Array substrate doping method and doping equipment

An array substrate and substrate technology, applied in the field of substrate manufacturing, can solve the problems of complex doping process, process error, increased cost and production cycle, etc., and achieve the effect of simplifying process and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

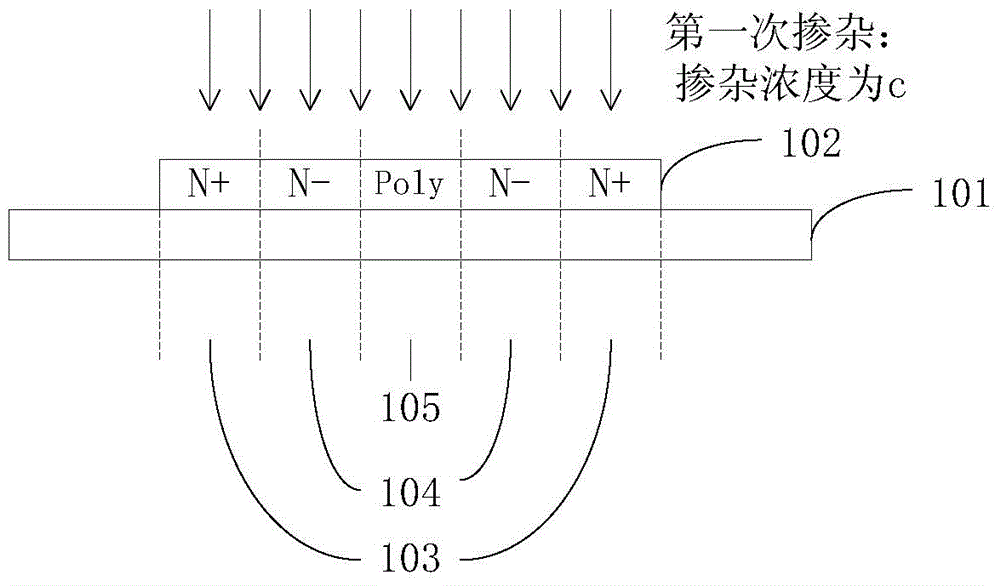

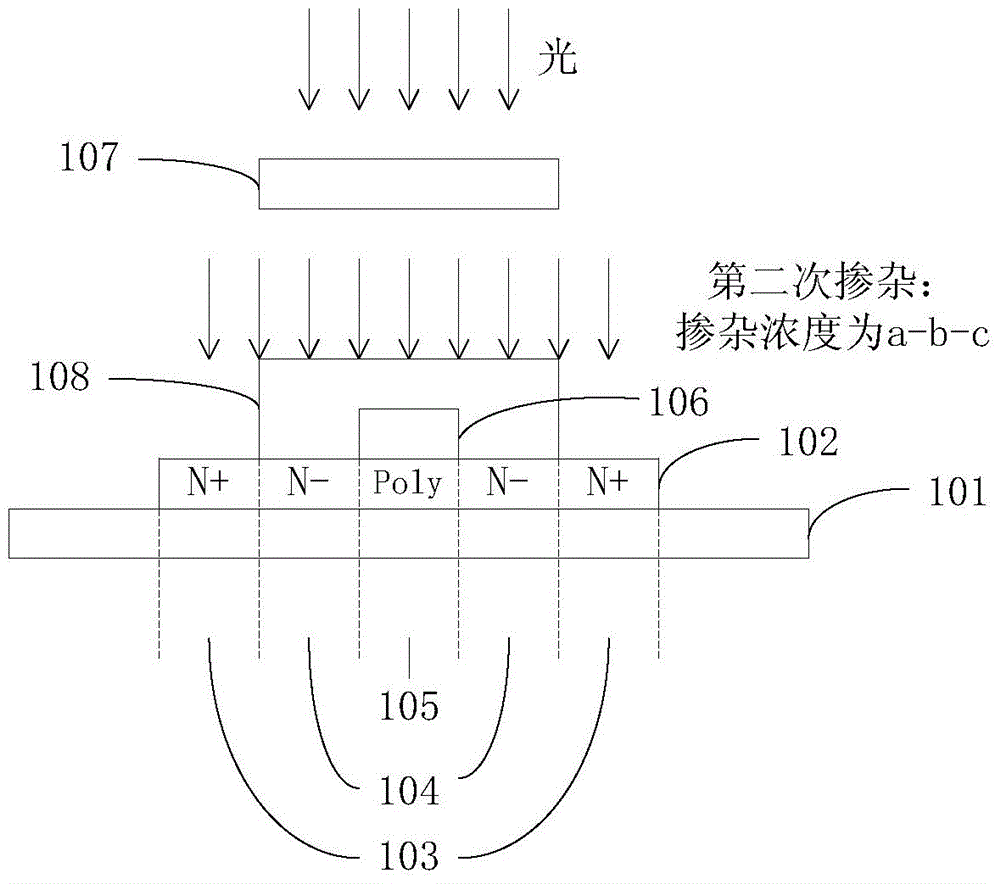

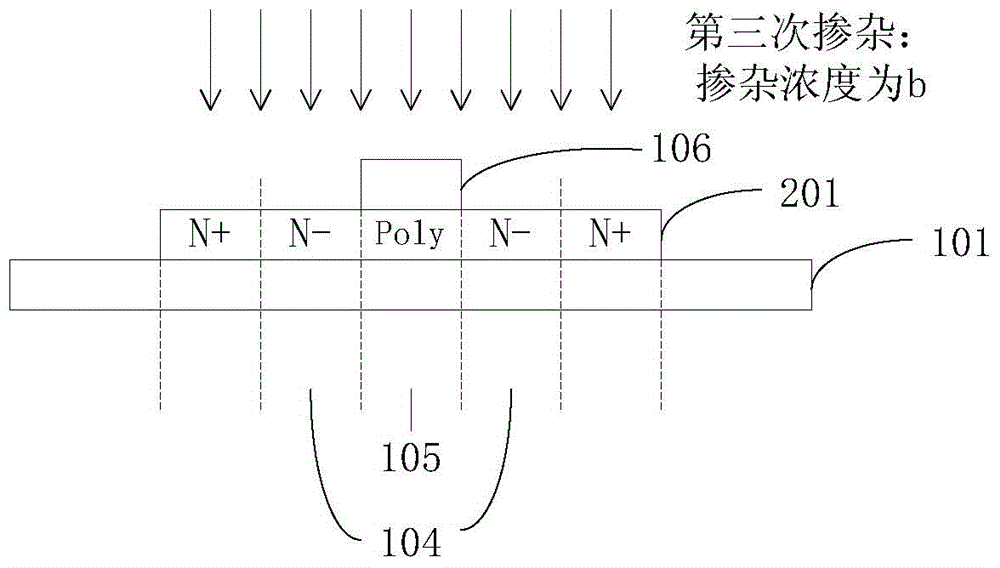

[0029] see figure 2 and image 3 , figure 2 is a schematic flow chart of the first embodiment of the doping method of the array substrate of the present invention, image 3 yes figure 2 The process schematic diagram corresponding to the first embodiment of the doping method shown, this embodiment provides a doping method, including steps:

[0030] S201: Provide a substrate, on which a region to be heavily doped, a region to be lightly doped, and a channel region to be doped are defined.

[0031] Generally speaking, processing holes, electroplating, etching, and arranging electronic components on the substrate 301 can realize electrical, magnetic, or optical functions. Doping a small amount of other elements or compounds in the substrate 301 can make the substrate 301 produce specific properties. Specifically, for example, doping phosphorus P or gallium Ga in a semiconductor silicon substrate can obtain n-type or p-type semiconductor materials respectively; in the inorg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com