Special cabinet of helium gas recycling device

A technology of helium gas recovery and cabinets, which is applied in mechanical equipment, container discharge methods, gas/liquid distribution and storage, etc., can solve the problems of large space occupation, difficulty in connection, assembly and maintenance, inconvenient movement, etc. The effect of small space, convenient assembly and maintenance, and convenient assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

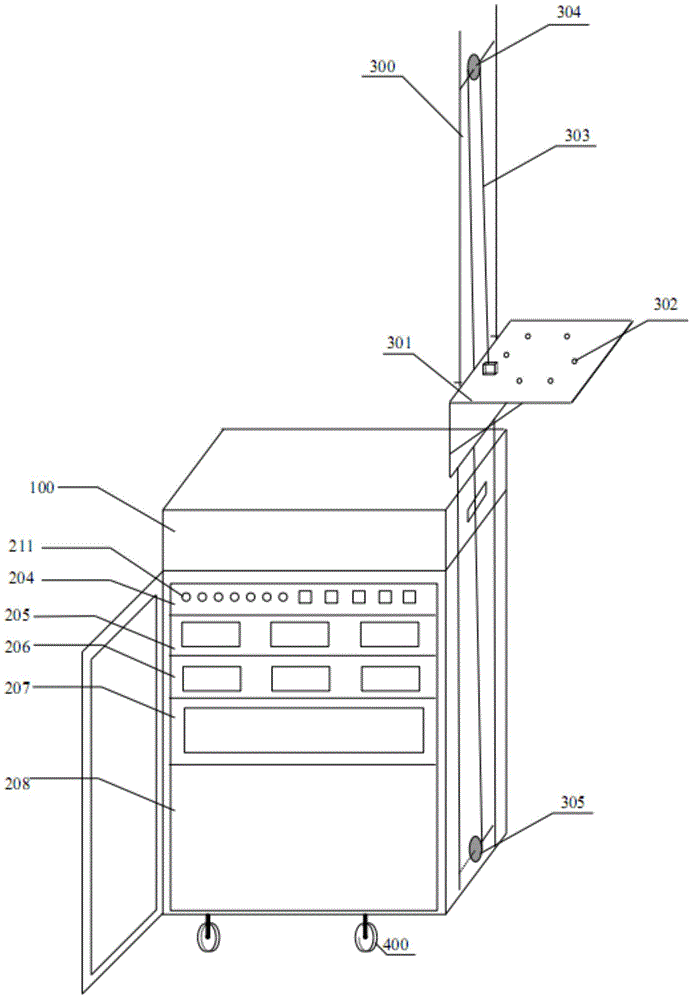

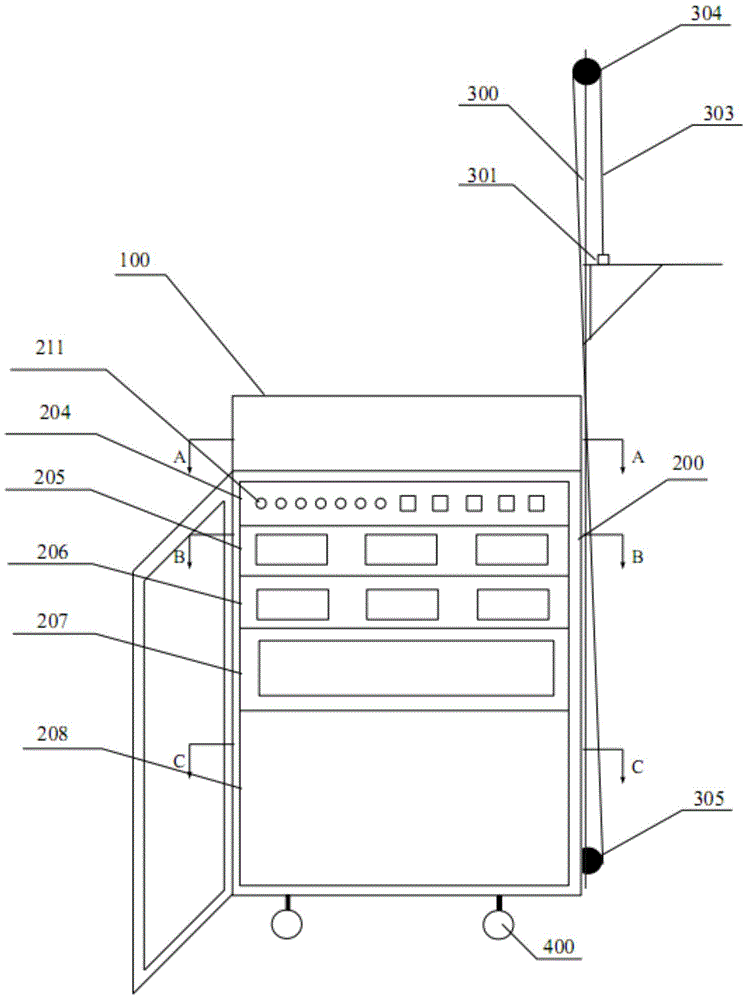

[0038] Figure 1-5 As shown, a specific embodiment of the present invention is: a special cabinet for a helium recovery and recycling device, and its structural characteristics are:

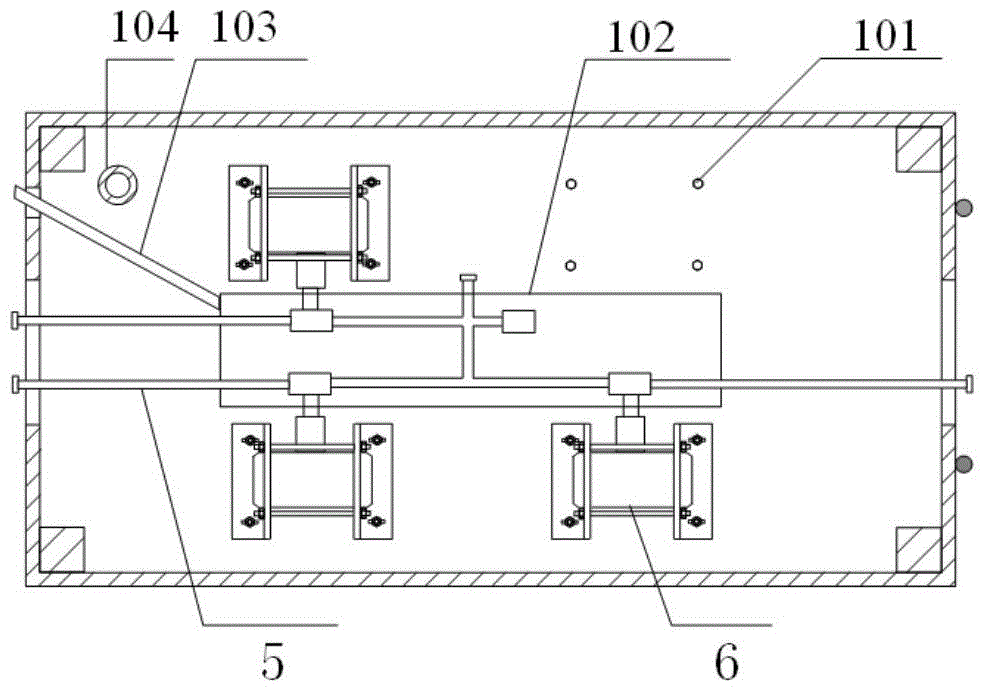

[0039] The top of the cabinet is a box body 100 with a top cover, and the bottom of the box body 100 is fixed with threaded holes 101 for installing three electric ball valves, and a water diversion plate 102 is placed between the installation positions of the three electric ball valves at the bottom of the box body 100, The water diversion pipe 103 on the side of the water diversion tray 102 passes through the box body 100; the bottom of the box body 100 is provided with a lead pipe 104 that passes through the box body and enters the inner cavity of the cabinet body 200;

[0040] The inner cavity of the cabinet body 200 is divided into five layers by the partition plate 201, and the adjacent layers are connected through the lead hole 202, and the cabinet body 200 is connected with the outside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com