High temperature sintered electrode paste for led glass filament

A technology of LED glass, high temperature sintering, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., to achieve good thermal expansion matching, high printing resolution, and good solder resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

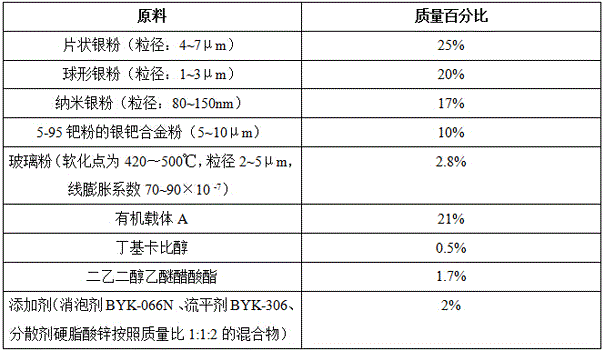

[0031] The high-temperature sintering electrode paste for LED glass filament, its formula composition is as follows:

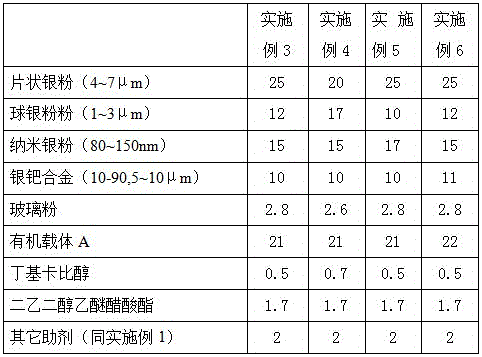

[0032] Table 1:

[0033]

[0034] Among them, organic carrier A is composed by mass: ethyl cellulose 4%, hydrogenated castor oil 3%, castor oil 1%, terpineol 35%, butyl carbitol 37%, diethylene glycol ether acetate 20% .

Embodiment 2

[0036] The high-temperature sintering electrode paste for LED glass filament, its formula composition is as follows:

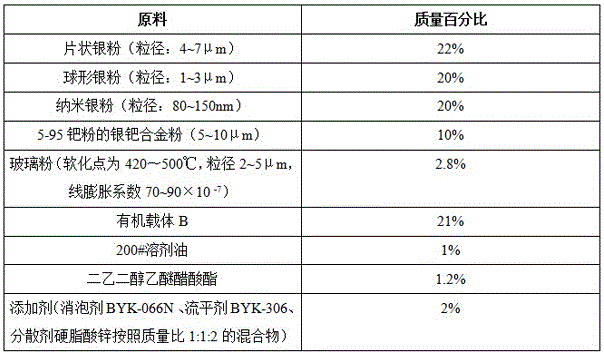

[0037] Table 2:

[0038]

[0039] The organic carrier B is composed by mass: 3% ethyl cellulose, 5% PVB, 2.5% hydrogenated castor oil, 43% terpineol, and 46.5% butyl carbitol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com