Hydrothermal preparation method for nanometer NbO2F powder

A powder and nano technology, applied in the field of preparation of nano NbO2F powder, to achieve the effect of process safety and environmental protection, cost saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

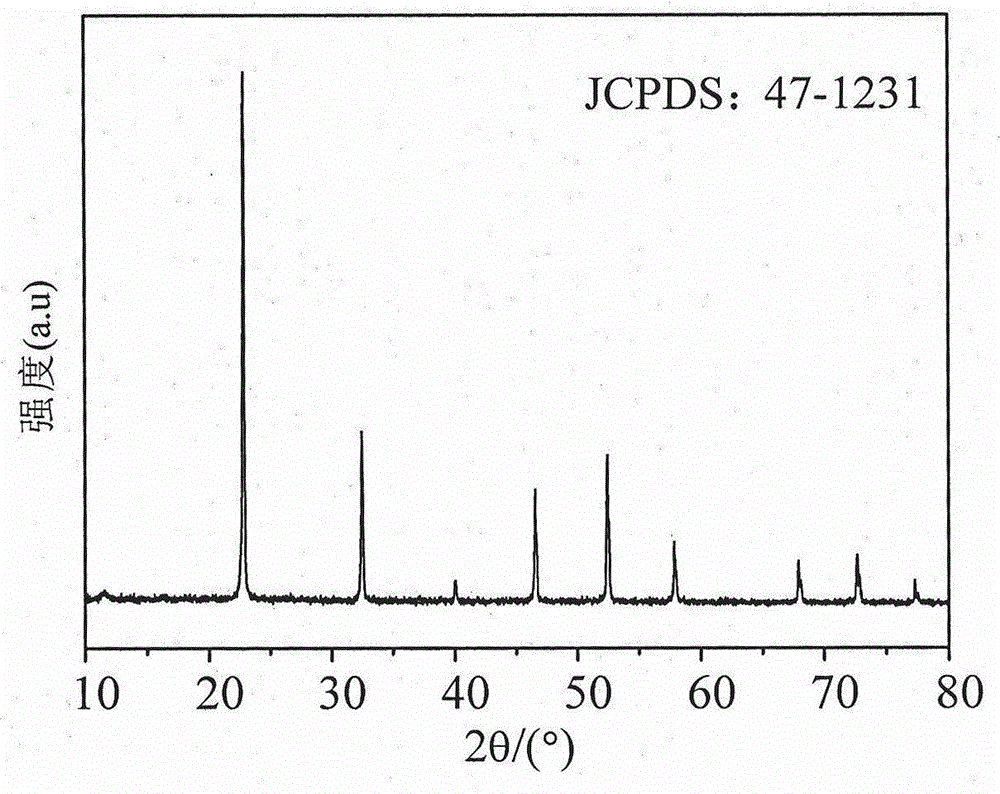

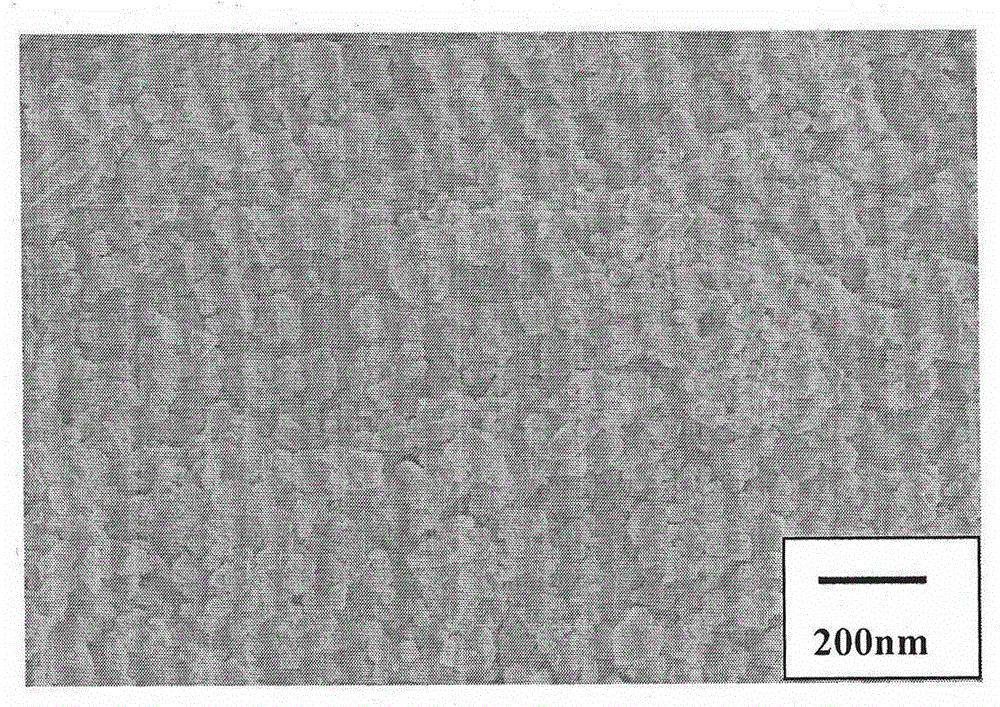

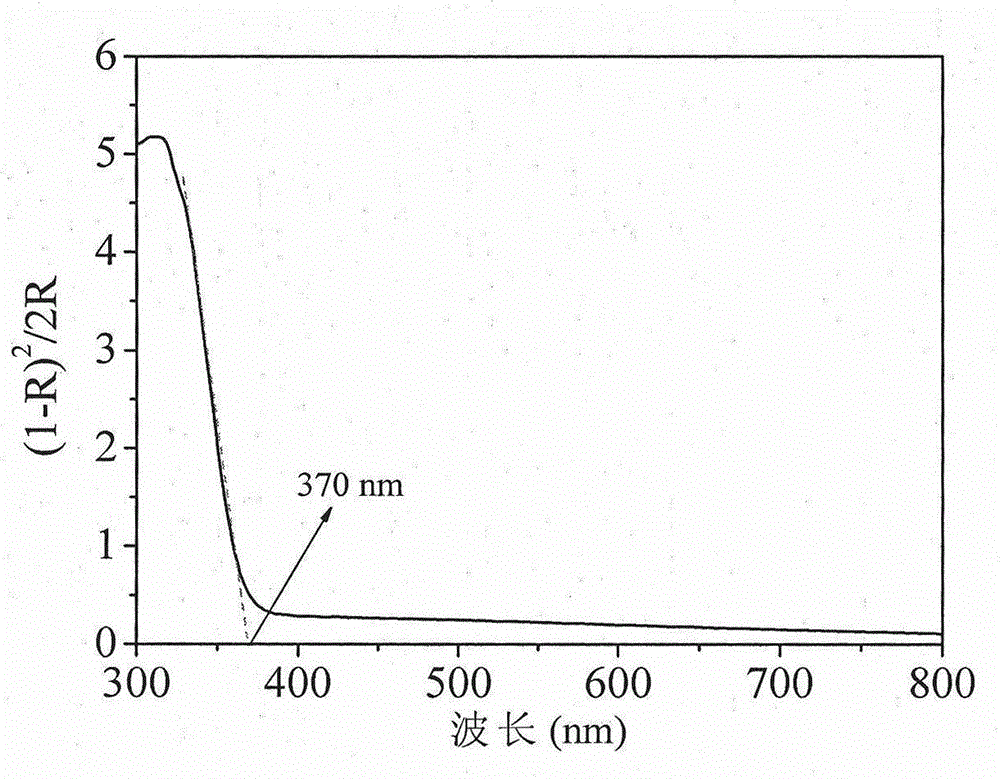

Embodiment 1

[0024] At room temperature, weigh 0.005 moles of Nb 2 o 5 Powder, the powder is transferred to a volume of 100ml and has a polytetrafluoroethylene-lined reactor; in the fume hood, add 0.25 mole HF (that is, 25 grams of mass percent concentration is 20% hydrofluoric acid solution), then add 3ml of polyvinyl alcohol (PVA-124) solution with a concentration of 2.0g / L, and stir the reaction kettle evenly with a glass rod. Place the reaction kettle in an oven at 180°C for 24 hours of constant temperature reaction, let the reaction kettle cool down to room temperature naturally in the oven, pour the product in the reaction kettle into a plastic beaker, filter and wash 3 times, and finally put the product in the Dry in an oven at 80°C to get Nb 2 o 5 Powder products. Carry out X-ray diffraction analysis (XRD), scanning electron microscope (SEM) and ultraviolet-visible diffuse reflectance absorption spectrum (DRS) test to the product obtained respectively, the result is as follows:...

Embodiment 2

[0030] At room temperature, weigh 0.015 moles of Nb 2 o 5 Powder, the powder is transferred to a volume of 100ml and has a polytetrafluoroethylene-lined reactor; in a fume hood, add 0.375 moles of HF (i.e. 37.5 grams of 20% hydrofluoric acid concentration in the reactor) acid solution), and then add 9ml of polyvinyl