Erdosteine powder inhalation and preparation method thereof

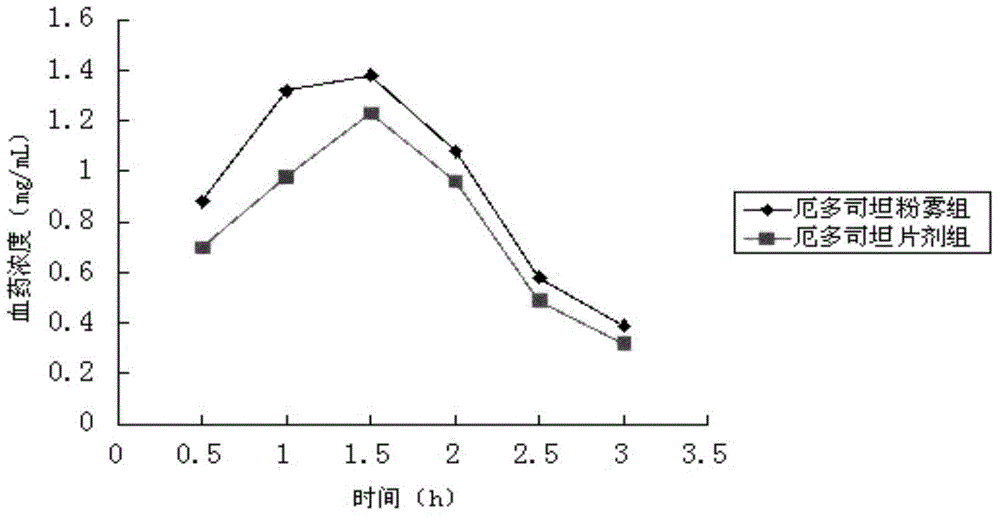

A technology for inhaling powder and erdosteine, which is applied in the field of medicine, can solve the problems of low bioavailability, achieve the effects of low preparation cost, good compliance, and increase the effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The present invention also provides a preparation method for erdosteine inhalation powder, comprising the following steps:

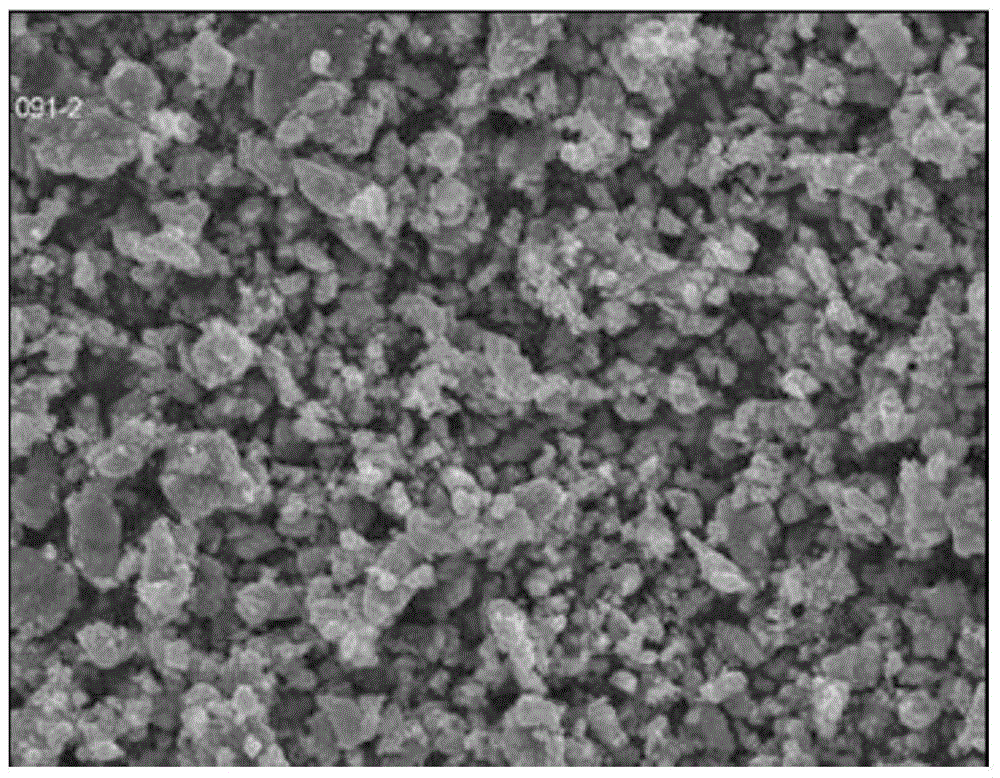

[0069] Step 1: grind erdosteine into fine powder, and use an ultrafine pulverizer to perform ultrafine pulverization to obtain erdosteine superfine powder with an average particle diameter of 1 μm to 5 μm; preferably, the obtained erdosteine superfine powder The average particle size is 2 μm to 4 μm.

