Non-load starting device and method for variable hydraulic pump

A variable hydraulic pump, no-load start-up technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system safety, servo meter circuit, etc., can solve the hydraulic system pressure shock, hydraulic pump, hydraulic system and working device damage, The size and volume of the unloading device increase, so as to achieve the effects of small impact on the hydraulic system, small starting torque and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

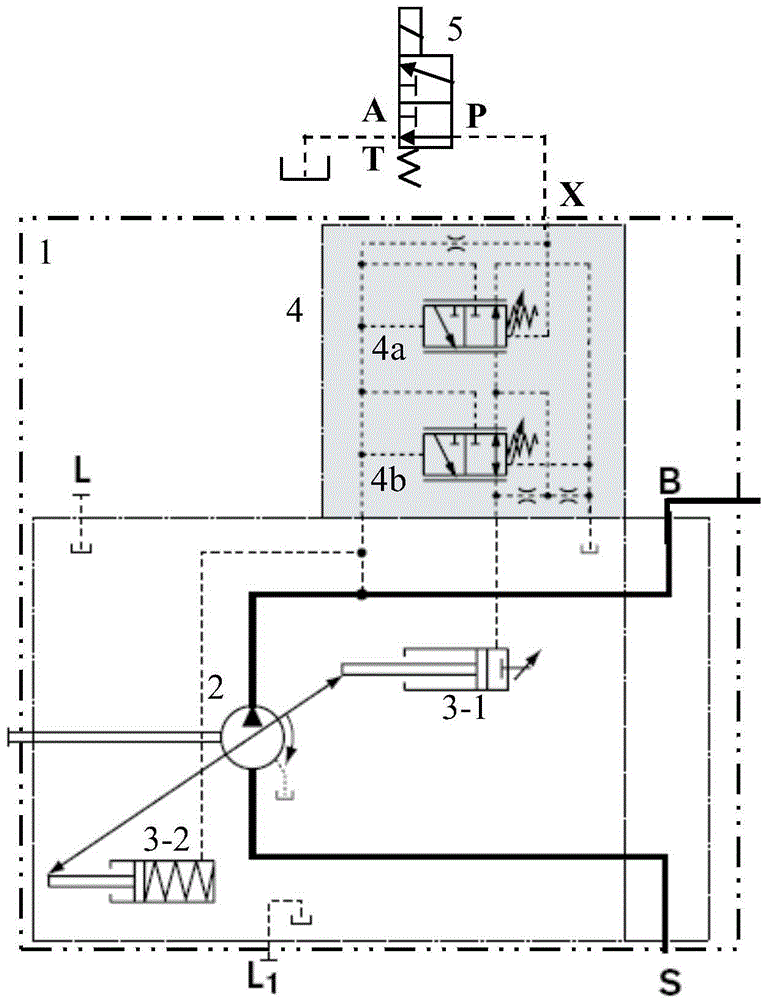

[0026] Such as figure 1 As shown, this embodiment is a variable hydraulic pump no-load starting device, the directional control valve is a two-position three-way directional control valve (5), and the variable hydraulic pump is a pressure-controlled variable hydraulic pump (1). The variable hydraulic pump (1) includes a hydraulic pump (2), a variable hydraulic cylinder (3) and a pressure control variable control device (4). A control port X is provided on the variable hydraulic pump (1), and the control port X of the pressure control variable control device (4) of the variable hydraulic pump (1) is connected to a two-position three-way directional control valve (5) with a small diameter. The P port of the two-position three-way directional control valve (5) is closed, the T port of the two-position three-way directional control valve (5) is connected to the fuel tank, and the first port of the variable hydraulic pump (1) The variable hydraulic cylinder (3-1) and the second va...

Embodiment 2

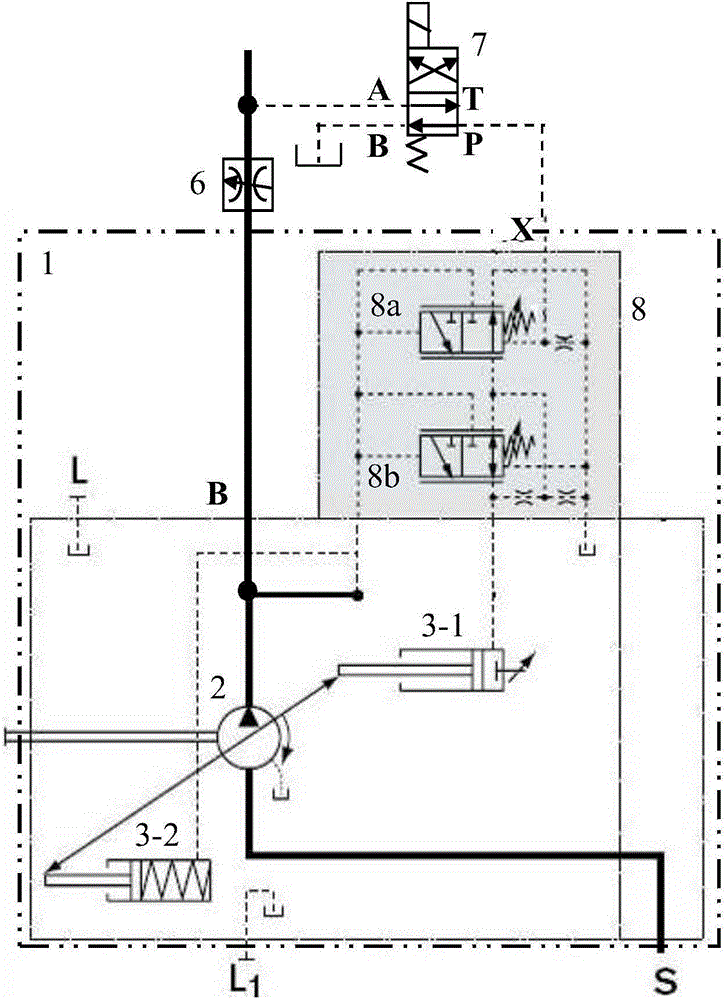

[0031] Such as figure 2 As shown, this embodiment is a variable hydraulic pump no-load starting device, the directional control valve is a two-position four-way directional control valve (7), and the variable hydraulic pump is a pressure / flow controlled variable hydraulic pump (1). The variable hydraulic pump (1) includes a hydraulic pump (2), a variable hydraulic cylinder (3) and a pressure / flow control variable control device (8). A control port X is provided on the variable hydraulic pump (1), and the control port X of the pressure / flow control variable control device (8) of the variable hydraulic pump (1) is connected to a two-position four-way directional control valve with a small diameter ( 7) Port P, the A port of the two-position four-way directional control valve (7) is connected to the outlet of the throttle valve (6), and the B port of the two-position four-way directional control valve (7) is connected to the oil tank, so The T port of the two-position four-way ...

Embodiment 3

[0036] Such as Figure 5 As shown, this embodiment is a variable hydraulic pump no-load starting device, the directional control valve is a two-position three-way directional control valve (5), and the variable hydraulic pump is a pressure / flow / power controlled variable hydraulic pump (1). The variable hydraulic pump (1) includes a hydraulic pump (2), a variable hydraulic cylinder (3) and a pressure / flow / power variable control device (9). A control port X is provided on the variable hydraulic pump (1). The pressure / flow / power control of the variable hydraulic pump (1) controls the control port X of the variable control device (9). The P port of the valve (5), the A port of the two-position three-way directional control valve (5) is connected to the outlet of the throttle valve (6), and the T port of the two-position three-way directional control valve (5) is connected to the oil tank , the B outlet of the variable hydraulic pump (1) is connected to the inlet of the throttle v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com