Method for preparing gypsum whisker

A technology for gypsum whiskers and whiskers, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of lack of preparation of gypsum whiskers, achieve the effects of protecting the environment, reducing production costs, and stabilizing chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

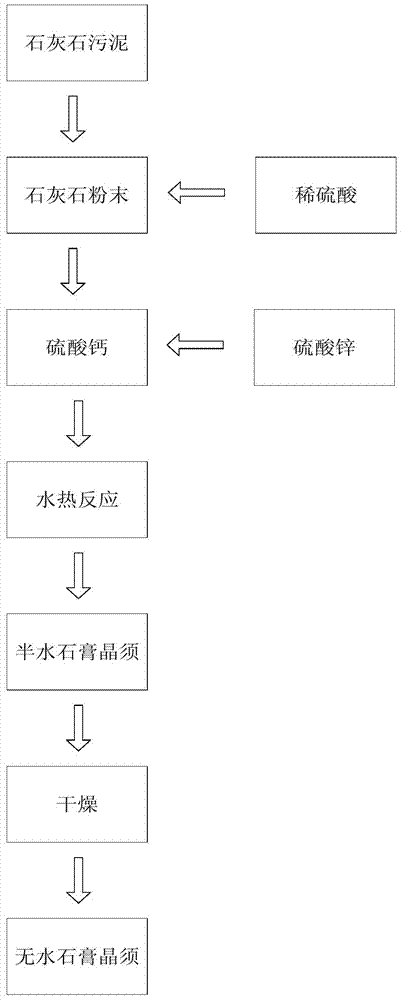

[0042] like figure 1 As shown, after drying limestone sludge at 500°C for 3 hours, limestone powder with a particle size of 1-10 μm was obtained. Get 50g of limestone powder, add 5wt% dilute sulfuric acid equal or excessive to the main component calcium carbonate in the limestone powder and react for 4 hours to generate calcium sulfate. After filtering the obtained calcium sulfate, add water to form a calcium sulfate solution and control the concentration of the solution to 10wt%, and then add zinc sulfate with a weight ratio of 1:20 to limestone as a catalyst. After heating in the kettle for 1 hour, take it out and filter, the filter material is hemihydrate gypsum whiskers, then immediately put the hemihydrate gypsum whiskers in a drying oven at 220°C for 1 hour to obtain anhydrous gypsum whiskers .

Embodiment 2

[0044] like figure 1 As shown, after drying limestone sludge at 500°C for 3 hours, limestone powder with a particle size of 1-10 μm was obtained. Get 50g of limestone powder, add 15wt% dilute sulfuric acid equal or excessive to the main component calcium carbonate in the limestone powder and react for 4 hours to generate calcium sulfate. After filtering the obtained calcium sulfate, add water to form a calcium sulfate solution and control the concentration of the solution to 10wt%, and then add zinc sulfate with a weight ratio of 1:20 to limestone as a catalyst. After heating in the kettle for 1 hour, take it out and filter, the filter material is hemihydrate gypsum whiskers, then immediately put the hemihydrate gypsum whiskers in a drying oven at 220°C for 1 hour to obtain anhydrous gypsum whiskers .

Embodiment 3

[0046] like figure 1 As shown, after drying limestone sludge at 650°C for 2 hours, limestone powder with a particle size of 1-10 μm was obtained. Get 50g of limestone powder, add 15wt% dilute sulfuric acid equal or excessive to the main component calcium carbonate in the limestone powder and react for 3 hours to generate calcium sulfate. After filtering the obtained calcium sulfate, add water to form a calcium sulfate solution and control the concentration of the solution to 30wt%, and then add zinc sulfate with a weight ratio of 1:20 to limestone as a catalyst. After 1.5 hours of water heating in the kettle, take it out and filter, the filter material is hemihydrate gypsum whiskers, and then put the hemihydrate gypsum whiskers in a drying oven at 210°C for 1.5 hours to obtain anhydrous gypsum whiskers .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com