Polyurethane acrylate sealant and preparation method thereof

A polyurethane acrylate and sealant technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as poor adhesion, unsatisfactory use requirements, and unreasonable formula ratios, etc., to achieve The effect of good adhesion, reasonable proportion and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The polyurethane acrylate sealant of the present invention is made up of following components by weight:

[0038]

[0039]

[0040] The preparation method comprises the following steps:

[0041] A. Preparation of polyurethane prepolymer

[0042] Using a quantitative feeding device, add biuret polyisocyanate and polyether polyol in the reaction device at a mass ratio of 25:1, close the reaction device, stir, vacuumize and reduce pressure, and react at 40°C for 0.5 hours;

[0043] B. Preparation of polyurethane acrylate sealant

[0044] Add isooctyl acrylate, glycidyl methacrylate, isobutyl methacrylate, and vinyl acetate to the reaction device, stir and control the temperature of the reactor at 60°C, add tackifier and adhesion promoter, and use Cool the cooling device down to 30°C, add plasticizer, disperse evenly, filter through the filter device, and then use the automatic filling device to fill and store.

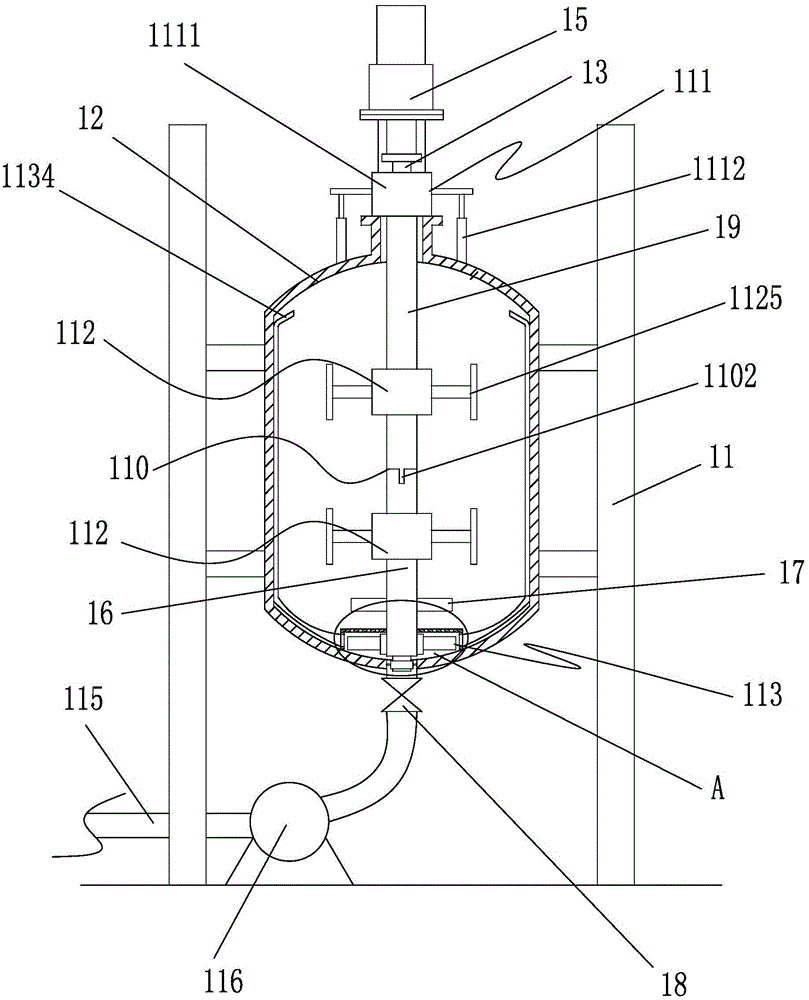

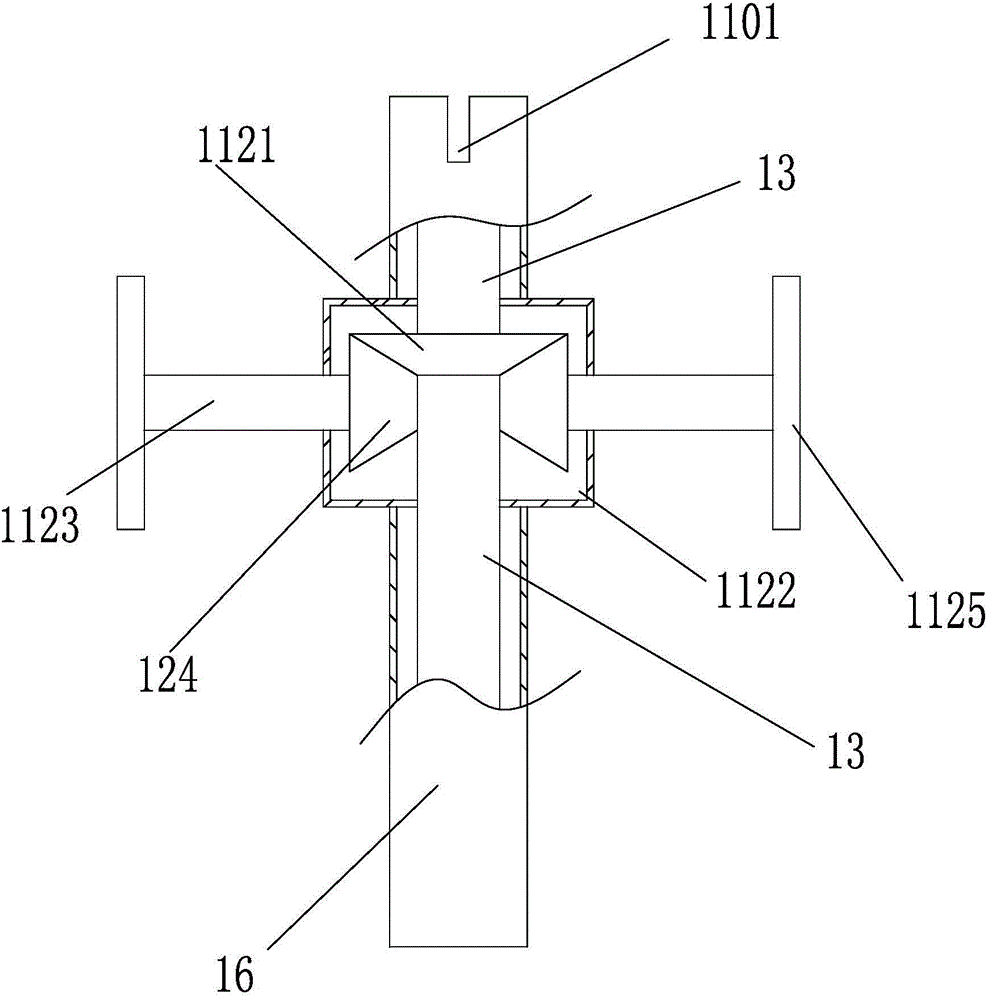

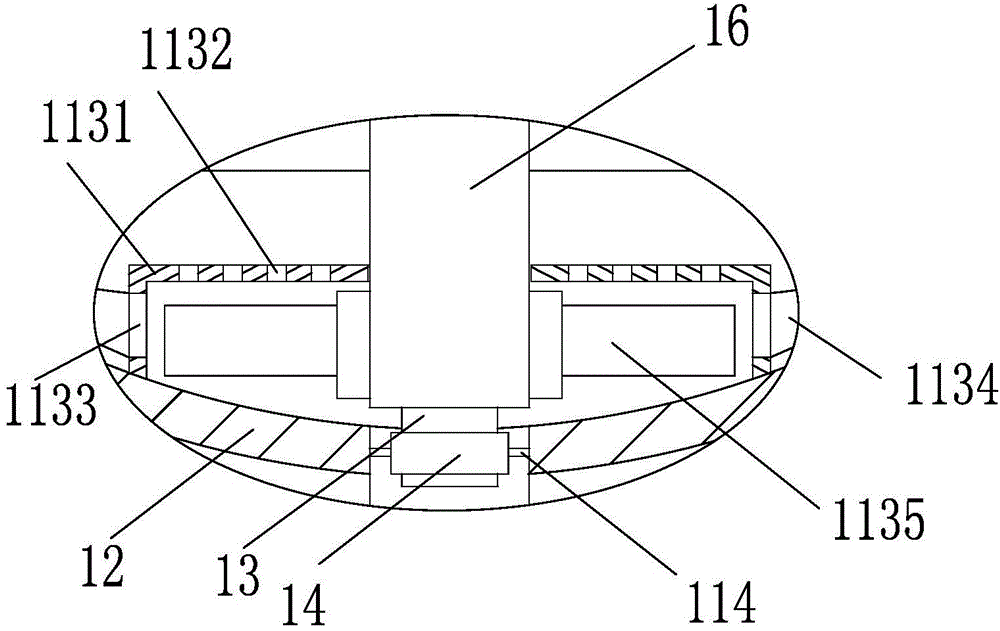

[0045] The reaction device 1 described in the presen...

Embodiment 2

[0061] The polyurethane acrylate sealant of the present invention is made up of following components by weight:

[0062]

[0063] The preparation method comprises the following steps:

[0064] C. Preparation of polyurethane prepolymer

