Preparation method of adsorbent for adsorbing low-density lipoprotein (LDL) for whole blood perfusion

A low-density lipoprotein and adsorbent technology, which is applied in the fields of polymer chemistry and biomedicine, can solve the problems of the limitation of ligand immobilization, affecting the adsorption effect of the adsorbent on the target substance, and the limited removal effect, and achieves excellent adsorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

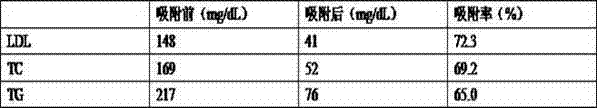

Embodiment 1

[0043] Preparation of the adsorbent for adsorbing low-density lipoprotein for whole blood perfusion:

[0044] Synthesis of Macroporous Polystyrene Adsorbent Resin:

[0045] Add 600mL of aqueous solution containing 0.5wt% polyvinyl alcohol and 3wt% NaCl to a 1000mL three-necked flask, add 25g styrene, 25g divinylbenzene (DVB) with a purity of 63wt%, 25g toluene, 35g 200 # The mixed organic phase of gasoline and 0.5g benzoyl peroxide (BPO) was heated to 75°C for 5 hours under mechanical stirring, and then heated to 80°C for overnight reaction. After the reaction was completed, it was cooled, extracted with acetone for 12 hours, and washed with water until There is no acetone smell, suction filtration, drying, sieving, and selecting the resin with a particle size of 0.6-1.2mm to obtain the required macroporous polystyrene adsorption resin. The specific surface area (BET) of the obtained macroporous polystyrene adsorption resin is 343m 2 / g, the pore volume is 0.79cm 3 / g, the ...

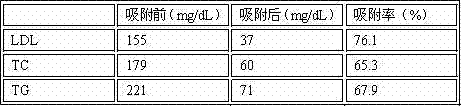

Embodiment 2

[0060] Preparation of the adsorbent for adsorbing low-density lipoprotein for whole blood perfusion:

[0061] Synthesis of Macroporous Polystyrene Adsorbent Resin:

[0062] Add 600mL of aqueous solution containing 0.5wt% polyvinyl alcohol and 3wt% NaCl to a 1000mL three-necked flask, add 5g styrene, 45g divinylbenzene (DVB) with a purity of 63wt%, 50g toluene, 30g n-heptane, 0.5 g Mixed organic phase of benzoyl peroxide (BPO), under mechanical stirring, heat up to 75°C for 5 hours, then heat up to 80°C for overnight reaction, after the reaction, cool down, extract with acetone for 12 hours, wash with water until there is no acetone smell , suction filtration, and drying to obtain a macroporous polystyrene adsorption resin; select the resin with a particle size of 0.6 to 1.2mm, and the specific surface area (BET) of the obtained macroporous polystyrene adsorption resin is 415m 2 / g, the pore volume is 1.02cm 3 / g, the average pore diameter is 9.83nm.

[0063] After synthesiz...

Embodiment 3

[0077] Preparation of the adsorbent for adsorbing low-density lipoprotein for whole blood perfusion:

[0078] Synthesis of Macroporous Polystyrene Adsorbent Resin:

[0079] Add 500mL aqueous solution containing 0.5wt% polyvinyl alcohol and 3wt% NaCl to a 1000mL three-necked flask, add 25g styrene, 10g divinylbenzene (DVB) with a purity of 63wt%, 21g toluene, 21g n-heptane, 0.35 g Mixed organic phase of benzoyl peroxide (BPO), under mechanical stirring, heat up to 75°C for 5 hours, then heat up to 80°C for overnight reaction, after the reaction, cool down, extract with acetone for 12 hours, wash with water until there is no acetone smell , suction filtration, and drying to obtain a macroporous polystyrene adsorption resin; select resins with a particle size of 0.6 to 1.2mm, and the specific surface area (BET) of the obtained macroporous polystyrene adsorption resin is 165m 2 / g, the pore volume is 0.67cm 3 / g, the average pore diameter is 16.24nm.

[0080] After synthesizing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com