Drying method and application of instant silver carp

A drying method and technology for silver carp, applied in the application, drying preservation of meat/fish, food preparation, etc., can solve the problems of not comprehensively considering the influence of drying process conditions, poor drying effect, etc., and achieve control of production cost, full taste, Technically Precise Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The research experiment of embodiment 1 pickling process.

[0046] In this embodiment, on the basis of the applicant's theoretical analysis and research, at first selected pickled ingredients by test comparison, then use single factor and composite factor test and sensory evaluation to determine the formula of each ingredient, and pickle environment and pickling time were studied, and the pickling environment and pickling time were determined.

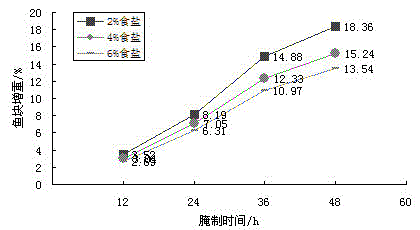

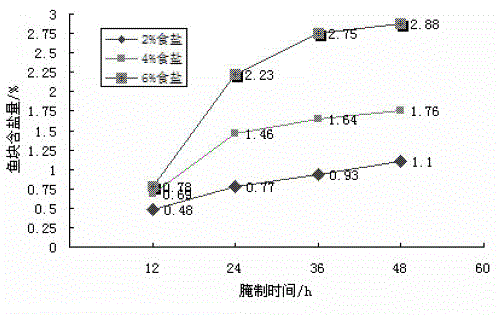

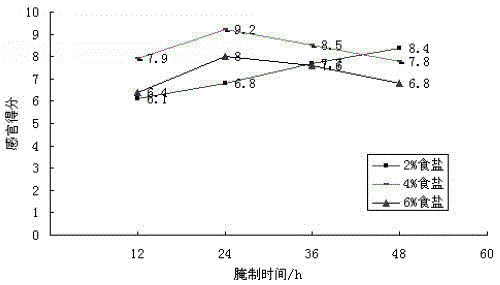

[0047] 1. The relationship between the amount of NaCl added, the curing time and the weight of fish pieces

[0048] Put the pre-treated fish pieces in the marinade and stir well. Taking the amount of salt added in the marinade as 2%, 4%, and 6% as an example, and marinating for 12h, 24h, 36h, and 48h under the environment of 0-4°C, the weight gain rate of the obtained fish nuggets decreased with time. The results of the changes are attached figure 1 shown. From attached figure 1 It can be seen that when the three additions ...

Embodiment 2

[0064] Embodiment 2 Research experiment of drying process.

[0065] Frying also has a drying effect. Fried dehydration is also a drying method that enhances flavor and preserves quality, and the way of frying is in line with consumers' pursuit of snack food taste. However, if the marinated fish pieces go directly into the frying process, the fried product will be whitish in color, charred on the outside and tender on the inside, and the meat will be loose. After sterilization, the shape of the fish pieces will be poor and will not form. , short shelf life. Therefore, the present invention first dries the fish pieces before frying them, which helps the fish pieces to be shaped and delicious, and helps to preserve the quality of the product. After continuous experiments and conclusions, the drying of the present invention adopts segmental drying, which can effectively control the drying effect and save energy.

[0066] 1. Relationship between moisture content and quality of f...

Embodiment 3

[0092] The research experiment of embodiment 3 frying technology.

[0093] The final moisture content of the product was obtained from the experimental research in Example 2, and under the guidance of the moisture content index, the frying process of the fish pieces was studied. In this example, through the determination of oil content and sensory evaluation, etc., the influence of frying temperature and frying time on product quality is mainly studied, and the temperature and time of frying are finally determined.

[0094] 1. The effect of frying temperature on the oil content of fish nuggets

[0095] as attached Figure 7 As shown, the higher the frying temperature and the longer the frying time, the higher the oil content of fish nuggets. This is mainly due to the oil getting into the fish pieces during frying. At the same temperature, the longer the frying time, the higher the oil content. When the temperature is low, the increase of oil content per unit time becomes s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com