Preparation method of triethylene glycol di-2-ethylhexoate

A technology of isooctanoate and triethylene glycol diethylene glycol is applied in the field of plasticizers to achieve the effects of inhibiting side reactions, simple methods, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

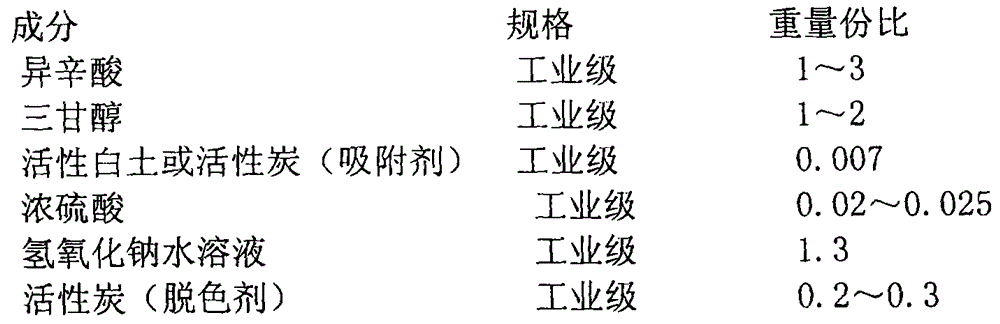

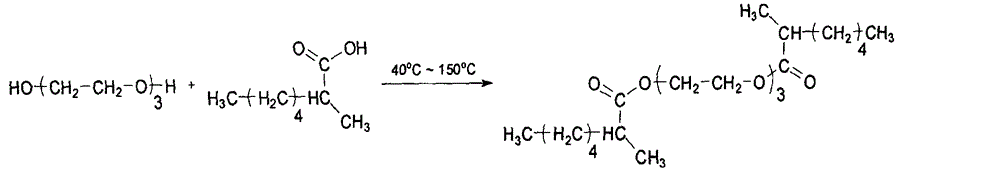

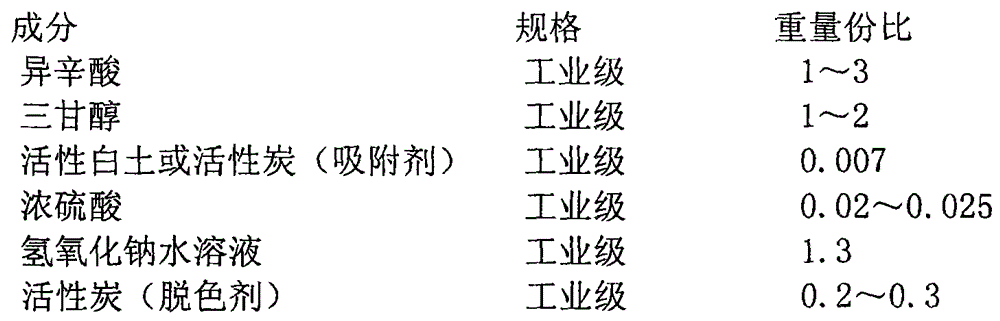

Method used

Image

Examples

Embodiment 1

[0017] Take a 500ml four-neck flask, equipped with mechanical stirring, oil bath heating device, install a condenser, a distillation head, and a thermometer, add 75g of triethylene glycol, 225g of isooctanoic acid, and 0.5g of activated clay, heat and stir, when the temperature rises to 40 ° C ~ 80 °C, add 1.5 g of catalyst and stir for 2 hours.

[0018] Continue to raise the temperature, control the temperature at 80°C-90°C, dehydrate under negative pressure, control the vacuum degree at 10mmHg-15mmHg, and react for 6 hours to obtain the esterification mixture;

[0019] The above-prepared esterification mixture was lowered to room temperature, and 100 g of 1.0% sodium hydroxide aqueous solution was added dropwise within 1 hour, and 5.0 g of decolorizing agent (activated carbon) was added. Distill under the condition of 1mmHg to remove excess isooctanoic acid, and then filter to obtain triethylene glycol diisocaprylate.

Embodiment 2

[0021] Take a 1000ml four-neck flask, equipped with mechanical stirring, oil bath heating device, install a condenser, distillation head, thermometer, add 75g triethylene glycol, 200g isooctanoic acid, 0.5g activated carbon, heat and stir, when the temperature rises to 40 ℃ ~ 80 ℃ When, add 1.5g catalyst, stir 2 hours.

[0022] Continue to raise the temperature, control the temperature at 90°C to 105°C, dehydrate under negative pressure, control the vacuum at 10mmHg to 15mmHg, and react for 4.5 hours to obtain an esterification mixture;

[0023] The esterification mixture prepared above was lowered to room temperature, and 100 g of 1.2% sodium hydroxide aqueous solution was added dropwise within 1 hour, and 4.5 g of decolorizing agent (activated carbon) was added. Distill under the condition of 1mmHg to remove excess isooctanoic acid, and then filter to obtain triethylene glycol diisocaprylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com