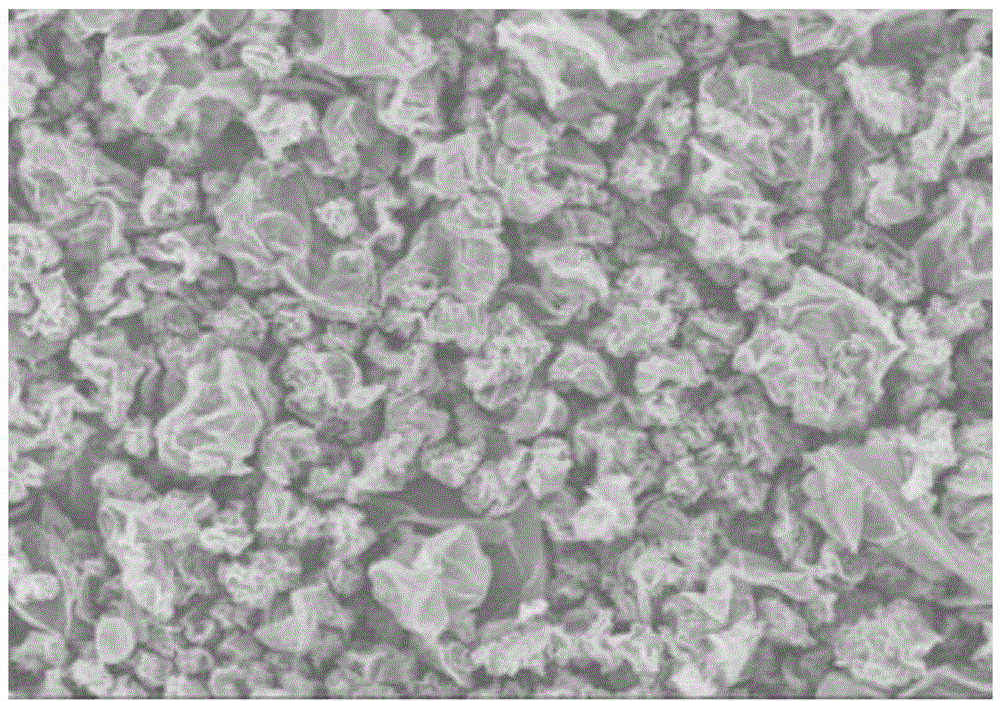

[0070] Step 2: Ultrafine pulverize Poloxamer 188 with an ultrafine pulverizer to obtain Poloxamer 188 ultrafine powder with an average particle size of 60 μm to 80 μm; preferably, the obtained Poloxamer 188 ultrafine powder The average particle size is 65 μm to 75 μm.

[0071] Step 3: Mix the pulverized erdosteine superfine powder and poloxamer 188 superfine powder at a mass ratio of 20:3 to 2:1, and pack them in capsules. In order to improve the effectiveness of the proportioning, preferably, after mixing the ground erdosteine superfi...

Embodiment 1

[0074] Grind the erdosteine drug finely, and perform ultrafine pulverization with an ultrafine pulverizer to obtain ultrafine dry powder of erdosteine with a particle diameter of 1 μm to 5 μm: pulverize Poloxamer 188 with a high-speed grinding pulverizer to obtain granules Poloxamer 188 ultrafine powder with a diameter of 60 μm to 80 μm; weigh 200 g of erdosteine ultrafine powder and 60 g of poloxamer 188 micropowder, and mix them in equal increments. After mixing well, fill No. 2 capsules, each Fill 260mg, make 1000 capsules, that is.

Embodiment 2

[0076] Grind the erdosteine drug finely, and use an ultrafine pulverizer for ultrafine pulverization to obtain an ultrafine powder with a particle size of 1 μm to 2 μm: pulverize Poloxamer 188 with a high-speed grinding pulverizer to obtain a particle size of 60 μm to 65 μm Poloxamer 188 superfine powder; weigh 200g of erdosteine superfine powder and 80g of poloxamer 188 micropowder, mix them according to the method of increasing in equal amounts, after mixing thoroughly, fill No. 2 capsules, each filled with 280mg, and make 1000 capsules, ready to serve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com