Soft-magnetic magnetostrictive ferrite material and manufacturing method thereof

A ferrite material and magnetostriction technology, applied in the field of magnetic materials, to achieve the effect of both market competitiveness, high reliability, and negative magnetostriction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

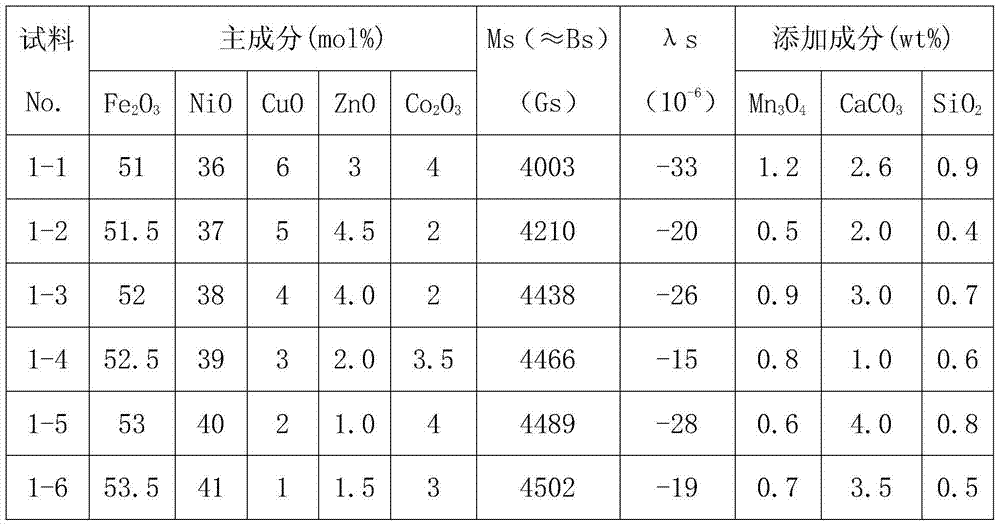

[0022] Proportion the main components and additives in specified amounts as shown in Table 1.

[0023] The preparation method is:

[0024] (1) Primary ball milling: the main components are mixed according to the ratio, and the obtained mixture is wet-processed primary ball milling, and the average particle size of the granular material after the primary ball milling is 0.8-1.5 μm.

[0025] (2) Pre-burning: Pre-burning the pellets after primary ball milling in the air, the pre-burning temperature is controlled at 1050° C., and kept for 4 hours.

[0026] (3) Secondary ball milling: perform wet secondary ball milling on the calcined granules together with the additives, and the average particle size of the granules after the secondary ball milling is 0.8-1.2 μm.

[0027] (4) Molding and sintering: dry the granules after secondary ball milling, add a polyvinyl alcohol solution with a concentration of 12% of 11wt% of pre-fired material, mix evenly, spray granulate, and press to fo...

