Method and stirring device for producing crystalline monoammonium phosphate by using wet method to purify phosphoric acid

A monoammonium phosphate, wet purification technology, applied in the direction of phosphate, phosphorus oxyacids, etc., can solve the problems of high purity crystal monoammonium phosphate, unsatisfactory purity, long crystallization time, etc., to achieve good appearance quality, Good crystallization effect, good product crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

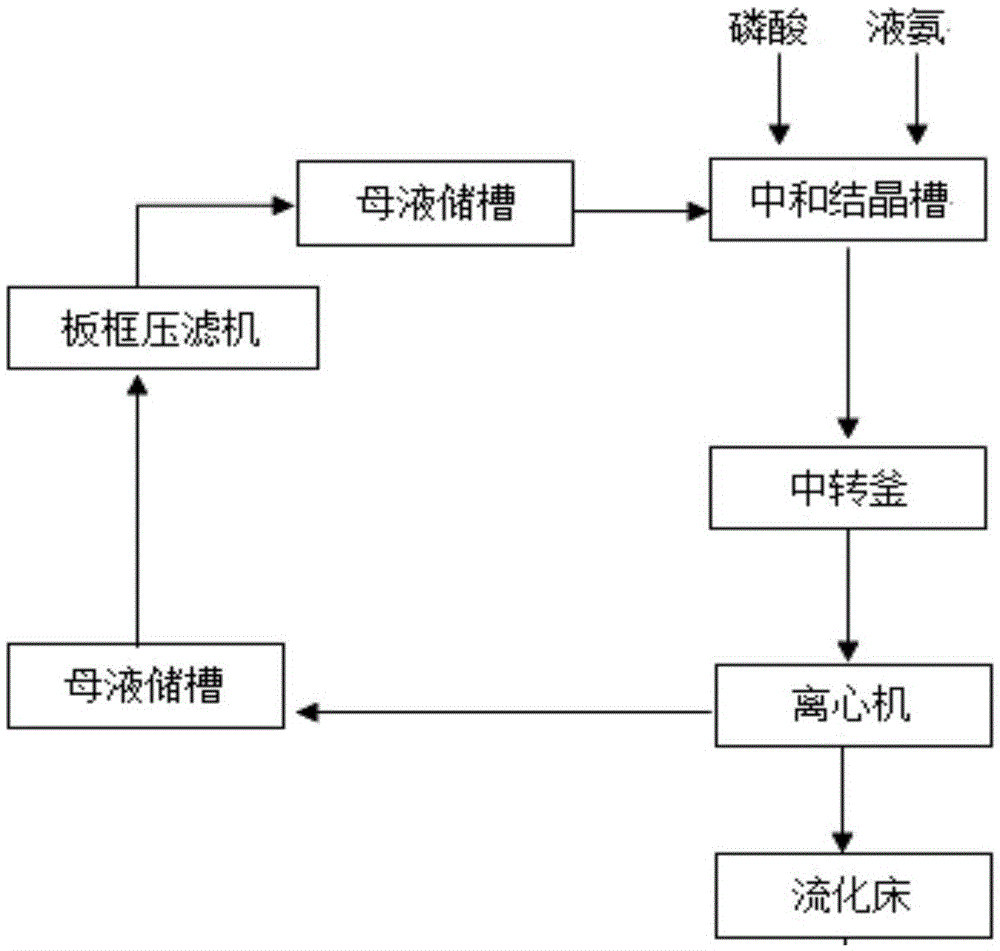

[0073] A method for producing crystalline monoammonium phosphate by wet purification of phosphoric acid, comprising the following steps:

[0074] (1) After adding a preset amount of mother liquor in the neutralization tank, add purified wet-process phosphoric acid with a metered purity of 85% and mix until the mass concentration of phosphoric acid in the mixed solution is 35-45%;

[0075] (2) Start the stirring device, add ammonia to neutralize by adding liquid ammonia at multiple points, control the speed of adding liquid ammonia, and continue adding for 80-100 minutes until the pH value of the solution reaches 4.2-4.6, stop neutralization;

[0076] (3) After passing the test, enter the cooling and crystallization stage;

[0077] (4) After the crystallization is completed, the slurry is dehydrated and dried to obtain crystalline monoammonium phosphate, and the detached mother liquor is sent to the mother liquor storage tank for recycling.

Embodiment 2

[0079] A method for producing crystalline monoammonium phosphate by wet purification of phosphoric acid, comprising the following steps:

[0080] (1) After adding a preset amount of mother liquor in the neutralization tank, add purified wet-process phosphoric acid with a metered purity of 85% and mix until the mass concentration of phosphoric acid in the mixed solution is 40%;

[0081] (2) Start the stirring device, add liquid ammonia to neutralize by adding ammonia at multiple points, control the speed of adding liquid ammonia, continue adding for 90 minutes until the pH value of the solution reaches 4.3, and stop neutralization;

[0082] (3) After passing the test, enter the cooling and crystallization stage; when starting to cool, use natural cooling; when the slurry temperature drops to 70°C, turn on the reactor jacket cooling water for forced cooling; until the temperature drops to normal temperature, the cooling time The control is 90 minutes.

[0083] (4) After the cry...

