Water vapor generation method and device with control of flow quantity

A water vapor generation and flow control technology, applied in chemical instruments and methods, water, inorganic chemistry, etc., can solve the problems of unstable water vapor and low precision of water vapor flow control, and achieve stable generation, improved control accuracy, and high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

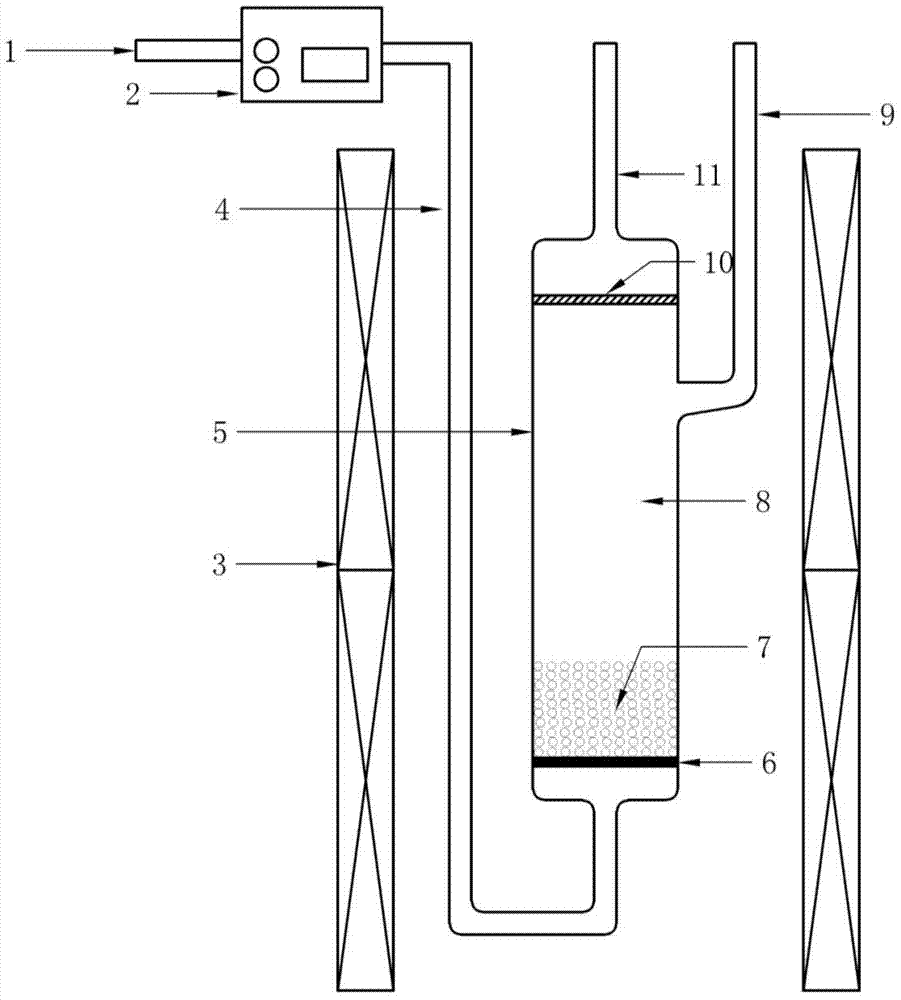

[0034] figure 1Shown is the structural representation of the present invention based on fluidized bed reactor water vapor generating device, and described fluidized bed reactor is micro fluidized bed reactor, and the diameter of this fluidized bed reactor is 60mm, height 180mm, fluidized bed The use of quartz material for the reactor ensures that the fluidized bed reactor itself does not react with hydrogen and / or water vapor. The air distribution plate 6 in the fluidized bed reactor ensures that the gas passes from bottom to top, and the copper oxide particles 7 will not leak from the reaction chamber 8 to the preheating pipeline 5; the height of the bed of copper oxide particles 7 ensures that the gas is in the bed The residence time of hydrogen is longer than the time required for the complete reaction of hydrogen; the gas-solid separation plate 10 ensures that the gas passes from bottom to top, and the copper oxide particles 7 will not escape from the reaction chamber 8 to...

