Super-hydrophobic single-plate digital micro-droplet transport device, and manufacturing method thereof

A digital micro and super-thin technology, applied in the field of digital microfluidic technology and biomedicine, can solve the problem of high dielectric constant, achieve the effect of maintaining biological activity, convenient operation, and improving feasibility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

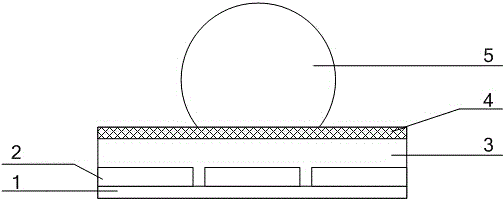

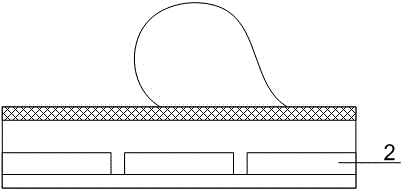

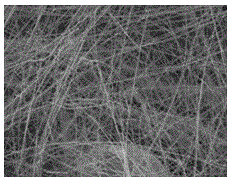

[0025] Embodiment 1: The superhydrophobic unipolar plate micro-droplet transport device in this embodiment has a unipolar plate structure to better realize the purpose of droplet transport. like figure 1 As shown, from bottom to top are substrate 1, electrode 2, dielectric layer 3, and hydrophobic layer 4, wherein: substrate 1 is an insulating glass substrate, electrode 2 is an ITO glass electrode array, and superhydrophobic layer 4 is boron nitride nanotubes .

[0026] The specific manufacturing process of the above-mentioned superhydrophobic unipolar plate micro-droplet transport device is as follows: first, the insulating glass substrate is cleaned; then, a layer of indium tin oxide (ITO) is coated on the insulating glass substrate by sputtering, evaporation and other methods. film; then through photolithography, development, etching and other steps, the ITO glass electrode array is produced; then a layer of dielectric layer is deposited on the ITO glass electrode array b...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment is different from Embodiment 1 in that the electrode 2 is an Au / Cr thin film electrode.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment is different from Embodiment 1 in that the electrode 2 is an Au / Ti thin film electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com