Embodiment 2

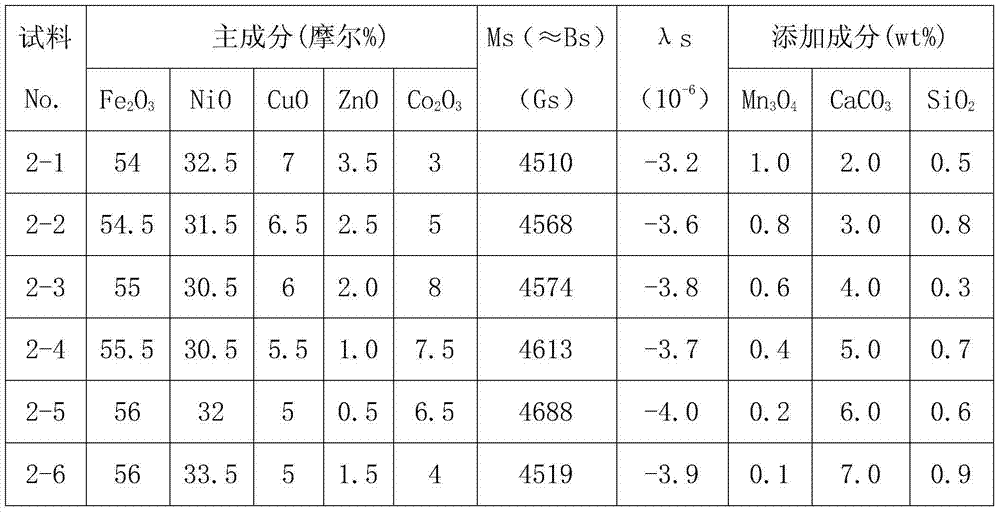

[0038] The main components and additives are proportioned according to the specified amounts shown in Table 2.

[0039] The preparation method is:

[0040] (1) Primary ball milling: the main components are mixed according to the ratio, and the obtained mixture is wet-processed primary ball milling, and the average particle size of the granular material after the primary ball milling is 0.8-1.5 μm.

[0041] (2) Pre-burning: Pre-burn the pellets after primary ball milling in the air, the pre-burning temperature is controlled at 1050° C., and the temperature is kept for 0.5 hours.

[0042] (3) Secondary ball milling: perform wet secondary ball milling on the calcined granules together with the additives, and the average particle size of the granules after the secondary ball milling is 0.8-1.2 μm.

[0043] (4) Molding and sintering: dry the granules after the secondary ball milling, add a polyvinyl alcohol solution with a concentration of 10wt% of 13wt% of the weight of the pre-fir...

Embodiment 3

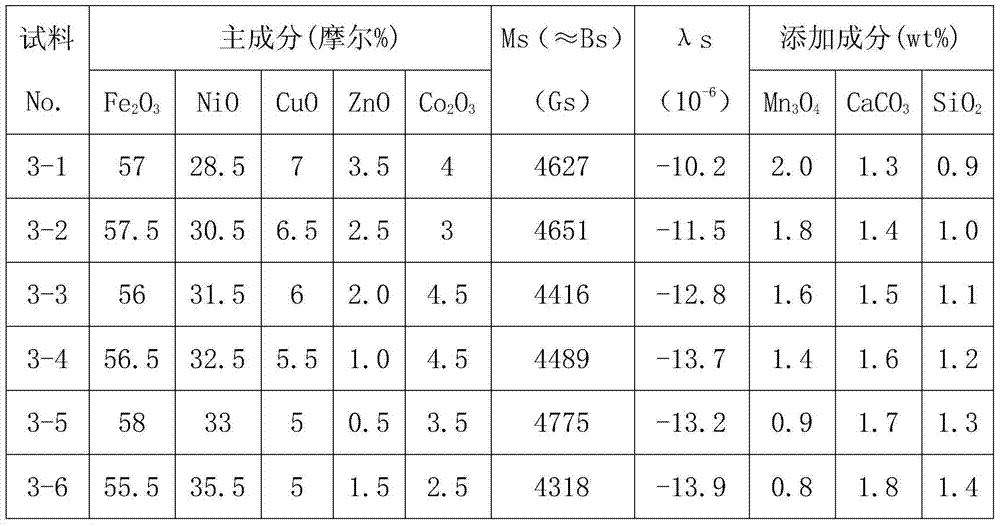

[0054] The main components and additives were mixed in predetermined amounts as shown in Table 3.

[0055] The preparation method is:

[0056] (1) Primary ball milling: the main components are mixed according to the ratio, and the obtained mixture is wet-processed primary ball milling, and the average particle size of the granular material after the primary ball milling is 0.8-1.5 μm.

[0057] (2) Pre-burning: Pre-burn the pellets after primary ball milling in the air, the pre-burning temperature is controlled at 1110° C., and the temperature is kept for 2.5 hours.

[0058] (3) Secondary ball milling: perform wet secondary ball milling on the calcined granules together with the auxiliary components, and the average particle size of the granules after the secondary ball milling is 0.8-1.2 μm.

[0059] (4) Molding and sintering: dry the granules after secondary ball milling, add a polyvinyl alcohol solution with a concentration of 12wt% of the weight of pre-sintered material, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com