Continuous forming device for hollow composite board-wood plastic composite material and application thereof

A wood-plastic composite material and composite board technology, applied in the field of composite materials, can solve the problems of easy agglomeration, uneven dipping, and wood-plastic weight, and achieve the effect of improving the compressive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

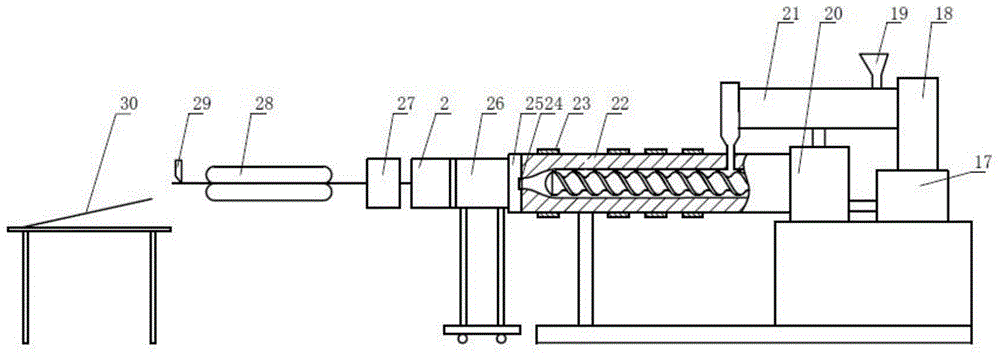

[0061] Release film (upper mold unwinding device, lower mold unwinding device), 3mm thick hollow fabric woven from glass fiber (hollow cloth unwinding device) and continuous glass fiber (first and second felting devices) Place them in the designated positions respectively, after that, preheat the curing room to 90°C and keep it warm for 30 minutes; start the lower film unwinding device and the storage tank delivery pump, blend the phenolic resin, curing agent and reinforcing agent and transport them to the spraying device, so that Form fine droplets and evenly disperse on the lower film, wherein, the mass ratio of phenolic resin (phenolic resin 2130), curing agent (NL-1 phenolic resin curing agent) and reinforcing agent (aminopropyltetraethoxysilane) is 100:10:6.5, the mass ratio of 3D hollow fabric and resin matrix is 1:1; after that, when the material runs under the hollow fabric, open the cloth opening device; similarly, when the material passes through the secondary spray...

Embodiment 2

[0063] Basically the same as Example 1, the difference is: the mass ratio of thermosetting resin, curing agent and reinforcing agent is 100:6:8; wood flour, thermoplastics PE, coupling agent, calcium powder and lubricant, its quality The percentages are respectively 52% of wood powder, 35% of thermoplastic PE, 3% of coupling agent (silane coupling agent KH550), 7% of calcium powder and 3% of lubricant (paraffin wax) (the specific gravity of the obtained wood plastic is 1.15g / cm 3 ); what the upper and lower surfaces of the hollow fabric adopted is grid cloth (that is, embodiment 1 does not open the first grid cloth unwinding device and the second grid cloth unwinding device, and embodiment 2 will open the first grid cloth unwinding device and the second grid cloth unwinding device, and stop the first felting device and the second felting device). The density is 0.89g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com