alcohol (PVA-124) solution with a concentration of 2.0g / L, stir evenly with a glass rod, and seal the reaction kettle. Put the reaction kettle in an oven at 190°C for 18 hours of constant temperature reaction, let the reaction kettle cool down to room temperature naturally in the oven, pour the product in the reaction kettle into a plastic beaker, filter and wash 3 times, and finally put the product in the Drying in an oven at 60°C to obtain nano-NbO 2F powder products. According to the same photocatalytic experimental method as in Example 1, when the photocatalytic degradation of 20mg / L MO solution was carried out for 50 minutes, the MO decolorization rate reac...

Embodiment 3

[0032] At room temperature, weigh 0.10 moles of Nb 2 o 5 Powder, the powder is transferred to a volume of 100ml and has a polytetrafluoroethylene-lined reactor; in the fume hood, add 4.0 moles (that is, 40 grams of mass percent concentration is 20% hydrofluoric acid solution in the reactor) ), then add 6ml of polyvinyl alcohol (PVA-124) solution with a concentration of 2.0g / L, and stir the reaction kettle evenly with a glass rod. Place the reaction kettle in an oven at 190°C for 12 hours of constant temperature reaction, let the reaction kettle cool down to room temperature naturally in the oven, pour the product in the reaction kettle into a plastic beaker, filter and wash 3 times, and finally put the product in the Drying in an oven at 70°C to obtain nano-NbO 2 F powder products. According to the same photocatalytic experimental method as in Example 1, when the photocatalytic degradation of 20mg / L MO solution was carried out for 50 minutes, the MO decolorization rate reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com