A method for separating sec-butyl acetate from the mixture after the reaction of acetic acid and C4

A technology for sec-butyl acetate and mixtures, applied in the field of separation of unreacted C4, can solve the problems of separation tower operating pressure and separation efficiency, material loss and separation energy consumption, etc., to reduce the possibility of acid on the top of the tower and reduce heating Requirements for heat source, effect of lowering tower top temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

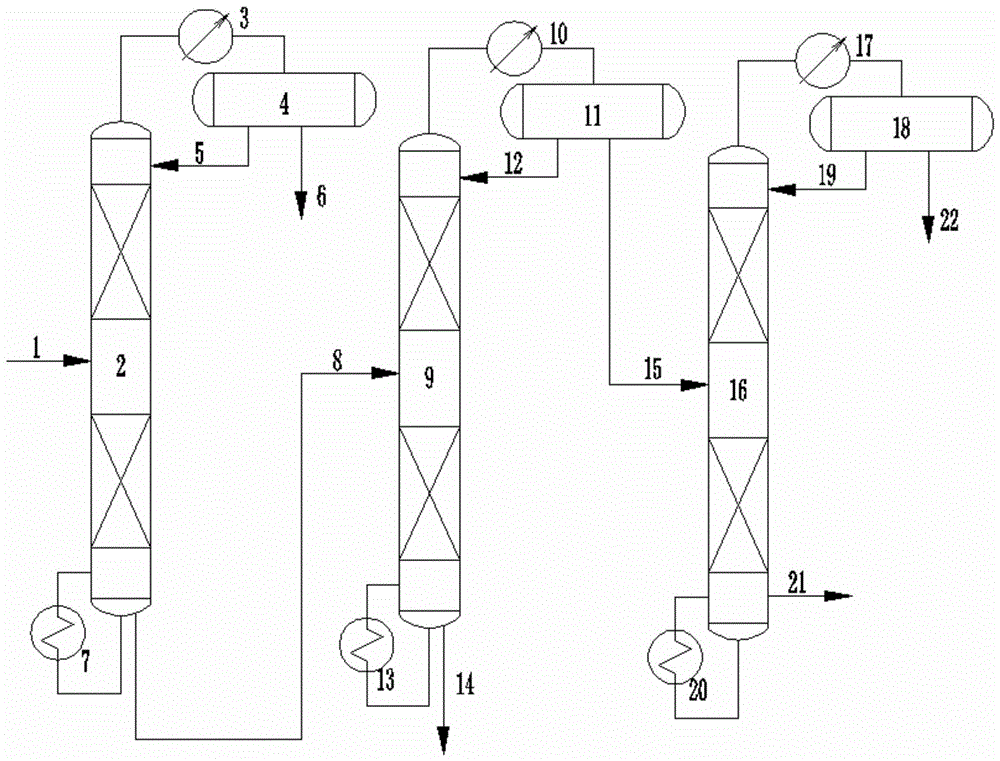

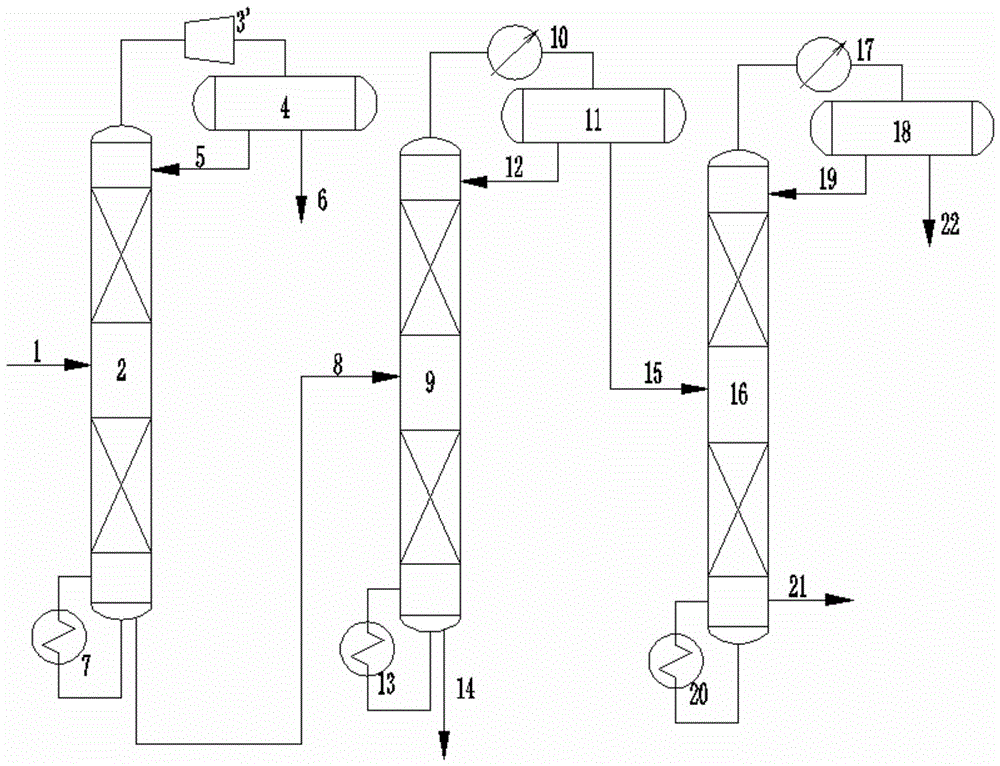

Method used

Image

Examples

Embodiment 1

[0041] The reaction mixture of acetic acid and C4 containing acetic acid, sec-butyl acetate, C4 and C8 hydrocarbons is sent into the de-light component tower at a speed of 10t / h, wherein the content of acetic acid is 6.54wt%, and the content of sec-butyl acetate The content of C4 is 79.62wt%, the content of C4 is 5.57wt%, and the content of C8 hydrocarbon is 8.27wt%. C4 is used as the reflux at the top of the tower, and the other part is extracted as the product. Acetic acid, sec-butyl acetate and C8 hydrocarbons fall into the bottom of the tower, and are sent to the azeotropic distillation column after being extracted from the tower kettle. The operating conditions of the light component removal tower It is: the temperature at the top of the tower is -30°C, the temperature at the bottom of the tower is 100°C, the pressure is normal pressure, the reflux ratio is 20, and the number of theoretical plates is 10; Tower, sec-butyl acetate, water, and C8 hydrocarbons are evaporated ...

Embodiment 2

