Biological-compatibility artificial ear and in-vitro rapid construction method thereof

A biocompatible, artificial ear technology, applied in the direction of prosthesis, medical science, etc., can solve the problems of high cost of plastic surgery and low biocompatibility of artificial ear, and achieve the effect of reducing biological toxicity and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

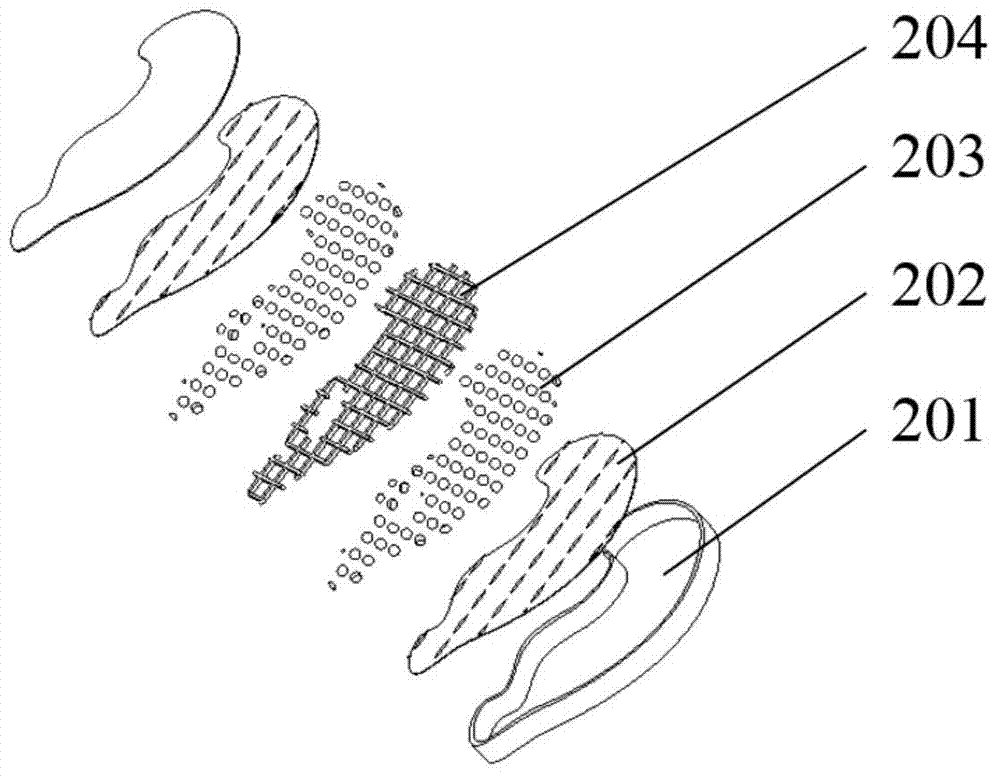

[0065] Example 1: A biocompatible artificial ear was fabricated by multi-nozzle three-dimensional printing.

[0066] a) Designing the digital three-dimensional model of the artificial ear by a computer, and assigning a print forming path by the computer, and controlling the operation of the three-dimensional printing device;

[0067] b) Mix the prepared sodium alginate with a mass volume concentration of 2% and 20% gelatin to obtain a natural polymer sodium alginate / gelatin hydrogel, mix the chondrocytes with the hydrogel, and mix the The concentration of chondrocytes was 10 8 each / mL; the hydrogel containing chondrocytes was loaded into the extrusion nozzle assembly of the composite multi-nozzle 3D printing equipment; using the microcapsule preparation process, the hydrogel containing adipose-derived stem cells and endothelial cell growth factor with a particle size of 100 μm was obtained Gel microcapsules, the microcapsules were suspended in phosphate buffered saline (PBS),...

Embodiment 2

[0075] Example 2: A biocompatible artificial ear was prepared by using multi-nozzle three-dimensional printing.

[0076] a) Designing the digital three-dimensional model of the artificial ear by a computer, and assigning a print forming path by the computer, and controlling the operation of the three-dimensional printing device;

[0077] b) Mix the prepared sodium alginate with a mass volume concentration of 3% and 15% gelatin to obtain a natural polymer hydrogel, and combine chondrocytes, adipose stem cells, and Schwann cells with the hydrogel respectively Mix, the mixed chondrocyte density is 10 7 cells / mL, the density of adipose-derived stem cells was 10 4 cells / mL, the Schwann cell density was 10 6 each / mL; the cell-containing hydrogel is loaded into the extrusion nozzle assembly of the composite multi-nozzle 3D printing device; using the microcapsule preparation process, the 1% fibrinogen hydrogel of endothelial cell growth factor with a particle size of 20 μm is obtain...

Embodiment 3

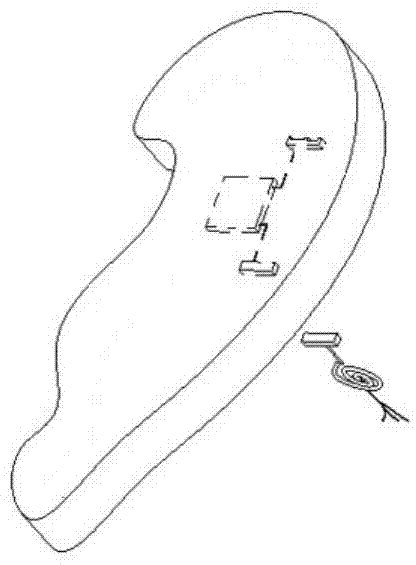

[0084] Example 3: A biocompatible artificial ear embedded with a cochlear implant was fabricated by multi-nozzle three-dimensional printing.

[0085] a) The digital three-dimensional model is obtained by CT scanning the external ear pinna of normal human body, which is used as the contour design of the artificial ear, and the computer assigns the printing forming path to control the operation of the three-dimensional printing equipment;

[0086] b) The prepared fibrinogen with a mass volume concentration of 1% and collagen 5% is used to obtain a natural polymer hydrogel, and the cartilage stem cells are mixed with the hydrogel, and the concentration of the mixed cartilage stem cells is 10 5 each / mL; the hydrogel containing cartilage stem cells was loaded into the extrusion nozzle assembly of the composite multi-nozzle 3D printing equipment; the microcapsule preparation process was used to obtain the hydrogel microcapsules containing nerve cell growth factor with a particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com