Method for preparing stomach-nourishing liquid milk and products thereof

A technology for liquid milk and stomach nourishment, applied in milk preparations, dairy products, applications, etc., can solve problems such as difficulty, precipitation, stratification, etc., and achieve the effects of rich nutrition, excellent flavor and excellent texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

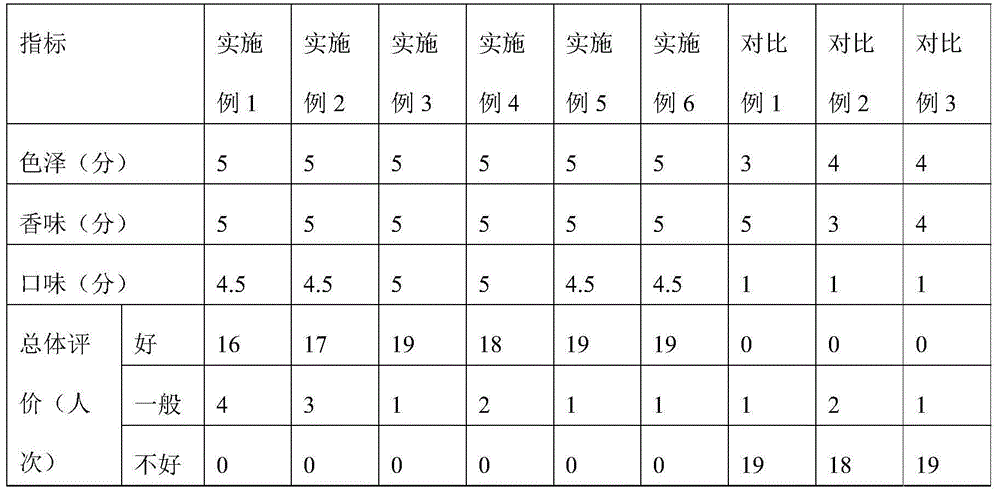

Examples

Embodiment 1

[0060] This embodiment is prepared with the components in the following formula table as raw materials:

[0061] The formula is shown in Table 1:

[0062] Table 1

[0063] Raw materials

Addition amount (%)

milk

80

Pumpkin powder

0.4

Yam powder

1.5

Millet noodles

1.5

0.02

Mono and diglycerin fatty acid esters

0.04

Water

16.54

[0064] The preparation steps are as follows:

[0065] 1. Add yam powder and millet powder to water at 60°C, keep it warm and stir for 20 minutes to make a gelatinized liquid.

[0066] The stirring speed is 50rpm, and the mass ratio of powder and water is 1:4;

[0067] 2. Heat the milk to 90°C, add the gelatinized liquid of step 1, as well as pumpkin powder, emulsifier and stabilizer, add water to a constant volume, keep it warm and stir for 5 minutes;

[0068] 3.75℃, 220bar homogenization;

[0069] 4.85℃, 10min pasteurization;

[0070] 5. Cool to 2°C;

[0071] 6. Filling.

Embodiment 2

[0073] This embodiment is prepared with the components in the following formula table as raw materials:

[0074] The formula is shown in Table 2:

[0075] Table 2

[0076] Raw materials

Addition amount (%)

milk

60

Pumpkin powder

0.3

Yam powder

2.5

Millet noodles

2.5

0.025

0.125

Mono and diglycerin fatty acid esters

0.045

Sucrose Fatty Acid Ester

0.035

Water

34.47

[0077] The preparation steps are as follows:

[0078] 1. Add yam powder and millet powder to water at 70°C, keep it warm and stir for 30 minutes to make a gelatinized liquid.

[0079] The stirring speed is 150 rpm, and the mass ratio of powder and water is 1:5;

[0080] 2. Heat the milk to 85°C, add the gelatinized liquid of step 1, as well as pumpkin powder, emulsifier and stabilizer, add water to a constant volume, keep it warm and stir for 10 minutes;

[0081] 3. 70℃, 180bar homogenization;

[0082] 4. 72℃, 15min pasteurization;

[0083] 5. Cool to 6°C;

[0084] 6. Filling.

Embodiment 3

[0086] This embodiment is prepared with the components in the following formula table as raw materials:

[0087] The formula is shown in Table 3:

[0088] table 3

[0089] Raw materials

Addition amount (%)

Goat milk

70

Pumpkin powder

0.5

Yam powder

1.0

Millet noodles

1.0

0.015

Mono and diglycerin fatty acid esters

0.03

Sucrose Fatty Acid Ester

0.02

Water

27.435

[0090] The preparation steps are as follows:

[0091] 1. After mixing the yam powder, millet powder, pumpkin powder, emulsifier, stabilizer and water evenly, transport them to the tubular heat exchanger. The heating temperature of the heat exchanger is 85℃ and the holding time is 15min to realize online Gelatinize

[0092] 2. Transfer the online gelatinized material in step 1 to the goat's milk in the batching tank, constant volume, and stir for 10 minutes;

[0093] 3.75℃, 180bar homogenization;

[0094] 4.130℃, 4s high temperature sterilization;

[0095] 5. Cool to 2°C;

[0096] 6. Filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com