Embodiment 2

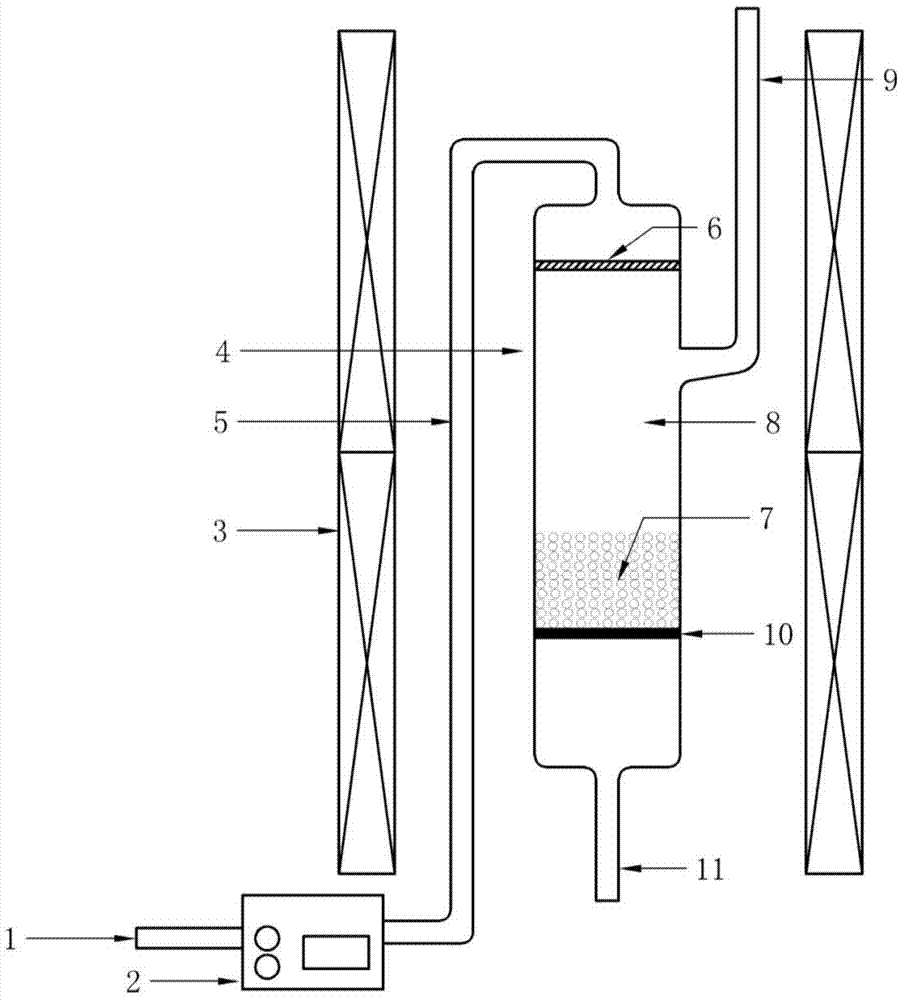

[0038] figure 2 Shown is the structural representation of the water vapor generating device based on the fixed bed reactor of the present invention, the fixed bed reactor is a miniature fixed bed reactor, the diameter of the fixed bed reactor is 60mm, the height is 180mm, and the fixed bed reactor uses quartz material , to ensure that the fixed bed reactor itself does not react with hydrogen and / or water vapor. The air distribution plate 6 in the fixed-bed reactor ensures that the gas passes from top to bottom; the height of the bed of copper oxide particles 7 ensures that the residence time of the gas in the bed is greater than the time required for the complete reaction of hydrogen; the gas-solid separation plate 10 ensures that the gas passes through Pass up and down, and the copper oxide particles 7 will not escape from the reaction chamber 8 to the water vapor output pipe 11 .

[0039] The method for generating 0.001 mol / min water vapor with the above-mentioned device i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com