Column nail roller surface repairing method of novel high-pressure roller mill

A technology of high-pressure roller mills and repair methods, which is applied in the direction of welding media, arc welding equipment, welding/cutting media/materials, etc., can solve the problems of lack of effective repair technology, reduced equipment operation rate, and reduced roller surface life. The effect of strong bonding, short time required, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

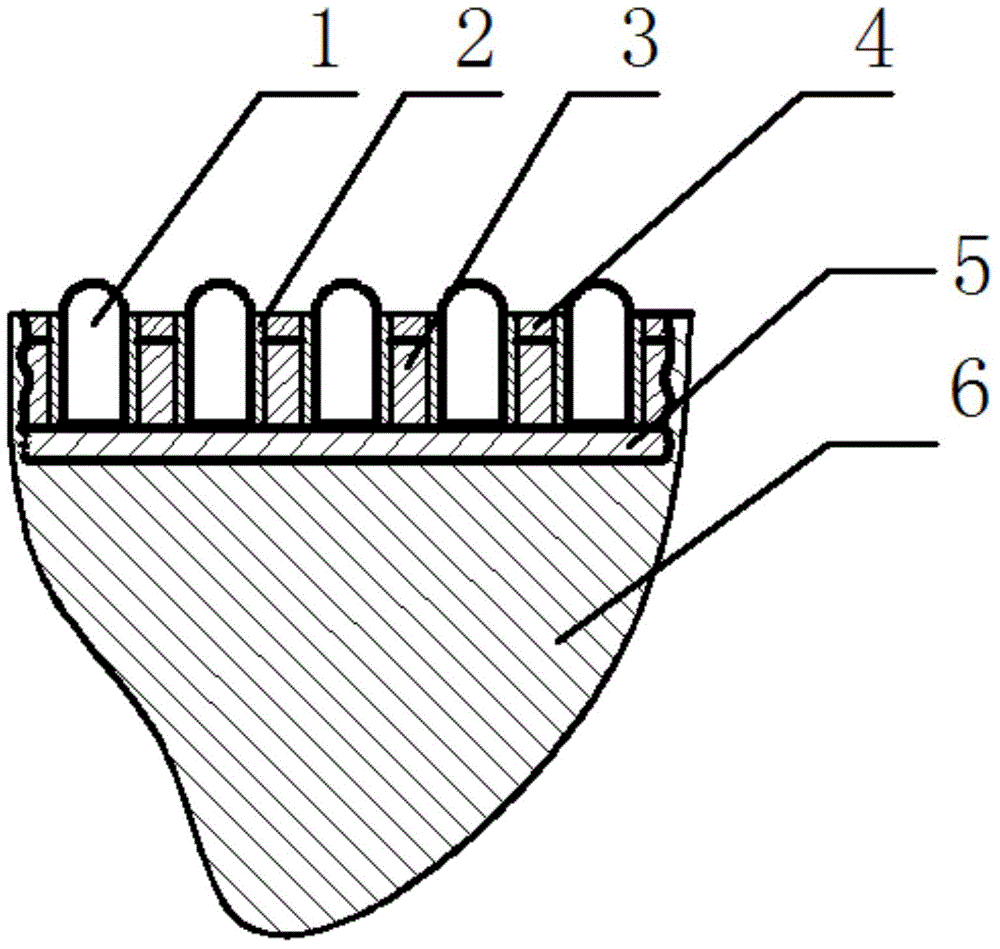

[0032]Due to various reasons, the surface of the stud roller surface of the roller sleeve of the high-pressure roller mill will fall off with the matrix, and the thickness of the shedding is basically the same as the length of the stud. Once this peeling phenomenon occurs, the roller surface must be repaired, otherwise the equipment will be unusable, and the entire roller sleeve will eventually be replaced.

[0033] A method for repairing the roller surface of a stud roller surface high-pressure roller mill, the steps of which are as follows:

[0034] (1) Select the high-pressure roller mill roll surface 6 with pits on the surface to be repaired, and clean the pits. To clean the pits, first use a gas cutting gun to cut off the stripped surface, and then use a grinder to grind the bottom surface and the surface 1 cm away from the edge. Edge polishing, slag cleaning;

[0035] (2) Surfacing a layer of 3mm thick connection layer 5 at the bottom of the pit, using MIG welding, the ...

Embodiment 2

[0042] A method for repairing the roller surface of a stud roller surface high-pressure roller mill, the steps of which are as follows:

[0043] (1) Select the roll surface of the high-pressure roller mill with pits on the surface to be repaired, and clean the pits. To clean the pits, first use a gas cutting gun to cut off the stripped surface, and then use a grinder to grind the bottom surface and the edge to 1 cm away from the edge. Polishing, deslag cleaning;

[0044] (2) Surfacing a layer of 3mm thick connection layer at the bottom of the pit, using MIG welding, the composition and mass fraction of the welding wire material are: carbon content is 2%, chromium content is 23%, nickel content is 10%, The balance is iron; the diameter of the welding wire is 1.2mm; the current is 125A; the voltage is 22V; the welding speed is 15cm / min;

[0045] (3) prepare the cemented carbide stud that is sheathed with stainless steel sleeve, the material of cemented carbide stud is tungsten ...

Embodiment 3

[0051] A method for repairing the roller surface of a stud roller surface high-pressure roller mill, the steps of which are as follows:

[0052] (1) Select the roll surface of the high-pressure roller mill with pits on the surface to be repaired, and clean the pits. To clean the pits, first use a gas cutting gun to cut off the stripped surface, and then use a grinder to grind the bottom surface and the edge to 1 cm away from the edge. Polishing, deslag cleaning;

[0053] (2) Surfacing a layer of 3mm thick connection layer at the bottom of the pit, using MIG welding, the composition and mass fraction of the welding wire material are: carbon content is 2%, chromium content is 20%, nickel content is 12%, The balance is iron; the diameter of the welding wire is 1.2mm; the current is 125A; the voltage is 24V; the welding speed is 15cm / min;

[0054] (3) prepare the cemented carbide stud that is sheathed with stainless steel sleeve, the material of cemented carbide stud is tungsten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com