A kind of plugging agent for drilling fluid and preparation method thereof

A technology for plugging agent and drilling fluid, applied in the field of plugging agent for drilling fluid and its preparation, can solve problems such as product failure, influence of drilling fluid rheology, etc., and achieve the effects of poor water solubility, avoiding aging failure and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Dissolve 15g of sodium humate in 90mL of water, adjust the pH to 8 with 3g of calcium oxide, and prepare a mixed solution of A;

[0021] 2) Add 15 g of calcium lignosulfonate and 2.5 g of 20% formaldehyde solution to the A mixed solution prepared in step 1, and react for 5 hours at 80° C. to prepare the B mixed solution;

[0022] 3) Add 10g of 2-methyl-2-acrylamidopropanesulfonic acid to the mixed solution of B obtained in step 2, adjust the pH value to 9 with caustic soda, add 0.2g of azobisisobutyronitrile, at 50°C , reacted for 5h to prepare a mixed solution of C;

[0023] 4) Dry the mixed solution C obtained in step 3 in an oven at a temperature of 90°C for 12 hours, pulverize it with a pulverizer after drying, and pass it through a 500-mesh sieve to obtain the plugging agent for drilling fluid.

Embodiment 2

[0025] 1) Dissolve 25g of sodium humate in 80mL of water, adjust the pH value to 11 with 4.5g of calcium oxide, and prepare a mixed solution of A;

[0026] 2) Add 25 g of calcium lignosulfonate and 5 g of 20% formaldehyde solution to the A mixed solution prepared in step 1, and react for 3 hours at 90° C. to prepare the B mixed solution;

[0027] 3) Add 15g of 2-methyl-2-acrylamidopropanesulfonic acid to the mixed solution of B obtained in step 2, adjust the pH value to 13 with caustic soda, add 0.3g of azobisisobutyronitrile, at 60°C , and reacted for 3h to prepare a mixed solution of C;

[0028] 4) Dry the mixed solution C obtained in step 3 in an oven at a temperature of 90°C for 12 hours, pulverize it with a pulverizer after drying, and pass it through a 500-mesh sieve to obtain the plugging agent for drilling fluid.

Embodiment 3

[0030] 1) Dissolve 20g of sodium humate in 60mL of water, adjust the pH value to 10 with 4g of calcium oxide, and prepare a mixed solution of A;

[0031] 2) Add 15 g of calcium lignosulfonate and 8 g of 20% formaldehyde solution to the aqueous solution prepared in step 1, and react for 5 hours at 90° C. to obtain a mixed solution of B;

[0032] 3) Add 12g of 2-methyl-2-acrylamidopropanesulfonic acid to the mixed solution of B obtained in step 2, adjust the pH value to 12 with caustic soda, add 0.3g of azobisisobutyronitrile, at 70°C , reacted for 5h to prepare a mixed solution of C;

[0033] 4) Dry the mixed solution C obtained in step 3 in an oven at a temperature of 90°C for 12 hours, pulverize it with a pulverizer after drying, and pass it through a 500-mesh sieve to obtain the plugging agent for drilling fluid.

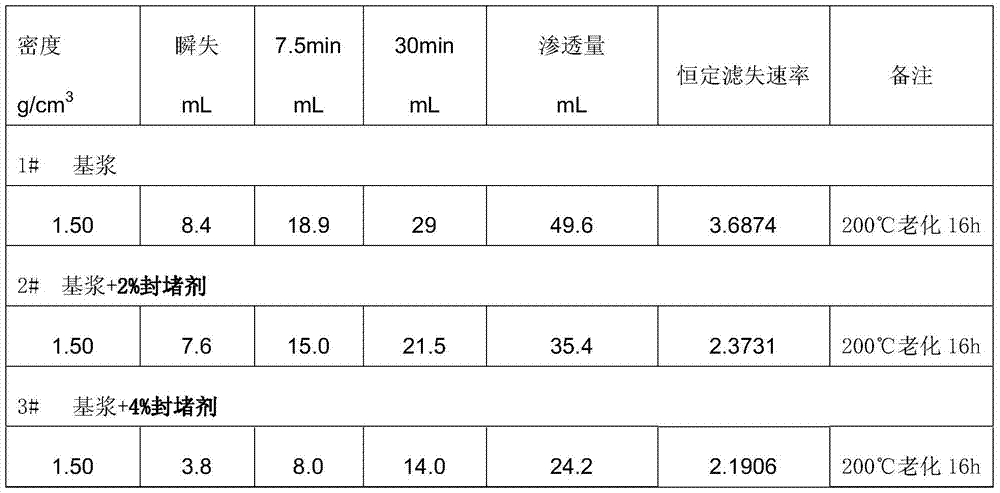

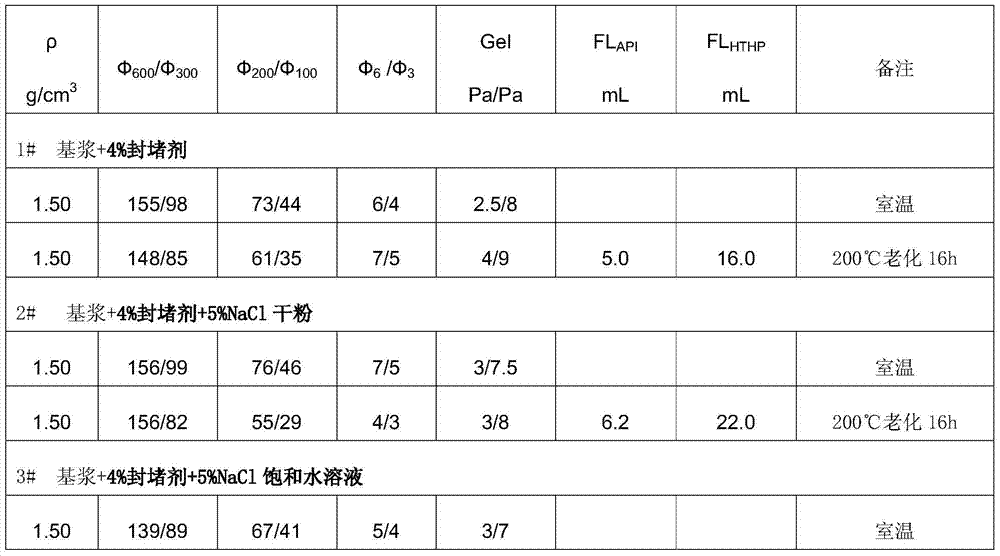

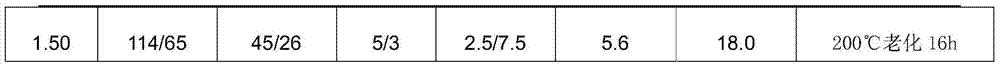

[0034] Effect Evaluation of Plugging Agent Used in Drilling Fluid

[0035] 1. Plugging agent plugging test

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com