Method for industrially extracting alpha-amylase inhibitor in white kidney beans

The technology of an amylase inhibitor and white kidney bean is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, metabolic diseases, etc., and can solve the problems of incapability of industrialized large-scale application, inability to obtain active alpha-amylase inhibitors, and the like, Achieve the effect of promoting comprehensive utilization, increasing added value, and helping prevention and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

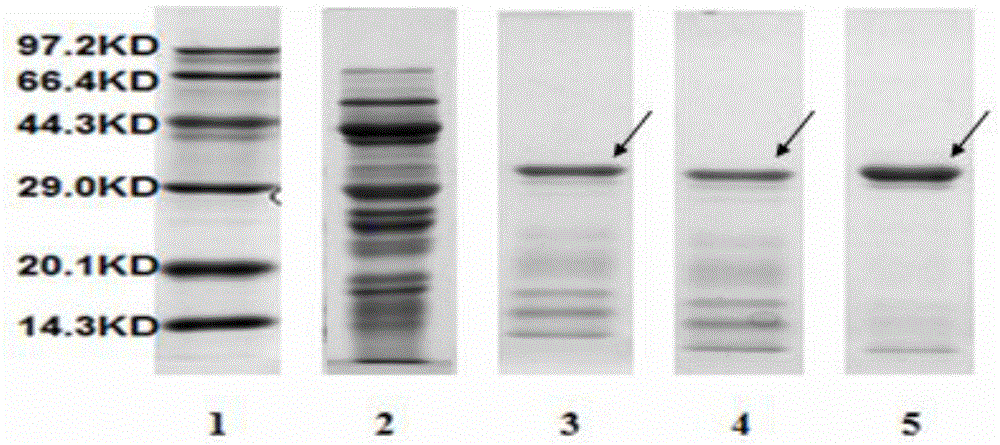

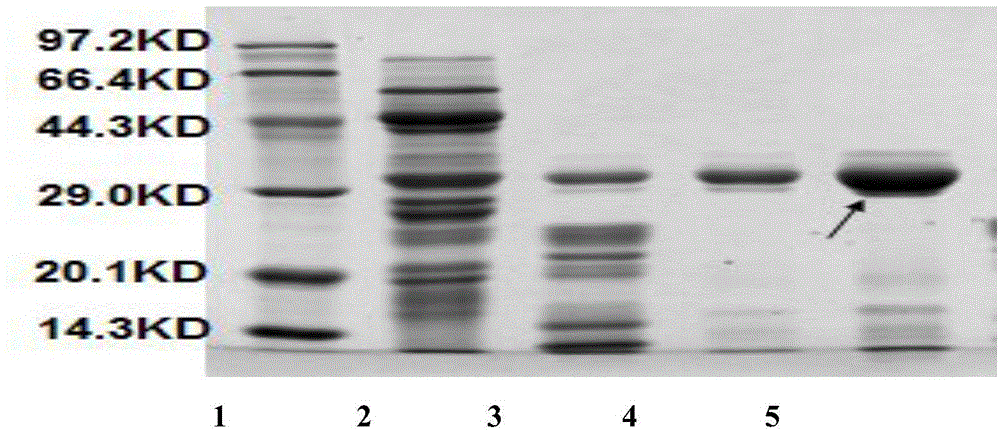

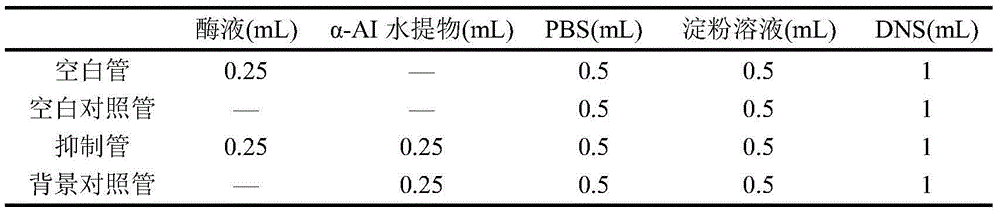

Method used

Image

Examples

Embodiment 1

[0059] Take 100g white kidney beans and soak them in 300mL distilled water for 10h at room temperature, then manually peel them;

[0060] Use a high-speed tissue masher to grind the peeled white kidney beans with 300mL of distilled water and pass through a 100-mesh sieve, then use 300mL of distilled water to refine again and pass through a 100-mesh sieve. After standing for 2 hours, centrifuge at 9000r / min for 20 minutes at 4°C, and take the supernatant;

[0061] Inactivate the supernatant in a water bath at 70°C for 30 minutes, centrifuge at 9000 r / min for 20 minutes at 4°C, and collect the supernatant;

[0062] Add absolute ethanol to the supernatant to a final concentration of 70% (v / v), stir at 4°C for 2h, centrifuge at 9000r / min for 20min at 4°C, and collect the precipitate, which is protein;

[0063] Put the protein in the fume hood for 1 hour, and dissolve it with 300mL 0.02mol / L, pH6.9 phosphate buffer to obtain the protein solution;

[0064] After adjusting the conc...

Embodiment 2

[0070] Take 100g white kidney beans and soak them in 400mL distilled water for 8 hours at room temperature, then manually peel them;

[0071] Use a high-speed tissue masher to grind the peeled white kidney beans with 400mL of distilled water and pass through a 100-mesh sieve, then use 300mL of distilled water to refine again and pass through a 100-mesh sieve. After standing for 3 hours, centrifuge at 9000r / min for 20 minutes at 4°C, and take the supernatant;

[0072] Inactivate the supernatant in a water bath at 70°C for 30 minutes, centrifuge at 9000 r / min for 20 minutes at 4°C, and collect the supernatant;

[0073] Add absolute ethanol to the supernatant to a final concentration of 70% (v / v), stir at 4°C for 2h, centrifuge at 9000r / min for 20min at 4°C, and collect the precipitate, which is protein;

[0074] After the protein was placed in a fume hood for 2 hours, it was dissolved with 400 mL of 0.02 mol / L, pH 6.9 phosphate buffer to obtain a protein solution.

[0075] Aft...

Embodiment 3

[0081] Take 100g white kidney beans and soak them in 500mL distilled water for 7 hours at room temperature, then manually peel them;

[0082] Use a high-speed tissue masher to grind the peeled white kidney beans with 400mL of distilled water and pass through a 100-mesh sieve, then re-fine the sieve with 400mL of distilled water and pass through a 100-mesh sieve, discard the sieve, combine the filtrate, and statically After standing for 2 hours, centrifuge at 9000r / min for 20 minutes at 4°C, and take the supernatant;

[0083] Inactivate the supernatant in a water bath at 70°C for 30 minutes, centrifuge at 9000 r / min for 20 minutes at 4°C, and collect the supernatant;

[0084] Add absolute ethanol to the supernatant to a final concentration of 70% (v / v), stir at 4°C for 2h, centrifuge at 9000r / min for 20min at 4°C, and collect the precipitate, which is protein;

[0085] After the protein was placed in a fume hood for 1.5 h, it was dissolved with 200 mL of 0.02 mol / L, pH 6.9 pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com