Scratch-resistant optical diffusion film and preparation method for same

An optical diffusion and scratch-type technology, applied in optics, optical components, instruments, etc., can solve the problems of easy scratching, troublesome preparation, and low light transmittance of prismatic films and other devices, so as to prevent scratching of prismatic films, Improved uniformity and coverage, excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

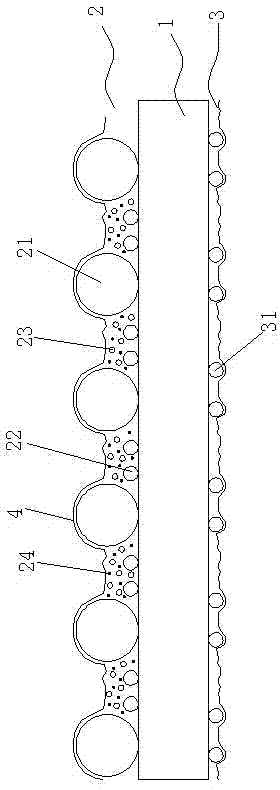

[0027] Such as figure 1 Shown is the structural representation of the present invention,

[0028] The reference signs are: substrate layer 1, light diffusion layer 2, anti-adhesion layer 3, large particles 21, medium particles 22, small particles 23, inorganic particles 24, anti-adhesion layer 3, anti-adhesion layer organic Particles 31 , resin film former 4 .

[0029] An anti-scratch optical diffusion film, comprising a substrate layer 1, the upper surface of the substrate layer 1 is coated with a light diffusion layer 2, and the lower surface of the substrate layer 1 is coated with an anti-adhesive layer 3, wherein , the light diffusion layer 2 includes resin film former 4, diffusion particles, cross-linking agent and solvent, the diffusion particles include organic particles and inorganic particles 24, the organic particles are composed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com