Organic carrier for crystalline silicon solar cell electrode paste and preparation method thereof

A technology of solar cells and organic carriers, applied in conductive materials dispersed in non-conductive inorganic materials, applications, household appliances, etc., can solve the problem of ignoring the recovery of shear thinning intrinsic viscosity of the slurry, increasing the shading of electrode grid lines Area, affecting conversion efficiency and other issues, to achieve the effect of improving rheological properties and process performance, low cost, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

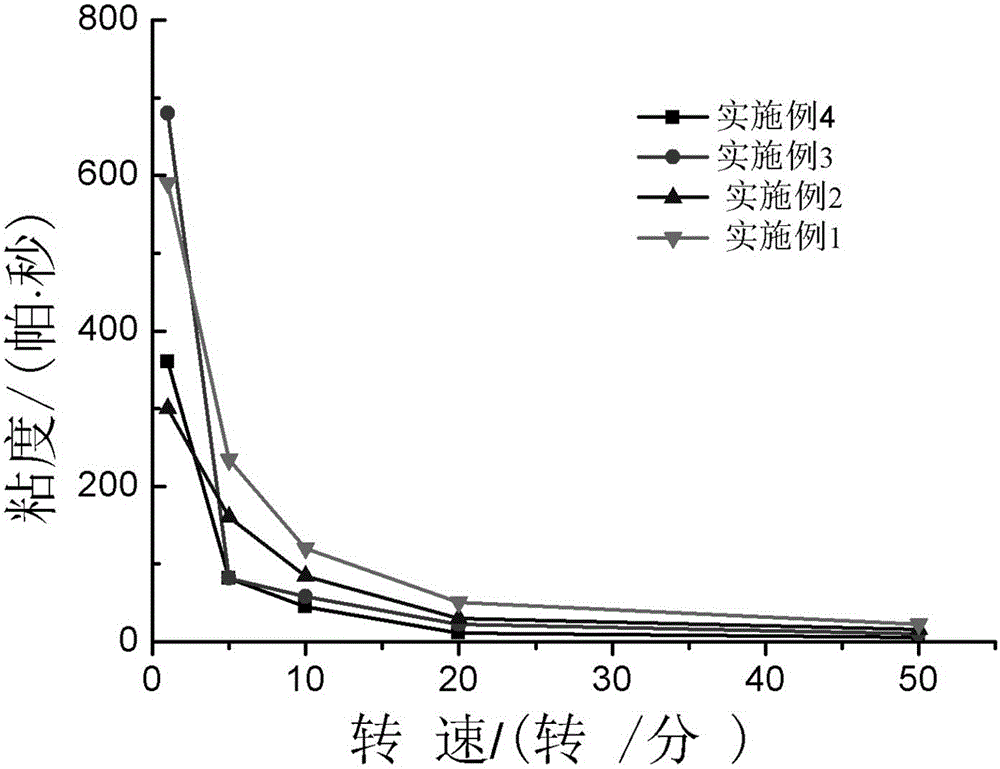

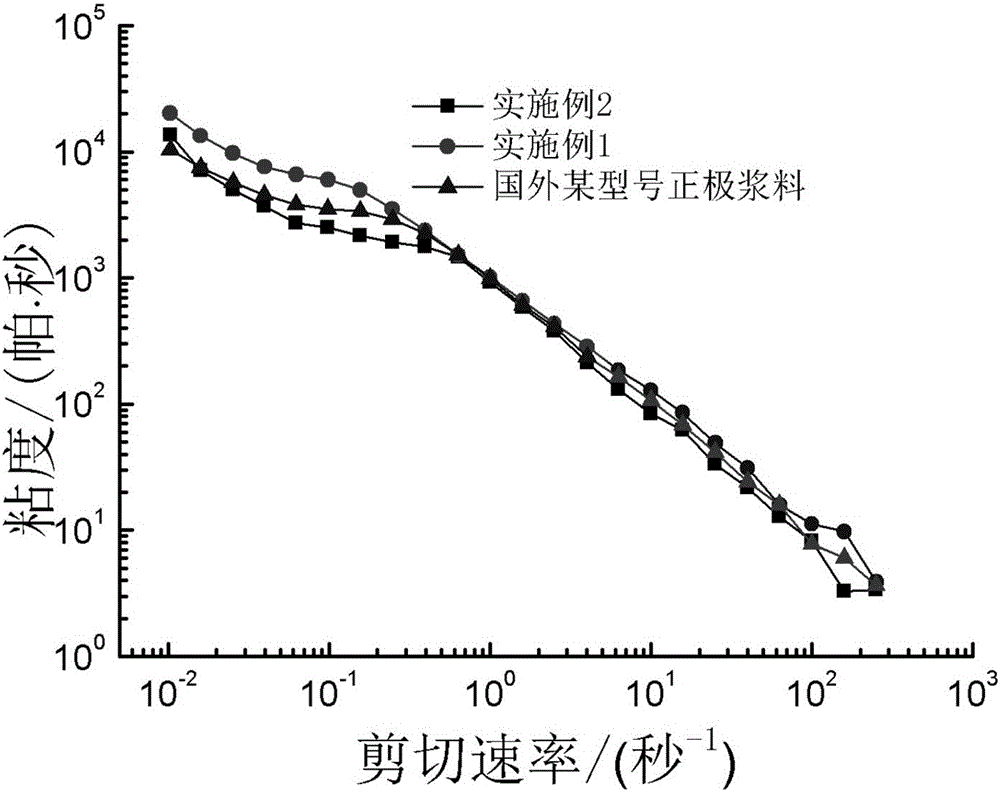

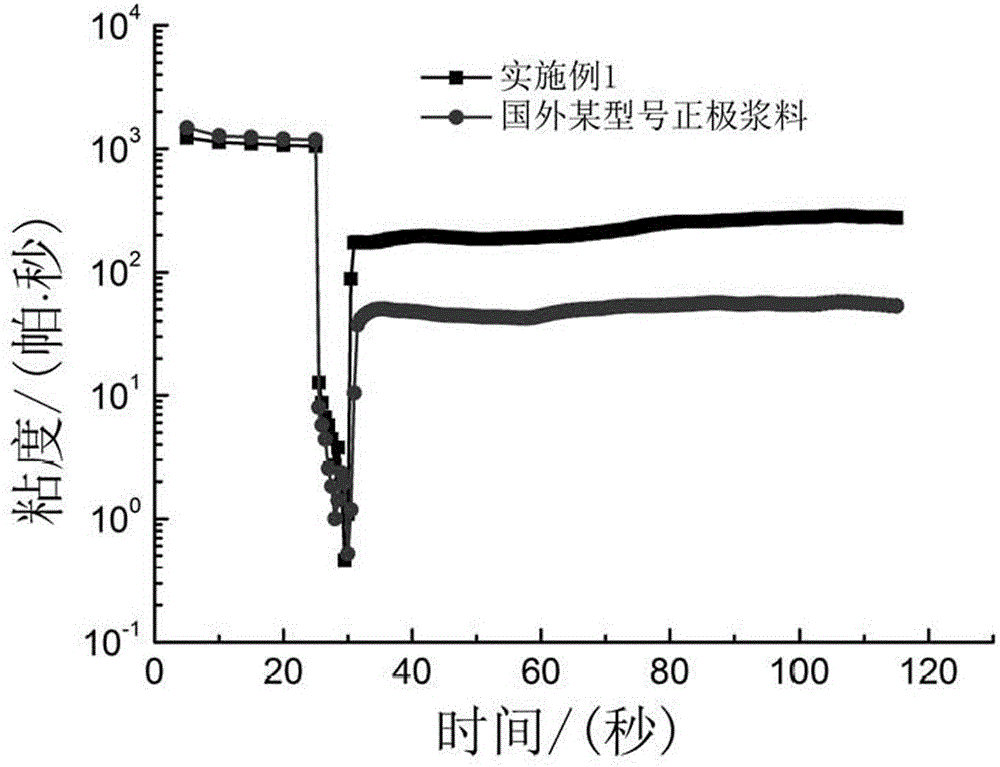

Embodiment 1

[0039]An organic vehicle for crystalline silicon solar cell electrode paste of the present invention comprises the following components: 1.04g organic resin, 9.07g organic solvent, 0.5g thixotropic agent and 0.5g wetting and dispersing agent, wherein the organic resin consists of 0.187 g ethyl cellulose 200, 0.053 g ethyl cellulose 300 and 0.8 g acrylic resin NeoCryl B-723, the organic solvent consists of 5.57 g alcohol ester dodeca (i.e. 2,2,4-trimethyl-1,3- Pentylene glycol monoisobutyrate) and 3.5g dimethyl nylon acid (DBE), the thixotropic agent is 0.5g polyamide wax MT ST, the wetting and dispersing agent is 0.5g N-tallow-1,3- Propylenediamine dioleate, HLB value 12.

[0040] A method for preparing an organic carrier for the above-mentioned crystalline silicon solar cell electrode paste of the present invention, comprising the following steps:

[0041] (1) Dissolution of organic resin: Weigh 0.187g of ethyl cellulose 200, 0.053g of ethyl cellulose 300 and 0.8g of acrylic...

Embodiment 2

