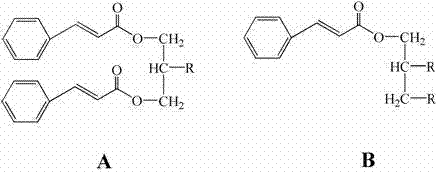

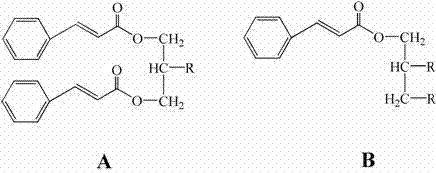

Acylglycerol cinnamate antioxidant and synthesis method thereof

A technology of cinnamic acid acylglycerol and antioxidant, which is applied in the field of antioxidants and their synthesis, cinnamate acylglycerol ester antioxidants and their synthesis, can solve the problem of few researches on catalytic synthesis, and achieves good color protection effect and efficient catalysis Reaction action, simple effect of product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 100 grams of ethyl cinnamate and 50 grams of soybean oil to a reaction flask equipped with a magnetic stirrer, then add 10 grams of a preconfigured composite catalyst (1-sulfonic acid butyl-3-methylimidazole p-toluenesulfonic acid Salt and monoisooctyl di-n-butyltin dimaleate, the compounding ratio is 5:1), the circulating water vacuum pump gives the system a vacuum degree of 98kPa, the heating temperature is 75°C, and the reaction is 8h. The reaction solution was centrifuged at 8000 r / min at 10°C for 6 minutes to separate the target product in the upper layer and the catalyst in the lower layer.

[0028] Under this reaction condition, obtain product 127.5g, product final yield is 85%.

Embodiment 2

[0030] 90 grams of vinyl cinnamate and 40 grams of soybean oil are added to the reaction flask equipped with a magnetic stirrer, and then 8.5 grams of pre-configured composite catalysts (1-sulfonic acid butyl-3-methylimidazole sulfonate and Monoisobutyl dimaleic acid di-n-butylnickel, the compounding ratio is 7:1), the circulating water vacuum pump gives the system a vacuum degree of 50kPa, the heating temperature is 85°C, and the reaction is 9.5h. The reaction solution was centrifuged at 10,000 r / min for 3 minutes at 6°C to separate the target product in the upper layer and the catalyst in the lower layer.

[0031] Under this reaction condition, obtain product 107.1g, product final yield is 89.25%.

Embodiment 3

[0032] Embodiment 3 (first instance catalyst recycling)

[0033] 110 grams of ethyl cinnamate and 40 grams of soybean oil were added to the reaction flask equipped with a magnetic stirrer, and then 9 grams of composite catalysts configured in advance (1-sulfonic acid propyl-3-methylimidazole p-toluenesulfonic acid Salt and lauric acid dibutyltin maleate, the compounding ratio is 5:1), the circulating water vacuum pump gives the system a vacuum of 80kPa, the heating temperature is 65°C, and the reaction is 12h. The reaction solution was centrifuged at 5000 r / min at 8°C for 8 minutes to separate the target product in the upper layer and the catalyst in the lower layer.

[0034] Under this reaction condition, obtain product 120.4g, product final yield is 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com