[0045] The reaction mixture of acetic acid and C4 containing acetic acid, sec-butyl acetate, C4 and C8 hydrocarbons is sent into the light component removal tower at a speed of 10t / h, wherein the content of acetic acid is 12.46wt%, and the content of sec-butyl acetate The content of C4 is 70.65wt%, the content of C4 is 10.73wt%, and the content of C8 hydrocarbon is 6.16wt%. C4 is used as the reflux at the top of the tower, and the other part is extracted as the product. Acetic acid, sec-butyl acetate and C8 hydrocarbons fall into the bottom of the tower, and are sent to the azeotropic distillation column after being extracted from the tower kettle. The operating conditions of the light component removal tower It is: the temperature at the top of the tower is -10°C, the temperature at the bottom of the tower is 110°C, the pressure is normal pressure, the reflux ratio is 1, and the number of theoretical plates is 20; Tower, sec-butyl acetate, water, and C8 hydrocarbons are evapo...

Embodiment 3

[0048] The reaction mixture of acetic acid and C4 containing acetic acid, sec-butyl acetate, C4 and C8 hydrocarbons is sent into the light component removal tower at a speed of 10t / h, wherein the content of acetic acid is 21.58wt%, and the content of sec-butyl acetate The content of C4 is 60.19wt%, the content of C4 is 18.11wt%, and the content of C8 hydrocarbon is 0.12wt%. C4 is used as the reflux at the top of the tower, and the other part is extracted as the product. Acetic acid, sec-butyl acetate and C8 hydrocarbons fall into the bottom of the tower, and are sent to the azeotropic distillation column after being extracted from the tower kettle. The operating conditions of the light component removal tower It is: the temperature at the top of the tower is -20°C, the temperature at the bottom of the tower is 105°C, the pressure is normal pressure, the reflux ratio is 5, and the number of theoretical plates is 30; Tower, sec-butyl acetate, water, and C8 hydrocarbons are evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com