[0049] An organic vehicle for crystalline silicon solar cell electrode paste of the present invention comprises the following components: 2.86g organic resin, 15.103g organic solvent, 1.0g thixotropic agent and 0.5g wetting and dispersing agent, wherein the organic resin consists of 0.28 g ethyl cellulose 200, 0.08 g ethyl cellulose 300 and 2.5 g acrylic resin NeoCryl B-842, the organic solvent is composed of 8.355 g alcohol ester dodeca and 6.748 g DBE, the thixotropic agent is 1.0 g polyamide wax MT ST, wetting and dispersing agent is 0.5g N-tallow-1,3-propanediamine dioleate, HLB value is 12.

[0050] A method for preparing an organic carrier for the above-mentioned crystalline silicon solar cell electrode paste of the present invention, comprising the following steps:

[0051] (1) Dissolution of organic resin: Weigh 0.28g of ethyl cellulose 200, 0.08g of ethyl cellulose 300 and 2.5g of acrylic resin NeoCryl B-842 as organic resin components, 8.355g of alcohol ester dodeca ...

Embodiment 3

[0058] An organic vehicle for crystalline silicon solar cell electrode paste of the present invention comprises the following components: 2.86g organic resin, 17.488g organic solvent, 1.0g thixotropic agent and 0.5g wetting and dispersing agent, wherein the organic resin consists of 0.28 g ethyl cellulose 200, 0.08 g ethyl cellulose 300 and 2.5 g acrylic resin NeoCryl B-805, the organic solvent is composed of 10.74 g alcohol ester dodeca and 6.748 g DBE, the thixotropic agent is 1.0 g polyamide wax MT ST, wetting and dispersing agent is 0.5g N-tallow-1,3-propanediamine dioleate, HLB value is 12.

[0059] A method for preparing an organic carrier for the above-mentioned crystalline silicon solar cell electrode paste of the present invention, comprising the following steps:

[0060] (1) Dissolution of organic resin: Weigh 0.28g of ethyl cellulose 200, 0.08g of ethyl cellulose 300 and 2.5g of acrylic resin NeoCryl B-805 as organic resin components, 10.74g of alcohol ester dodeca ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com