In-situ electrochemical-surface enhanced raman scattering chip and production method thereof

A surface-enhanced Raman and in-situ electrochemical technology, which is applied in the fields of material electrochemical variables, Raman scattering, material excitation analysis, etc. Integration and other issues, to achieve the effect of high integration and miniaturization, easy fabrication and production, and reduced inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

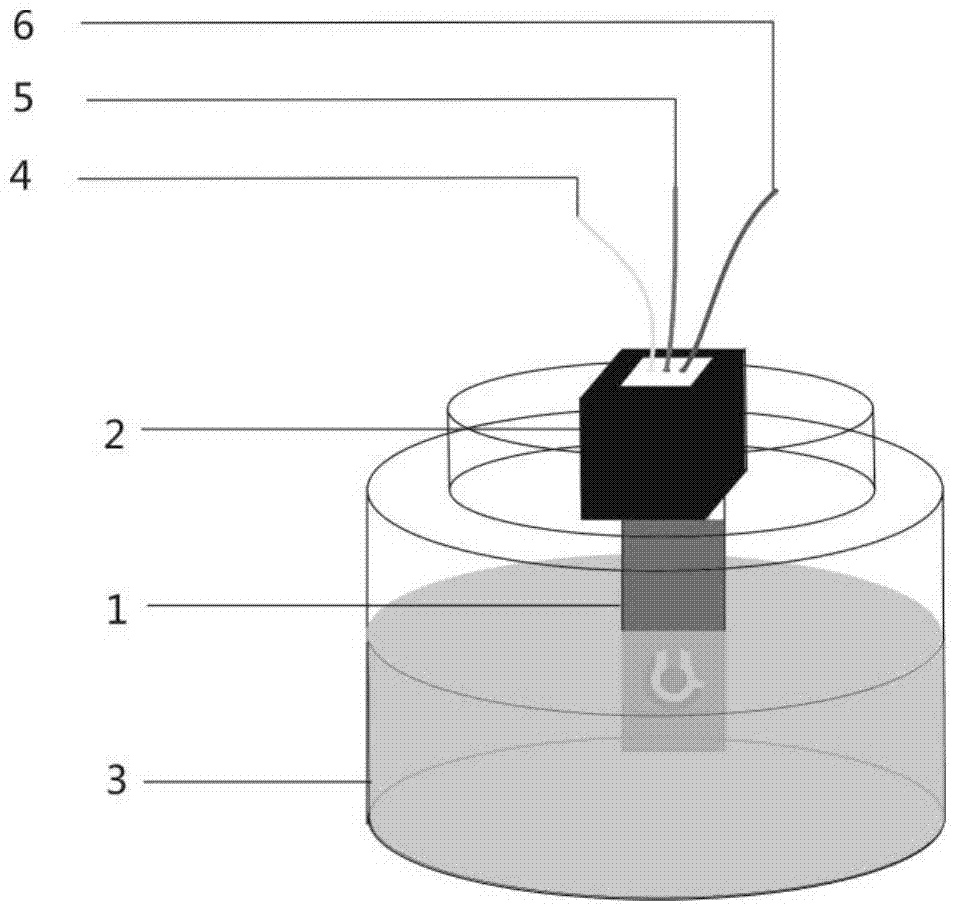

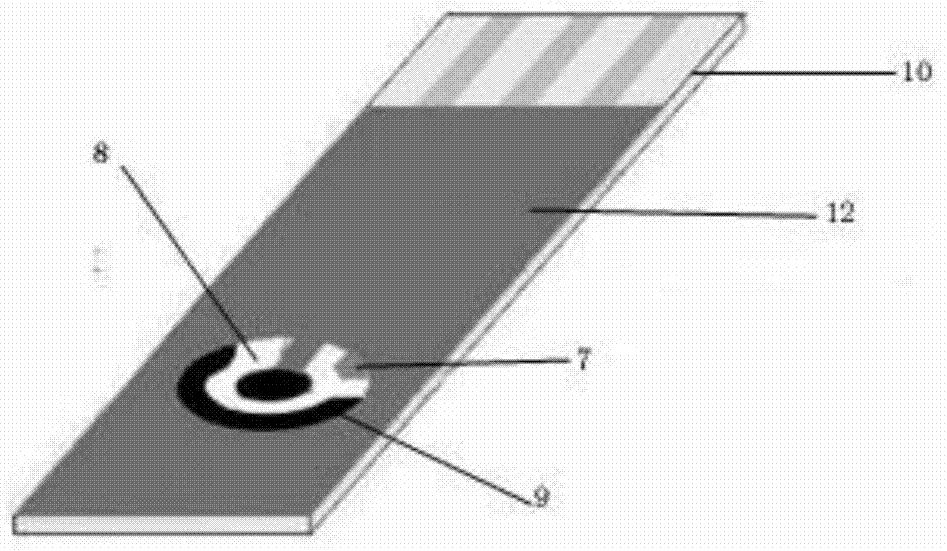

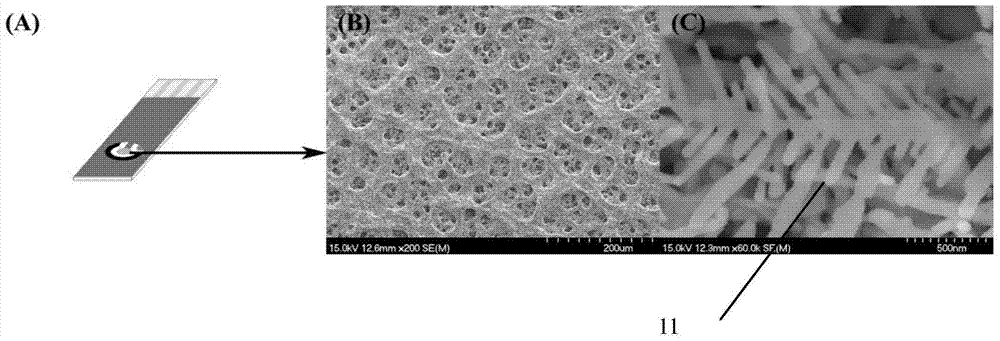

[0021] The in-situ electrochemical-surface-enhanced Raman spectroscopy chip described in this embodiment includes a substrate 10, which is a polyethylene terephthalate plate. The substrate 10 is provided with a conductive silver ink printing layer, a carbon ink printing layer, and a silver / silver chloride ink printing layer; a working electrode 8, a counter electrode 7 and a reference electrode 9 are integrated on the substrate, and the working electrode 8 and the counter electrode 7 Located on the carbon ink printing layer, the reference electrode 9 is located on the silver / silver chloride conductive ink printing layer; wherein the surface of the working electrode 8 is a porous nano-dendritic structure 11, and the surface layer of the chip is provided with a conductive end, a working electrode working end, and a counter electrode. The working end and the reference electrode working end, and other specific areas of the surface layer are insulating layers 12 . The insulating la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com