A kind of preparation method of nano flake zinc phosphate

A nano-flaky, zinc phosphate technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem that protective coatings are difficult to overcome harsh conditions, and achieve economical cost savings, obvious lamellar structure, source of wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

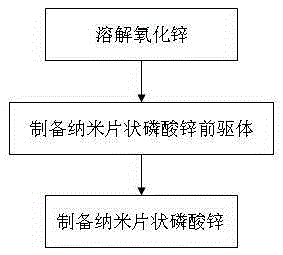

[0028] The specific embodiment of the present invention is as figure 1 As shown, the steps are as follows:

[0029] Weigh 20g of deionized water and add it to a 100mL beaker, then add 1.5g of ammonium carbonate and 15.0g of 25% ammonia water to the beaker, and stir with a magnetic stirrer to completely dissolve the ammonium carbonate to prepare a compound solution.

[0030] Weigh 1.0g of zinc oxide, add it to the beaker of the compound solution, then weigh 0.2g polyethylene glycol-2000 dispersant, add it to the beaker of the compound solution, and carry out ultrasonic dissolution for 30min, stirring continuously during the ultrasonic process, It was completely dissolved into a colorless transparent solution.

[0031] Put the 100mL beaker containing the colorless and transparent solution into a water bath at 70-75°C, and stir at a speed of 300r / min until the colorless and transparent solution becomes slightly cloudy, then immediately take out the 100mL beaker and pour it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com