Preparation method of polyurethane foam immobilized microbe for treatment of azo dye sewage

A technology of immobilized microorganisms and polyurethane foam, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of low decolorization effect of immobilized microorganisms, and achieve the effect of improved effect and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention handles the preparation method of the polyurethane foam immobilized microorganism of azo dye sewage, and concrete steps are as follows:

[0019] Step 1, polyester polyol, triethanolamine, water, methyl silicone oil, dibutyltin dilaurate, and graphite felt powder after crushing are ultrasonically dispersed together for 5-10 seconds and then stirred and mixed evenly (polyester polyol, triethanolamine , water, methyl silicone oil, dibutyltin dilaurate, diphenylmethane diisocyanate MDI, the volume ratio between the crushed graphite felt powder is 100:2:2:2:1:100:1), and then Add diphenylmethane diisocyanate MDI, stir for 3-5 seconds until it turns white, and quickly transfer for 24 hours of natural foaming to obtain polyurethane foam. Cut the prepared polyurethane foam into small rectangular parallelepiped pieces with the same side length;

[0020] Step 2: Wash the polyurethane foam obtained in step 1 with distilled water for several times and then dry...

Embodiment 1

[0031] Step 1, 40ml of polyester polyol, 0.8ml of triethanolamine, 0.8ml of water, 0.8ml of methyl silicone oil, 0.3ml of dibutyltin dilaurate, and 3 pieces of crushed graphite felt powder (3×3cm) are ultrasonically dispersed together Stir and mix evenly after 5 seconds, then add 50ml of diphenylmethane diisocyanate MDI, stir for 5 seconds until it turns white, transfer it quickly for natural foaming for 24 hours, and obtain polyurethane foam, cut the prepared polyurethane foam into small cuboids with the same side length piece;

