Magnesium phosphate cement as well as preparation method and application thereof

A technology of magnesium phosphate bone cement and phosphate, which is applied in the field of medical biological materials, can solve the problems of fast hydration reaction speed, decreased human function, obvious side effects, etc., and achieves reduction of hydration reaction speed, lower hydration temperature, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

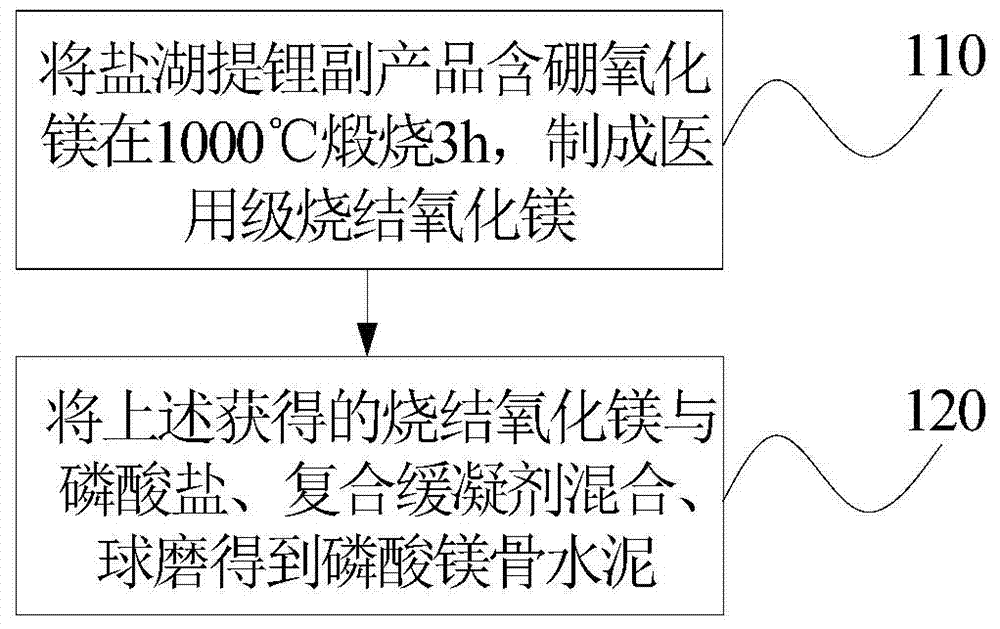

[0024] figure 1 It is a flowchart of the preparation method of the magnesium phosphate bone cement according to the embodiment of the present invention.

[0025] refer to figure 1 , the preparation method of the magnesium phosphate bone cement according to the embodiment of the present invention comprises steps:

[0026] Step 110: Calcining boron-containing magnesia, a by-product of lithium extraction from salt lake, at 1000° C. for 3 hours to produce medical grade sintered magnesia. Wherein, the sintered magnesia of this embodiment refers to: the magnesia slag rich in magnesia (that is, the boron-containing magnesia by-product of lithium extraction from salt lake in this embodiment) is calcined at a high temperature, and all or part of the magnesia components therein are transformed into For magnesium oxide crystals. The magnesium oxide crystal has certain activity, and the presence of the active magnesium oxide helps the magnesium phosphate bone cement to form a skeleton ...

Embodiment 2

[0041] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between Example 2 and Example 1 is that: in step 110, sintered magnesia is obtained by calcining at a calcination temperature of 800° C. for 3 h; in step 120, the amount of sintered magnesia is 200 parts, and ammonium dihydrogen phosphate is 100 parts were ball milled for 30 minutes to obtain magnesium phosphate bone cement powder with a particle size of about 10 μm. The amount of composite retarder is 20 parts, which is 10% of the amount of sintered magnesia, wherein the mass fractions of glucose, sucrose, citric acid and chloride in each composite retarder are 25%, 25%, and 10% respectively , 40%; In the present embodiment, the chloride is sodium chloride, but the present invention is not limited thereto, other chlorides with similar properties can be used.

Embodiment 3

[0052] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between Example 3 and Example 1 is that: in step 110, sintered magnesia is obtained by calcining at a calcination temperature of 1400° C. for 6 h; in step 220, the amount of sintered magnesia is 400 parts, and sodium dihydrogen phosphate is 100 parts, ball milled for 10 minutes to obtain magnesium phosphate bone cement powder with a particle size of about 70 μm; the amount of composite retarder is 60 parts, which is 15% of the amount of sintered magnesium oxide, wherein, in each part of composite retarder, sucrose and chlorine The mass fraction of sodium chloride is 50%.

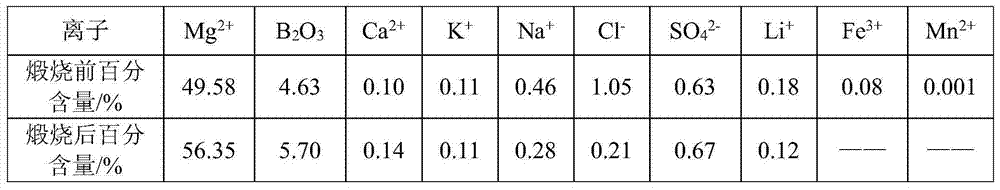

[0053] The mass fractions of the ions in boron-containing magnesium oxide, a by-product of lithium extraction from salt lakes, were analyzed before and after calcination, and the results are shown in Table 6.

[0054] Table 6

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com