[0065] Using a quantitative feeding device, add biuret polyisocyanate and polyether polyol in the reaction device at a mass ratio of 25:1, close the reaction device, stir, vacuumize and reduce pressure, and react at 40°C for 0.5 hours;

[0066] D. Preparation of polyurethane acrylate sealant

[0067] Add isooctyl acrylate, glycidyl methacrylate, isobutyl methacrylate, and vinyl acetate to the reaction device, stir and control the temperature of the reactor at 60°C, add tackifier and adhesion promoter, and use Cool the cooling device down to 30°C, add plasticizer, disperse evenly, filter through the filter device, and then use the automatic filling device to fill and store.

[0068] The quantitative feeding device reaction device, cooling ...

Embodiment 3

[0070] The polyurethane acrylate sealant of the present invention is made up of following components by weight:

[0071]

[0072] The preparation method comprises the following steps:

[0073] A. Preparation of polyurethane prepolymer

[0074] Using a quantitative feeding device, add biuret polyisocyanate and polyether polyol in the reaction device in a mass ratio of 1, close the reaction device, stir, vacuumize and reduce pressure, and react at 100 ° C for 3 hours;

[0075] B. Preparation of polyurethane acrylate sealant

[0076] Add isooctyl acrylate, glycidyl methacrylate, isobutyl methacrylate, and vinyl acetate to the reaction device, stir and control the temperature of the reactor at 80°C, add tackifier and adhesion promoter, and use The cooling device cools down to 50°C, add plasticizer, disperse evenly, filter through the filter device, and then use the automatic filling device to fill and store.

[0077] The quantitative feeding device reaction device, cooling d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com