Embodiment 3

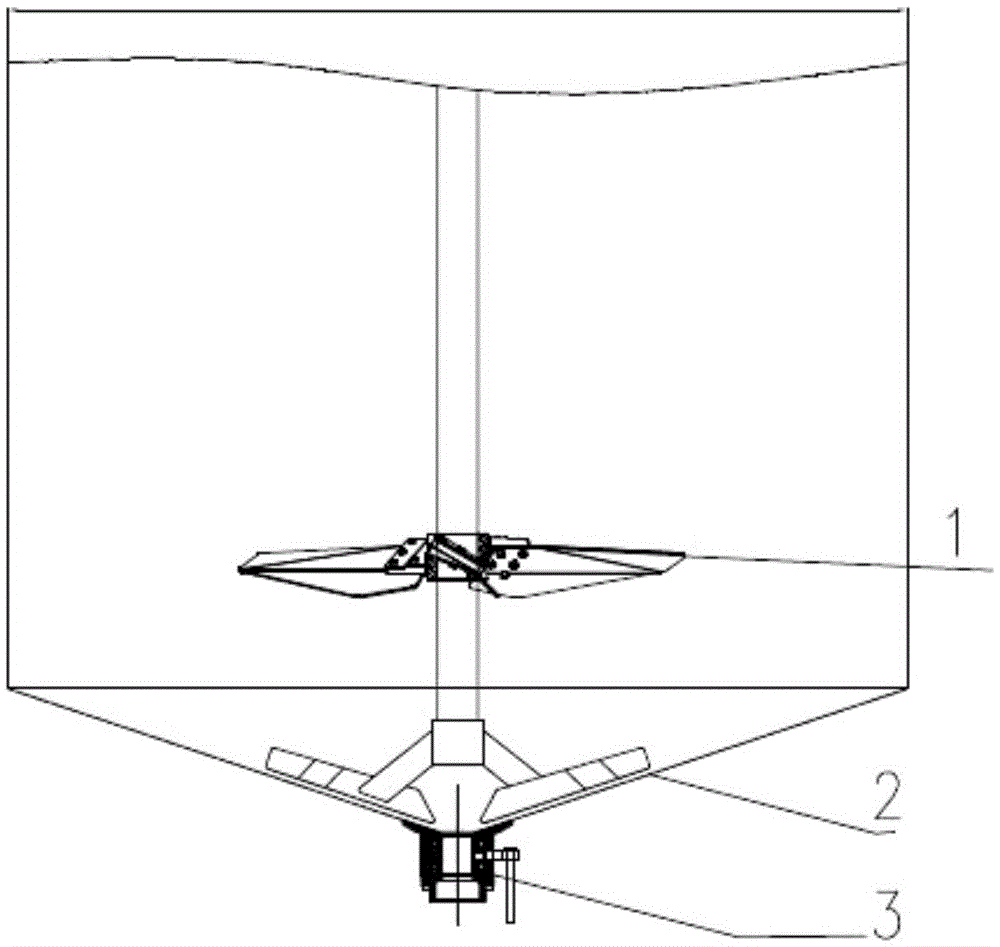

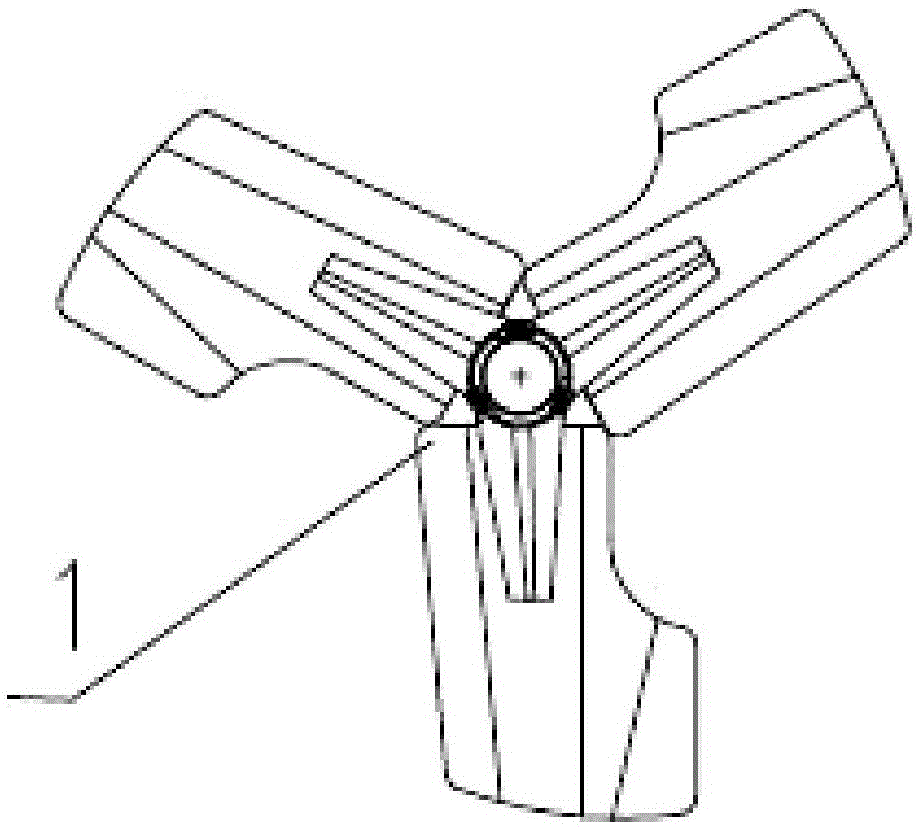

[0085]The stirring device used in the method for producing crystalline monoammonium phosphate by using wet purification phosphoric acid is characterized in that it includes a stirring bin and a stirring paddle; shaft 3, and the stirring blades arranged on the fixed shaft 3;

[0086] The stirring paddle is provided with a first stirring paddle 1 and a second stirring paddle 2, both sleeved on the fixed shaft 3; the blade surface of the first stirring paddle 1 is horizontal and in an "L" shape structure, one end of which is fixedly connected to the central shaft, and the other end extends horizontally; the blade of the second stirring paddle 2 is arc-shaped, one end of which is fixedly connected to the central shaft, and the other end extends horizontally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com