A method for purifying carbon nanotubes by evaporating acid

A carbon nanotube, multi-wall carbon nanotube technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of destroying the surface structure of carbon nanotubes, reducing the performance of carbon nanotubes, commercial problems such as low value, to achieve the effect of simple process, difficult removal of impurities, and reduction of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

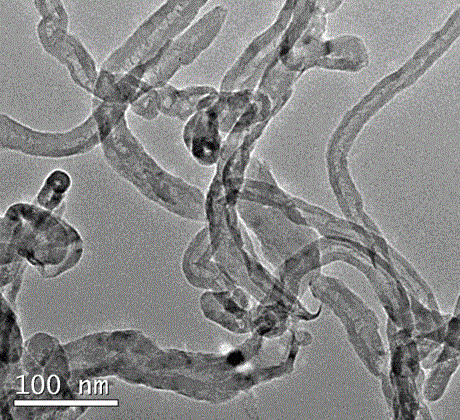

[0025] Purification of multi-walled carbon nanotubes by evaporating concentrated nitric acid:

[0026] Put 0.3g of original multi-wall carbon nanotubes (prepared by chemical vapor deposition) into a sand core funnel with a pore size of 20-30 microns, and place the sand core funnel with original multi-wall carbon nanotubes in a volume of 50 ml In a Teflon container, 3ml of concentrated nitric acid is placed at the bottom of the Teflon container. Put the Teflon container into a reaction kettle with a volume of 100ml, and seal it. Put it into the drying box again, the temperature of the drying box is 200° C., and the duration is 5 hours. Take out the reaction kettle to cool to room temperature, open the reaction kettle and take out the sand core funnel, put the carbon nanotubes into a clean beaker, dilute with 100ml of distilled water, pour the diluted carbon nanotubes into a 10 cm diameter beaker with ordinary filter paper In the Buchner funnel, wash with water and absolute et...

Embodiment 2

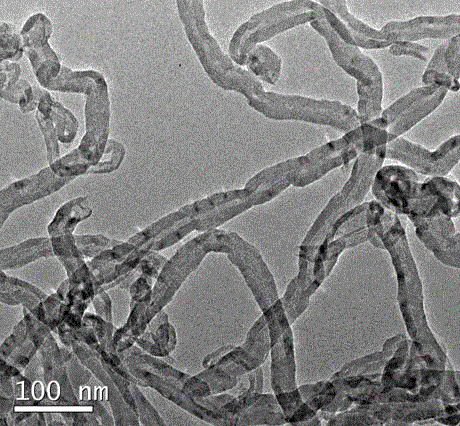

[0028] Purification of multi-walled carbon nanotubes by evaporating concentrated sulfuric acid:

[0029] Put 0.1g of original multi-walled carbon nanotubes (prepared by chemical vapor deposition method) into a sand core funnel with a pore size of 20-30 microns, and place the sand core funnel with the original multi-walled carbon nanotubes in a volume of 50 ml Put 1ml of concentrated nitric acid into the bottom of the Teflon container. Put the Teflon container into a reaction kettle with a volume of 100ml, and seal it. Put it into the drying box again, the temperature of the drying box is 180° C., and the duration is 4 hours. Take out the reaction kettle to cool to room temperature, open the reaction kettle and take out the sand core funnel, put the carbon nanotubes into a clean beaker, dilute with 50ml of distilled water, pour the diluted carbon nanotubes into a 10 cm diameter beaker with ordinary filter paper In the Buchner funnel, wash with water and absolute ethanol 10 ti...

Embodiment 3

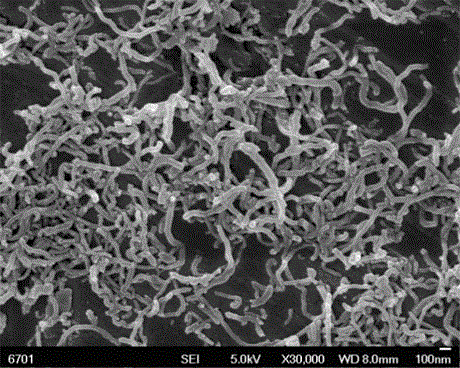

[0031] Evaporation of mixed acid (volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1) to purify multi-walled carbon nanotubes:

[0032] Put 0.4g of original multi-walled carbon nanotubes (prepared by chemical vapor deposition method) into a sand core funnel with a pore size of 10-20 microns, and place the sand core funnel with the original multi-walled carbon nanotubes in a volume of 50 ml Put 4ml of mixed acid (concentrated sulfuric acid 3ml, concentrated nitric acid 1ml) into the bottom of the Teflon container. Put the Teflon container into a reaction kettle with a volume of 100ml, and seal it. Put it into the drying box again, the temperature of the drying box is 150 ℃, and the duration is 4 hours. Take out the reaction kettle to cool to room temperature, open the reaction kettle and take out the sand core funnel, put the carbon nanotubes into a clean beaker, dilute with 40ml of distilled water, pour the diluted carbon nanotubes into a 10 cm dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com