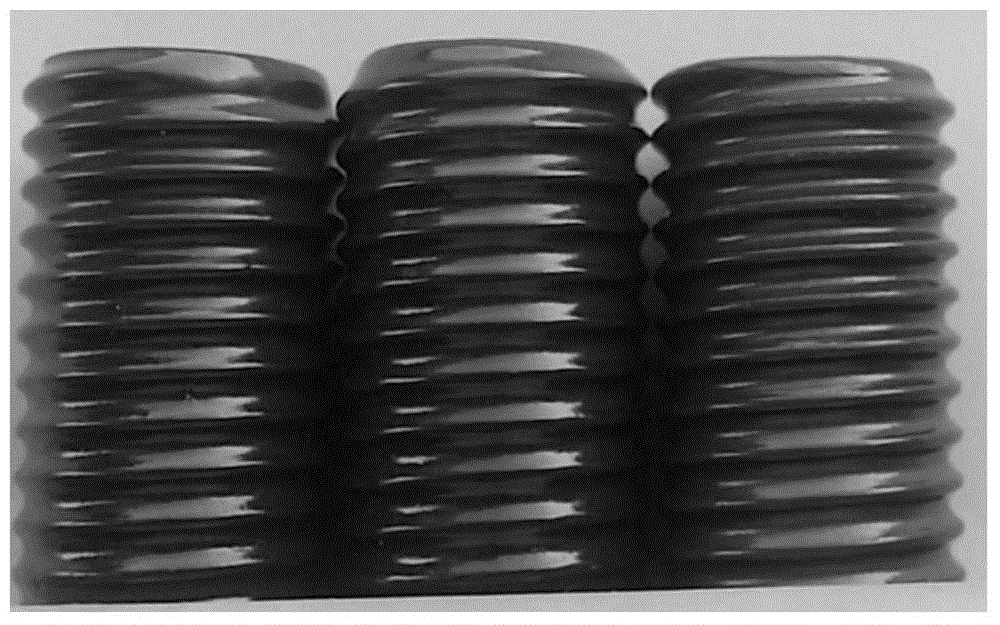

[0019] In this embodiment, the thread of the tail rudder connecting rod is first sandblasted to Sa2.5 level at the position to be sprayed, and the dust is cleaned for use; the first sintering parameters: the electrostatic powder feeding nozzle is 400mm away from the workpiece, the voltage is 40kV, and the uniform PEEK powder is 140~ After 160um, put it into an oven preheated to 240-260°C, quickly raise the temperature to 420°C and keep it for 10 minutes, open the oven insulation door, take it out after cooling for 5 minutes, and naturally cool it to room temperature in the air; the second sintering parameter: electrostatic The powder feeding nozzle is 400mm away from the workpiece, and the voltage is 60kV. After depositing uniform PEEK powder of 140-160um, put it into an oven preheated to 240-260°C; quickly heat up to 420°C and keep it for 15 minutes, open the oven insulation door, and cool for 5 minutes Then take it out and cool it naturally in the air to normal temperature. T...

Embodiment 2

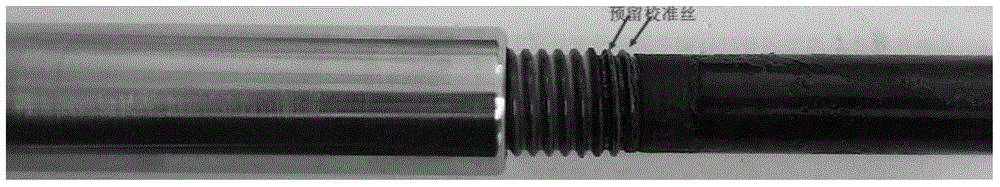

[0021] In this embodiment, a 150um tolerance is reserved for the male thread and female thread of the rudder connecting rod thread used, and then the thread is sandblasted to Sa2.5 level at the position to be sprayed, and the dust is cleaned for use; figure 2 The reserved calibration wire in the cover is covered, the electrostatic powder feeding nozzle is 400mm away from the workpiece, the voltage is 50kV, and a powder coating with a uniform thickness of about 480-520um is deposited, and then placed in an oven preheated to 240-260°C, and the temperature is quickly raised to 420°C Keep it for 15 minutes, then open the oven insulation door, take it out after cooling for 5 minutes, and cool it to room temperature in the air, then use the first thread of the reserved tail rudder connecting rod thread as a reference, and use a feed rate of 10~ 25um turning method, the coating on the thread is turned to 300um, then put it into the oven to quickly heat up to 380°C and keep it for 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com