Method for preparing acetyl bromide from phosphorus tribromide

A technology of phosphorus tribromide and acetyl bromide, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problem of wasting a lot of manpower and material resources, increasing production costs of enterprises, unsuitable control of the amount of liquid bromine, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

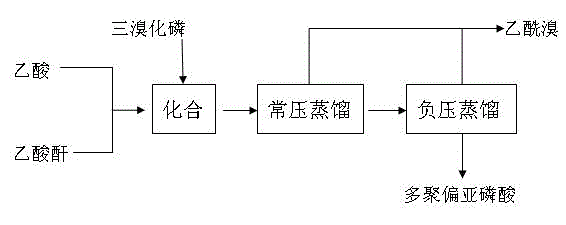

[0028] Example 1: like figure 1 Shown:

[0029] 1) Add 180g (3mol) acetic acid and 306g (3mol) acetic anhydride to a dry and clean 1000ml four-neck flask, stir, cool down to below 20°C, add 830g (3.06mol) phosphorus tribromide dropwise, and slowly heat up to 30°C ℃ for 2 hours, then heated to reflux for 0.5 hours.

[0030] 2) Start steaming at normal pressure for 6 hours, then distill under reduced pressure for 2 hours until no liquid is evaporated.

[0031] 3) A total of 1087g of acetyl bromide was distilled, and the GC purity was 98.3%;

[0032] Keep the water bath at 80°C, add 100ml of 80°C hot water dropwise to the flask, cool to obtain white crystals, filter and dry to obtain 185g of phosphorous acid with a content of 98.6%.

Embodiment 2

[0033] Example 2: Example 2 repeats the test of example 1: as figure 1 Shown:

[0034] 1) Add 180g of acetic acid and 306g of acetic anhydride to a dry and clean 1000ml four-neck flask, stir, cool down to below 20°C, add 830g of phosphorus tribromide dropwise, slowly raise the temperature to 30°C and keep it warm for 2 hours, then raise the temperature to reflux, keep warm and reflux 0.5 hours.

[0035] 2) Start steaming at normal pressure for 8 hours, then distill under reduced pressure for 2 hours until no liquid is evaporated. Acetyl bromide 1092g was obtained with a purity of 98.6%.

[0036] 3) Add 55ml of water and the mother liquor of Example 1 to the distillation residue to obtain 243g of phosphorous acid with a content of 98.1%.

Embodiment 3

[0037] Example 3: Embodiment 3 repeats the test of example 2 again: as figure 1 Shown:

[0038] 1) Add 180g of acetic acid and 306g of acetic anhydride to a dry and clean 1000ml four-neck flask, stir, cool down to below 20°C, add 830g of phosphorus tribromide dropwise, slowly raise the temperature to 30°C and keep it for 2 hours, then heat it up to reflux and keep it at reflux for 0.5 Hour.

[0039] 2) Start steaming at normal pressure for 7 hours, then distill under reduced pressure for 2 hours until no liquid is evaporated. Acetyl bromide 1090g was obtained with a purity of 98.2%.

[0040] 3) Add 55ml of water and the mother liquor of Example 1 to the distillation residue to obtain 246g of phosphorous acid with a content of 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com