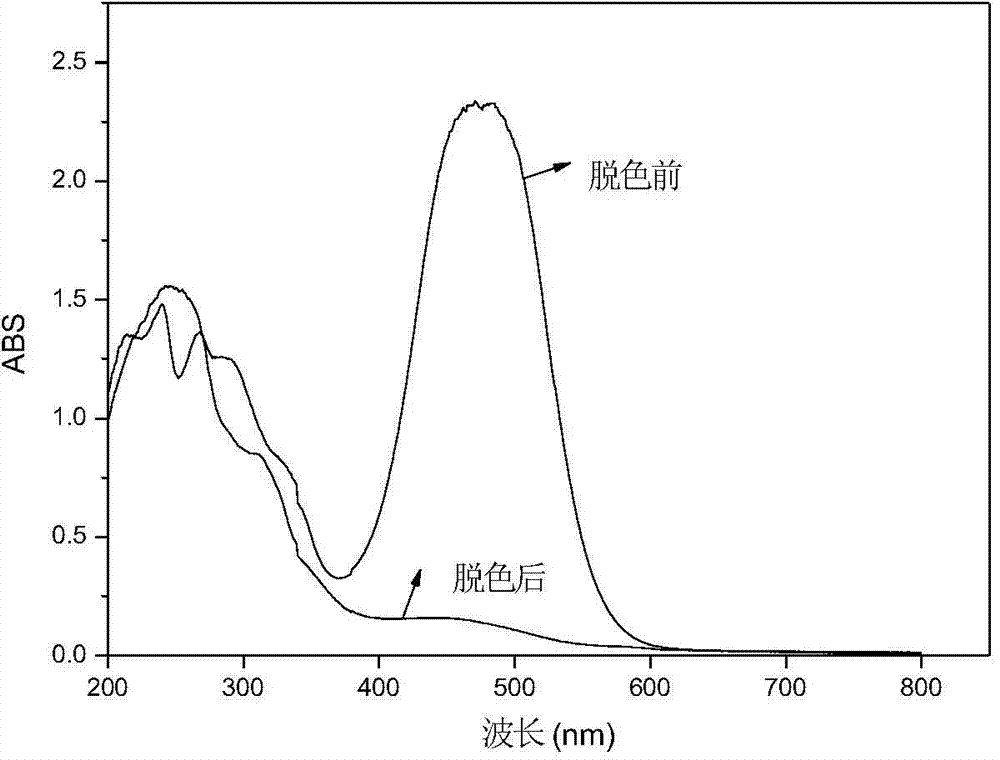

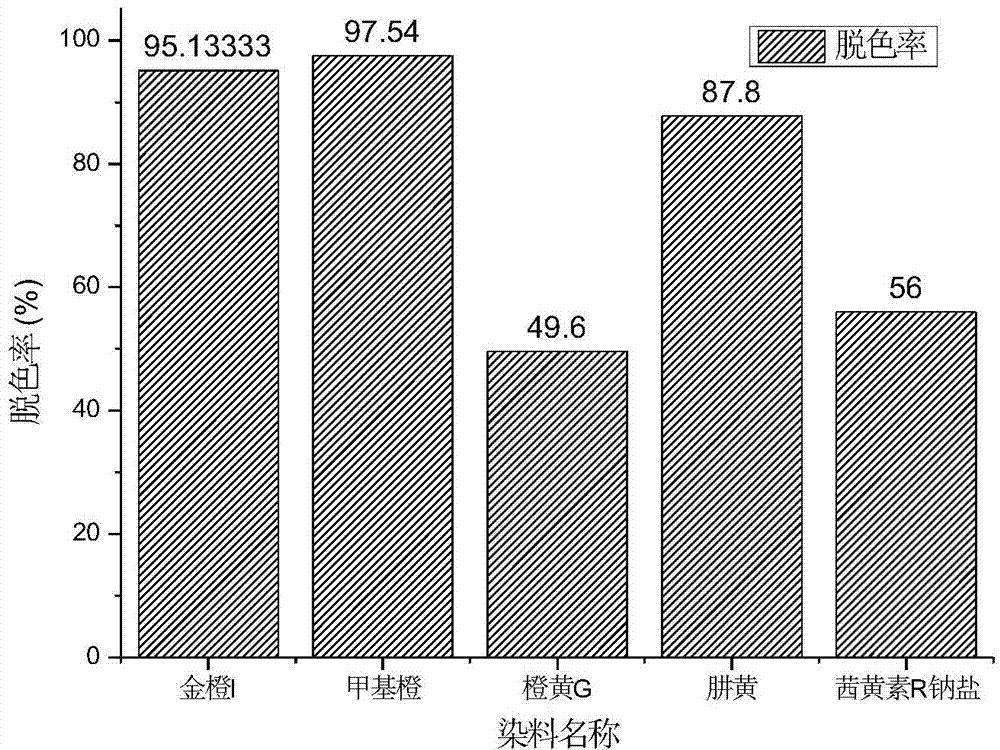

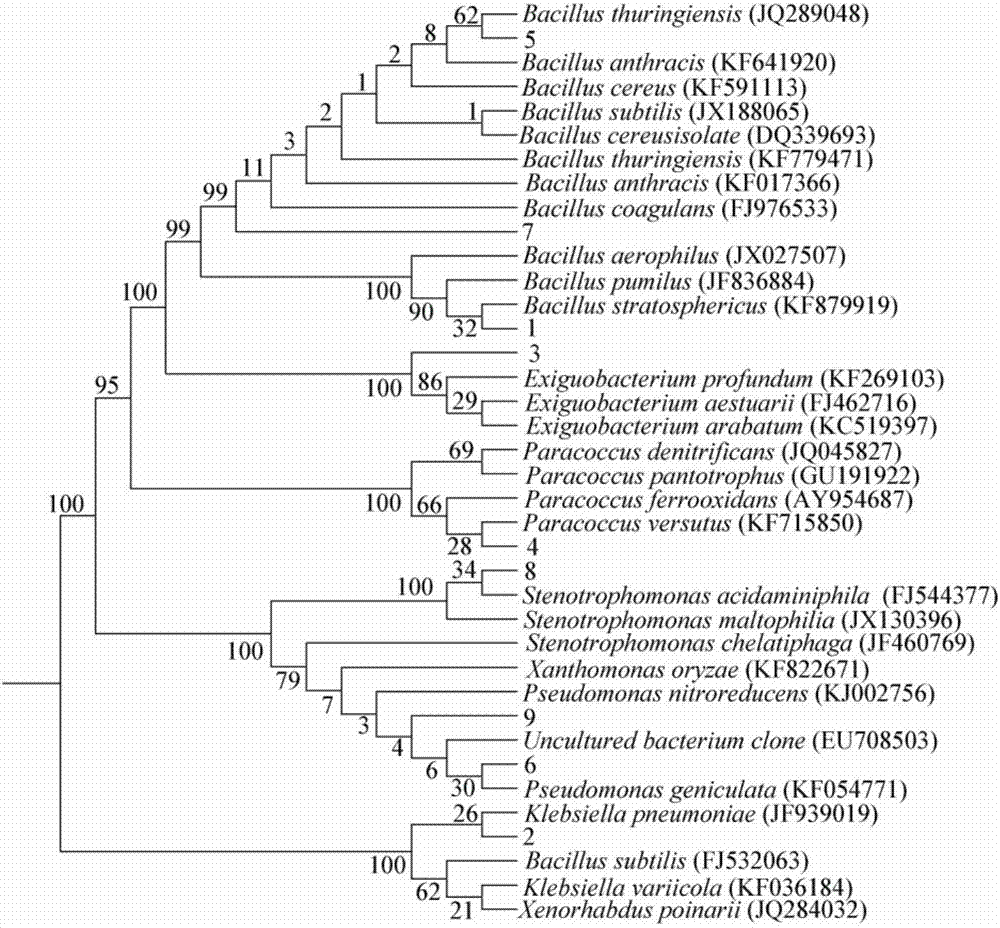

[0032]Step 2: Wash the polyurethane foam obtained in step 1 several times with distilled water and dry it to prepare LB medium for lysing broth. Put the polyurethane foam into the LB medium and sterilize it at 115°C for 30 minutes. After cooling, inoculate immobilized microorganisms Stenotrophomonas maltophilia strain T-8 was cultured with shaking at 25°C and 120rpm for 3 days, washed with distilled water several times, and polyurethane foam with imm...

Embodiment 2

[0034] Step 1, 40ml of polyester polyol, 0.8ml of triethanolamine, 0.8ml of water, 0.8ml of methyl silicone oil, 0.3ml of dibutyltin dilaurate, and 3 pieces of crushed graphite felt powder (3×3cm) are ultrasonically dispersed together Stir and mix evenly after 8 seconds, then add 50ml of diphenylmethane diisocyanate MDI, stir for 4 seconds until it turns white, transfer it quickly for natural foaming for 24 hours, and obtain polyurethane foam. Cut the prepared polyurethane foam into small cuboids with the same side length piece;

[0035] Step 2: Wash the polyurethane foam obtained in step 1 with distilled water for several times and then dry it to prepare LB medium for lysing broth. Put the polyurethane foam into the LB medium and sterilize it at 120°C for 25 minutes. After cooling, inoculate immobilized microorganisms Stenotrophomonas maltophilia strain T-8 was cultured with shaking at 30°C and 130rpm for 4 days, washed with distilled water several times, and polyurethane foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com